I have found a supplier of various honeycomb bed material at very fair prices.

from easy composites in the uk supplied in block form ie 1250 x 626 aluminium 3/4 inch is £16.25 plus postage and vat.

it comes in a solid block which you have to stretch to get 1250 x 625 which can them be cut with scissors to get 2 at 600 x600 .

it works great and after 4 months i am still on the first piece.

I have to comment, so take it as you please… I thought this was better than sliced bread… however…

I know of no good reason for honeycomb beds, except to increase the chance of fire.

It totally disrupts the air flow within and through the machine. There is no air flow inside each of the cells, so debris condenses on the inside of these.

Being honeycomb, they are difficult to clean, unless you soak them in a solvent.

If you don’t raise you material above them, every place the laser strikes the bed, it leaves a mark on your material.

Made out of aluminum, there is no way to use magnets, so you end up making specialized parts to secure the work.

Mine lasted a day, then I went to the local steel vendor and bought a sheet of steel that will fit into the hole. It cleans up with a rag and solvent very easily and doesn’t stink up the machine. It fits so snug I’ve drilled alignment holes in it for jigs… Cost me $12 US.

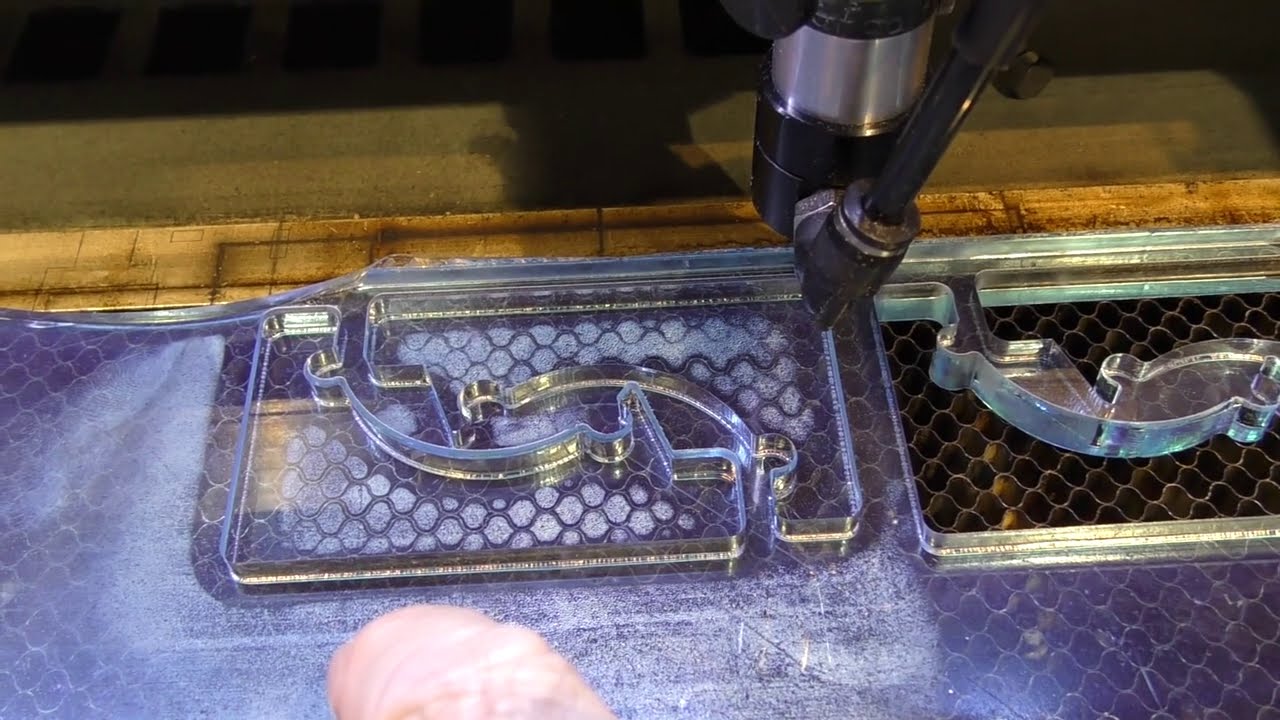

This one is ~15 minutes…

This is ~3 minute video that you can see how it works… or really how it doesn’t work. The acrylic gases are burning here, but it very similar with wood…

I’ll get off my soapbox now…

Have fun.

![]()

Thats why i set the honeycomb on 3mm rails on a 3mm steel plate with no problems at all i just lift the comb to clean . No burn marks good cuts and no hassle.

Great it works for you… surprised you don’t get reflection marks when cutting.

It has to disrupt air flow…?

How do you clean it?

![]()