Since I have updated the Lightburn Software to the new version 1.4.03 a project that I have done many times before with no issues, is now incinerating random areas of the project. I don’t know what has changed or how it could be doing this. I have an Omtech 60 Watt 16X24 and have never seen this issue before. Anyone seen anything like this before?

Without any changes to the configuration or the LightBurn file, the problem is unlikely to have anything to do with those, so hardware is the immediate suspect.

If you’ve been using the laser for a couple of years, the tube is likely to be reaching the end of its lifetime and has begun operating erratically. Because it’s intermittent, this may be hard to verify, but the general process is to measure the beam shape at the first mirror.

A quick introduction:

A simpler problem could be focus lens working loose (or shattering!) inside the laser head. Take a look in there to make sure everything is OK.

While you’re poking around, check all the mirrors to verify they remain properly secured and aligned.

Also: are the pictures oriented the same way they’re engraved, with the scanning direction going left-right across the picture?

The pictures came thru oriented in 90 degrees from what I engraved them too. Looking at the picture it would be up and down, but we know it is side to side. The laser is only 4 months old and has only 250 hours on it. I will check the mirrors and the main focus lens to see if there is any issues.

So the tube might still be within OMTech’s 6 month warranty.

Get OMTech involved now to establish the problem’s timing, find out what they recommend, and keep that iron warming in the fire while you discover what’s actually going on.

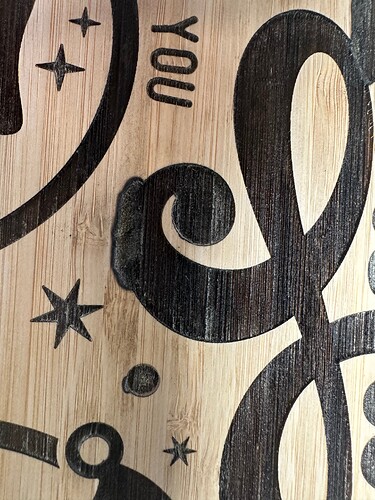

It definitely looks like an optical problem, because the blotches extend irregularly on all sides of the pattern’s proper location. That’s not the sort of thing you can get with a timing error or configuration mishap, although those are surely what OMTech will first propose. ![]()

I checked the Lens, it was tight and clean, plus I checked the mirrors and their alighment. All checked out OK. I will reach out to Omtech Tech and put in a trouble call. Thanks Ed.

I’m going to go out on a limb here because I cut a lot of bamboo.

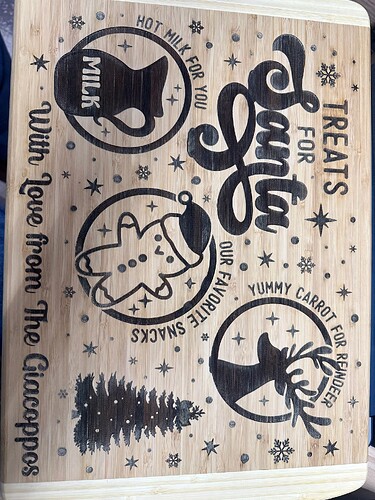

Your engraving is quite dark, almost charred, and you say you’re running a 60 watt, which leads me to believe you’re probably running pretty slowly to achieve that look on bamboo.

The areas you pointed out have all the tell tale signs of a prolonged burn. (prolonged could be even a second longer than normal)

I’m only basing my thoughts on the limited info you provided, but by visual inspection alone, I’m relatively confident that you’re going to find that it’s got nothing to do with your tube or your optics. I think your machine is fine.

I’m not being argumentative, but I’m inclined to disagree with others on this one, and I’ll explain why, and what my theory is… I think it’s worth a look either way. My gut instinct is to go in the complete opposite direction with your thought process. This isn’t a competition, I just know how I’ve seen this exact problem on this exact same material, and was able to remedy the situation. There is no guarantee it’ll be your solution, but it’s worth investigation.

I Have a 60 watt, a 120 watt, and a 600 watt RF, and I can pretty much duplicate your result on purpose by momentarily stalling the x axis by grabbing the belt.

The areas where you have the blotch are clearly a bit deeper, and slightly cratered. There is almost no situation I could think of where if your tube were failing, your power would substantially increase, or cause your beam to suddenly increase in diameter to what looks to be in the ball park of 5-6 mm.

If you look at your burnt spots with a magnifying lens, I believe you’ll see that the anomalies you’re experiencing are not the aggregated result of several passes, but rather one burn. I say this, because there is a rather heavy burn outside the boundaries of your vector.

In fact, were your beam spot to somehow increase in diameter upon leaving the tube, you’d actually get a tighter, smaller beam spot on the output of the lens. That’s the point of a beam expander.

I know the Omtech laser pretty well, and unless you opted for some sort of upgraded controller, it does not have a particularly huge memory buffer. That’s not an issue if your software is set up properly, and your computer is operating as it should.

I want to first ask this: are you sending the entire file to the controller before cutting, so that you could pull the USB cable completely once it starts, and the file would finish as expected? Or are you allowing the computer to stream the data as it cuts?

In almost 2 decades of working on Chinese lasers, CNC machines, and lathes for customers, I’ve seen many instances where the problem a customer was having suddenly appeared after working fine for a very long time. After exhaustive troubleshooting of the machine, we found that the problem stemmed from a bottleneck in the transfer of the file from the computer to the machine.

There are many things that can cause this.

Judging by the photos you posted, this is a larger piece, I’m guessing you’re using a decent line density, and the that file size is not exactly tiny.

I’m also noticing that the problem seems to manifest itself about 1/4 of the way into the file, and then starts happening again and again. I’ll bet this file takes a while to complete, and you didn’t keep your eyes glued to it the entire time. I know I don’t have the attention span to watch an entire engraving usually… lol

This would indicate to me that the initial buffer is running out, and the laser is either slowing momentarily, or stopping, to “catch up” with the new incoming information. That’s all it takes for the engraving to pop a little flame, and make a burn. Assist air will make it burn a nice little crater in a fraction of a second.

There are two ways you can test My theory. The first is to Hold the “Shift” key while you hit start, or to send the file, then hit start on the machine. This will send the entire file to the machine before cutting, which will eliminate all possibility of a bottleneck in the transfer disrupting the process. I’m willing to bet that it does not happen if you do this.

The other option, is to simply reduce the power so that the engraving is not black, and run the file the way you always do, but watch it the entire time… When and if a burn occurs, you’ll be able to see exactly what happened. Did the spot get brighter? Did the travel slow or stop? either way, the burnt area will have sharp contrast to the normally processed area, and it should be much more apparent what happened.

I may be wrong… If I am, be sure to say so, and I’ll own it. No one can guess correctly 100% of the time, and sometimes simply following the clues, and formulating a hypothesis doesn’t pan out. I’m fighting a problem Myself right now, which defies logic, and has left me baffled. But I’ll keep trying anything anyone suggests, because eventually, someone will be right!

Bamboo is fibrous and irregular. Unlike other materials where if you pulse the laser, it will create a pretty uniform hole, if bamboo hits the point of combustion, the burn follows the grain more or less, resulting is a remarkably different shape every time.

My theory is that if you can catch this happening real time, the anomaly will be accompanied by a flame, or glowing embers blowing from the charred area.

I’ve engraved a 24x 36" high resolution photo on My big machine, and experienced a similar issue. The file was way too big to fit in the controller’s on board memory, and USB kept bottle necking. I noticed when it happened, it’s like the machine momentarily slowed to a crawl, then resumed. My solution was to switch to an ethernet connection, and that solved the problem, as it allowed the software to stream the massive file progressively, but in a much more stable and reliable manner.

I always recommend a wired connection over wireless, and My #1 choice is always an ethernet connection.

Please be sure to report back whether to say it helped, or that you think I’m as worthless as a sack of rocks. (I can take it!) ![]()

I see what you did there. ![]()

A slowdown in the middle of engraving would definitely explain a lot of what’s going on, although torching a resinous / knotty / weird spot in the bamboo seems more likely.

Duplicating the problem on, say, cardboard would rule out most of the material issues.

AFAICT, Ruida controllers don’t have a “streaming” mode, although the command set includes direct XY motion commands with the laser turned on. GRBL controllers date back to the OG Arduino with essentially zero internal RAM that required streaming.

The only difference between Send and Start seems to be the file name: the latter sends the current layout as TEMPFILE, then runs it. Using my largest design, which is tiny compared to yours, LightBurn displays a transfer progress bargraph that fills & vanishes before the laser starts.

So I’d expect the bargraph to remain visible and partially filled until the entire file arrives in the controller, with the job starting after the whole thing arrives, but that’s based on my tiny files. Is that what happens with your giant files?

Standing by to have my misconceptions detonated …

That would be me, right beside you, full of rock salt. ![]()

OOoooohhhhhh!! I love when a couple of modest power players team up!

Ed & Steve, Thank you both for you input, I think I might have seen a small glimpse of what happened. I was doing another board with a different file and noticed where the laser was going back and forth in a small area, the air coming out of the lens made the embers glow more than they would have if there was no air. Like you all said, it could have been a bunch of small areas that either had some soft bamboo or resin and with the air blowing on it and it being a small area that the laser was focusing on, the air fanned the embers and created a small fire inside the board. and if anything, I’m the box of rocks, not the 2 of you. Let me know what you think, I don’t think there is any way to turn off the compressor but I did see you tube video of people adding a regulator to be able to adjust the air when you engraving verses when your cutting. Is this something you would suggest? Thank you again for you help and input.

That makes more sense than my notion of the tube going kaflooie and will be much easier to fix.

It might help to add a border on each side of the material to force the laser to scan across the entire width at a constant speed, without concentrating on any one area. You could put a hairline-wide border off the material on some cardboard where it won’t affect the result. That would slow your production, but should prevent the concentrated heating and give a more uniform engraving.

That works well and isn’t terribly complicated. Putting the air assist under automatic control increases the likelihood I’ll get it right:

- Engraving gets minimal flow with the layer’s

Airturned off - Cutting gets a high(er) flow with

Airturned on

The intent of the lower flow is to keep the fumes out of the nozzle and away from the lens, while not pushing the smoke down into the material you’re engraving.

My laser is probably pretty close to yours and this is how I did it:

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.