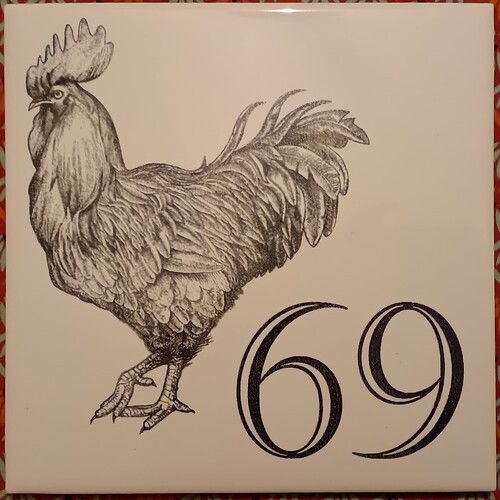

bonjour à tous , bravo pour vos explications et vos réalisations

pour mes gravure avec un laser co2 80 watt j obtiens de trés bon résultats , peinture aérosol apprêt blanc de chez Action 2.2€

vitesse de gravure 80mms

puissance maxi 14

puissance min 8

dpi 300

bonne continuation merci

Thank a lot Bill for sharing the tips !

I’ve wrote to Zinsser, to know what is the name of this product in Europe, to buy some.

Hey Scott, is that correct about it being 55mm per minute? That would be less than 1mm per second. 1mm is .040”…let me know if the travel speed is correct, at 55mm per minute, thanks!

Charlie

Sorry per second

Hey Tom. I bought some Rustoleum Cold Gavinizing Compound to etch on Glass and mirrors. I decided to do a test tile of it. It burns off the glaze and exposes the naked tile, and I am sure it would soak up whatever. Not good for making black on white tiles, but may be good for what you’re thinking.

To make sure I understand… You first put down Rustoleum Flat White paint, then a layer of the Zinsser water-based primer. Yes?

I had the Zinsser spray primer completely fail for me. I’m assuming it was applied too thickly, so I just sprayed another set of tiles to try again with a thinner coat.

Yeah, for me the cold galvanizing compound produced browns, not blacks, on white gloss tile. I’m still in the testing stages, but so far, Rustoleum Flat Gray Primer spray is my winner on test grids.

Did you ever gotten a reply from Zinsser?

Heads up! Know that there’s 1-2-3 Primer, and there’s 1-2-3 PLUS Primer.

Looks like though both are “water-based”, the PLUS primer is solvent-cleanup, where the standard primer is water cleanup. This could well be why I almost needed a chisel and sand paper to remove the PLUS.

On the up side… I know what primer I’m using for my home projects!! That PLUS primer is amazing…

I had initially heard about Krylon flat white but when I went to Home Depot (closer to me and my preferred store) all they had was Rust-oleum Flat white, so I got that. I remembered afterward Lowes carries Krylon. Anyway I tried the rus-oleum flat white and it works fine for me. This is on my Atomstack X7 10w. I did a test burn (the dithering test, the one with the eye balls on it). I found the Atkinson dithering looked best for me. But I will try the Zinsser soon.

im very late to this party but i found Zinser 123 has 15% TiO2 content by using the SDS documents https://www.rustoleum.com/msds/techdocs/nz/SDS/en/285278.pdf , it seems like up to 30% content is ideal for light scattering … Titanium Dioxide - TiO2 Pigment for Paints, Coatings & Inks

Does anyone have an updated method to share ?

I am using a homemade formula I found on youtube. 1 part TiO2 powder, 1 part Elmers white glue, 3 parts water. I mix the water and TiO2 first then add the glue. If it seems a little thin I either add some white Apple Barrel (Wal Mart) paint or some more glue. I use an airbrush to apply it, but have seen others use a foam brush. Nice part is it cleans up with soap and water. Have had good success with it. Just need to mix well and apply an even layer. I add some dye to the mixture so I can get a better feel on the coverage.

Im thinking of using PVA mold release as the binder and running 30% Tio2 as a trial PVA Mould Release Agent - Easy Composites , i asked two local paint companies what paint has the max TiO2 content in their range to see if i can get close to 30% out of that option too . Trial and error may well turn out better than spending some time trying to understand and nerd out on the exact formula and thickness but nailing it down is probably going to be some of the fun for me. I certainly have no issue starting where others left off though using a solid formula like yours Rob. PVA release is a bit of a pain if you try to heat it to speed up the drying it cracks and if you leave it too long it can come off the surface, however it is a good consistency to spray and i have some.