I have a dumb question: I think since my Bi-Lateral knee surgery my brain has gone dead also.

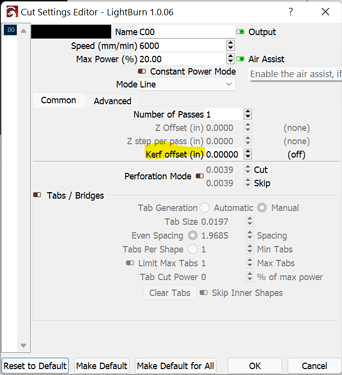

Where do I set the kerf in LB? I am wanting to do some jigsaw puzzles.

The actual kerf setting is found within the cut settings for a line operation. Check in the cut settings.

Thank you.

I obviously need to cut with a very narrow kerf for jigsaw puzzle cutting. To make the kerf smaller/thinner should i make it a negative or positive number? I seem to remember someone having said they set theirs at .001, that is thin!

Take some leftovers and try them out, I think every delivery of wood requires a little adjustment here with me. By the way, I use + 0.075mm as a starting point.

Thanks a million. Really appreciate your info. And: MERRY CHRISTMAS!!!

I think you may be misunderstanding how kerf works based on what you’re describing.

Kerf will not make the laser beam width wider or thinner. The cutting width of a single line is however thin the laser light focus can manage. This is affected by the source of the laser, the lens, focal distance, focus, etc.

How kerf works is by accounting for beam width by cutting outside of the intended shape by half the size of the kerf. So imagine a square of 10mm and a kerf of 1mm. The laser would actually cut a 11mm square so that the resulting material would measure 10mm.

In your jigsaw example, if you can’t get the pieces to fit as tightly as required while cutting in-place, you’d have to cut each piece out separately from non-connecting areas of material. Obviously not ideal for a puzzle.

Hoping this makes sense.

Thank you too and take care of your new knee !! Hope you are not in so much pain.

What actually confused me was the effect inner and outer would have on the puzzle pieces. I ran our CNC for 30 years before we retired. Had to adjust the kerf every time I ground the bits.

Have a Cloudray compound lens on my OMTECH 60W/50W. Will need to do some “fiddling” to get focus where it needs to be.

Thank you for the info.

I am one of the lucky ones I guess. My wife just about passed out when I told her I wanted to have both at the same time. Surgery took 2 1/2 hours and I spent 2 weeks in hospital rehab, smartest thing I ever done. I have zero pain unless I do something stupid. I walked without anyone holding on to me nine days after surgery. Will be five months the 20th of this month. I have cut and split wood, removed a garden fence, built fence, and walk for at least two hours without resting. My knees are steel.

Of course you are right, you must always cut out the two parts together which must fit together, the kerf setting is distributed on both sides.

A good example is a finger joint, what you cut out fits perfectly with the other part which is also cut out and not what is left over in the original material you cut both parts from.

I’ve made quite a few puzzles and do not think kerf is a problem here. Of course, your laser should be well focused, but a puzzle should not be too tight either.

That sounds great, I’m glad to hear that.

Assuming you’re cutting the pieces in-place you probably want no kerf at all.

If the pieces of the puzzle are modeled as separate pieces you’ll want to make sure that “Remove overlapping lines” is selected in Optimization Settings so that LB doesn’t attempt to go over the same cut line twice. Not an issue if the lines run continuously across the full width and height of the puzzle.

One last thing, I believe kerf only applies to closed shapes. Meaning it doesn’t have meaning on a single line. It needs to be a fully enclosed shape.

Sounds like you’ve had an incredible recovery. Good on you.

You don’t have a choice in kerf cutting out a puzzle. The kerf is simply the width of the ‘blade’ or in this case the laser beam.

Assumption that you were making two parts fit together. A puzzle is not the same type of procedure for manufacturing.

Not the same as cutting a puzzle out of a photo.

When you make one pass and cut a part with a jig saw, the two parts fit together fine. The only ‘clearance’ needed is the ‘kerf’ of the jig saw blade, which you can’t really control.

![]()

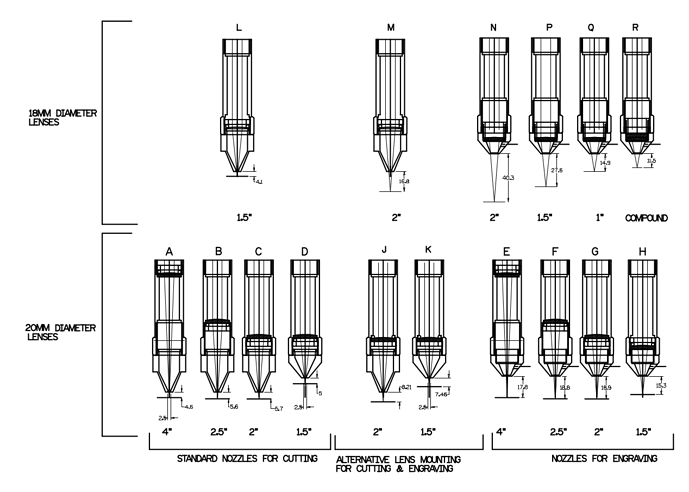

I am going to assume that the compound lens I have with a focal length of 10.5mm is more ideal for engraving than cutting. What focal length would be considered more or less ideal for cutting wood. That may be plywood or solid wood such as basswood for instance.

Seems that the longer focal length would make it possible to adjust for a very fine line, am I correct?

The compound is for engraving. And mine is 11.5mm…

Generally it’s considered that a longer lens will keep a ‘same size’ cut over a longer distance.

I find my 4" works well. I have the ‘stock’ 1.5" and also a 2". I find myself using the 2" for many things that include a cut. So I like the 2" best, but generally don’t cut over 6mm.

Here is a general guideline. It from Russ Sadler and his system that uses the ‘C’ series down tubes. But this may help you with some visualizations.

Good luck

I really ned some help on my venture. I have Cloudray combination lens and I would like to stay with them.

I want to get the 18mm 2" lens nozzle and lens for cutting/engraving. I do not understand what I need to order.I do not wish to buy the entire head. Anyone with experience with their product pages would be greatly appreciated.

My following dissertation in no way is a for/against Cloudray.

I asked Cloudray for guidance on what I needed to install a 2" 18mm 50.8mm lens on my Omtech 60W/50W CO2 laser. To make a long story short, after at least 20 t0 25 e-mails I received a notice today that my order had been shipped(from China). The copy of an order included in the e-mail was not what I ordered. Communicated with lady I had been conversing with and she assured me the order was what I ordered and not what was on the e-mail. I hate to be so scheptical and I will wait to raise cain with them until it arrives and is indeed the wrong items but I smell a rat and an order I am going to be very unhappy with. Before anyone suggests that I had bought from Amazon, normally you don’t get very good results from technical questions about product. I was in a quandary as to what I needed and supposedly the lady at Cloudray was capable of fulfilling my order with what i need. Oh! How I hope I can say MERRY CHRISTMAS in about a week.

MERRY CHRISTMAS EVERYBODY! I got the correct pieces from Cloudray!!!