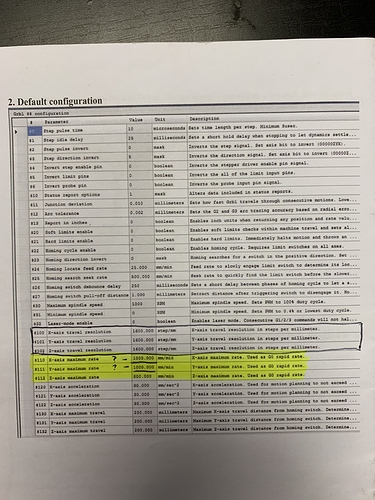

According to the attached picture, your stepper resolution probably is wayy to high! The most common is 80 or 160 (at 16 microsteps, check your driver configuration how many you have). Basically, this value is obtained by your gear size, microsteps and some other things. Start with one of the values above and then tweak them. If it’s printing right with “1600”, don’t change them and just tweak them! Simply design a 300x300mm rectangle or some other size (not to small), laser it and measure it. If it meaures 300 perfectly, the value you set is spot on. If it’s more (or less) than it’s supposed to be, tweak the value. X and Y aren’t the same value, you must tweak them individually.

The “secret” formula to get the right numer on the first try is to measure the printed out rectangle and putting it in following “formula”:

(Designed_Size / Actual_lasered_size) * Current_resolution

For instance, if the resolution is set to X = 80 in GRBL, you design 300mm (in the X axis) and it comes out with 301, the formula would be:

300 / 301 * 80 = 79.7342

Set the value writing just $100=79.7342 and press enter. It should reply with ok (in above case). If you have a program for communicating graphically with GRBL, just type it in and save.

The acceleration with my particular laser is 2500, but the heavier your laser head is, the slower this value must be. This value is there to “ramp” your steppers up to speed, so they don’t loose steps. Too fast, it stalls (makes noise and doesn’t move properly) and you’ll loose steps, to slow and you’re wasting time for no reason and possibly burning edges and steep angles where it slows down and speeds up slowly for no reason.

ProTip: Also, when lasering and setting speeds in LightBurn or any other G-Code program, if you put in acceleration values too fast, but still within your defined GRBL configs, it can occurr that it lases without loosing steps, but jittering at steep angles or edges. If that occurrs, make it slower in your software. Don’t need to change it in GRBL, since fast moves while just going to a position is good

I personally start a not too low value (for lighter setups to 1000 or above) and start incrementing 100. If the motor starts to stall while it’s moving at it’s maximum speed, go back down quite a bit, maybe 30% under that value. After all, it should be sturdy while moving and not stall if you just “touch” it. The faster it goes, the less torque it has, so it gets more sensitive to loosing steps the faster you go. Don’t worry about the noise when it stalls, this shouldn’t harm your steppers or laser, it’s just the motor which is loosing steps and that’s purely magnetic.

The maximum travel is literally the bed size in mm. Just set them both to 1000 or so and advance the laser slowly until you get to the very far edge of the bed, then you have your values. Overwrite the maximum travel with those and you’re good to go! Do this only after you’ve set the resolution, should be obvious.