Good Day ! I use LightBurn software, and I’m using a Outur Laser Master 2 - 20 watt. I have downloaded a set of files to make a box and the creator offers the cut files in two different ways for you to use. One set of files is made with a kerf of 0 and the other set of files he says he already added a kerf of 0.15mm. When I go to snap the pieces together they are just a little to tight. What could I use as a kerf setting in LightBurn to make them just a little smaller. I don’t need much to make the pieces fit. I have, so far ,not used the kerf function , but see where I can change the settings. What do you think would be a good kerf setting to try ? Thanks George

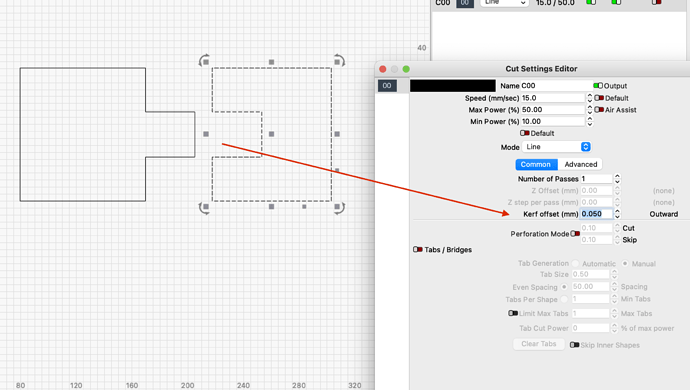

I would recommend that you do a test with the same material to find out how wide your laser beam is. Draw 2 shapes that are closed !, design should look like a fingerjoin. Then you can try different kerfsettings until you find the one that suits you. I guess it is between 0.03 and 0.05mm. Once you know your beam width, you can use the number as a reference in the future to determine your kerfsetting.

Thanks for that test info , I will try that tomorrow , I need to know how wide the bean is for sure. George in Fla

I use this to determine kerf for a specific material.

kerf-master-00.lbrn2 (71.4 KB)

Don’t forget to dived by 10…

Good luck…

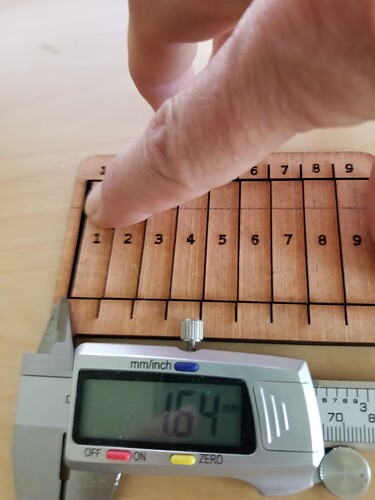

![]()

Thank you guy’s for your explanations on how to go about finding the laser beam size so I can adjust for the right kerf size . I’m useing a Ortur Laser Master 2 -----20 watt and after cutting on a 3mm baltic birch plywood I came out with a laser beam width of approx 6.5 thousands. This more than likey will be alittle different for different kinds of materials. Thanks ! George in Fla.

Absolutely.

I have kerf measurements for all lenses and a number of materials.

Take care

Good luck

![]()