I searched and only found articles pertaining to using kerf adjustment, and “how to” but i was curious if people recommended adjusting the kerf settings in Lightburn Vs. Fusion 360. I’m designing in 360 and wasn’t sure if it mattered, if there’s a pro/con to each. Thanks in advance.

As a general rule, I think they design with cad the exact size and let lightburn adjust the kerf. Much the same as an engineering design is the actual size, the operator has to adjust for the kerf of the tool.

The benefit is that it’s an easy change, compared to re-running the changes in the cad and port them over to lightburn. One of the drawbacks is if you have multiple meeting parts the whole part has to have the same kerf. That’s because you can only apply a kerf to a ‘closed object’ in Lightburn.

When I use one of the sites like the universal box generator and it computes all of this and you just cut it out, as is.

I think in the end, it depends on the acceptable work flow for the project.

Some things will work better if you need to change something like the material thickness. This would affect the ‘finger’ length. That is usually done with a parametric cad program so it can recompute the parts.

This is difficult in Lightburn.

Hope I didn’t confuse you more…

Good luck

![]()

haha, no not at all I appreciate the response and details.

For my part, I’m fine with LightBurn`s kerf tool. But, as Jack writes, all shapes need to be closed, that’s sometimes a problem for me. The other element to be careful of is not to dazzle kerfettings from other programs along with those from LB.

I have tried a few times, ad boxes made in Boxes.Py, have got (further) my own “standard” 0.075 kerf from LightBurn which then ends up with 0.175.

I had problems with the boxes generator and found that the entry I assumed was a ‘kerf’ wasn’t.

Once I found that out, it makes pretty tight boxes… Every now and then it has a ‘strange’ shape that’s created.

I had to work with it a bit to figure it out.

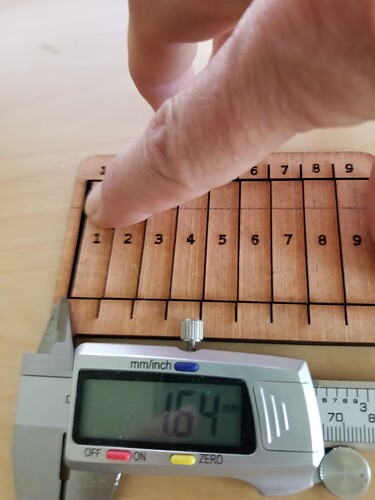

@Paying4Rhystic I have this I use to measure the kerf for a specific lens/material…

These are a couple of old pictures. I wised up and put material thickness, date/time and lens on them now…

kerf-master-00.lbrn2 (73.2 KB)

Take care

![]()

… small spikes at corners ??? ![]()

Yes, not only that, I had circles that the centers connected to the outline…

Pretty odd. I contacted the author he advised it was probably a rounding error…

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.