Hi friends, I have a carbon black problem after cutting that I supposed you’ve already had. I have Sculpfun S30 Ultra-33W and after cutting process it leaves carbon black/soot on the lateral area. What are the best ways that don’t steal a lot of time and to clean this carbon black area? Thank you in advance, have a nice day ![]()

First of all, you try to reduce it during cutting. The slower you cut, the more charring will appear. With my S30 U33W I never cut below 1000 mm/min. Adjust the number of passes accordingly. Turn on air assist, of course. I don’t have much charring at all. It’s visible sometimes, but generally, it’s negligible.

Some people sand their products to remove soot, some people use vinegar (I think). Some just clean with a dry piece of fabric.

A thin layer of masking tape or transfer tape will keep your material clean and add very little to the thickness of the burn required.

Could you please give me an example about that, brand etc? ![]()

When I will cut 6mm thickness of wood, I use 300mm/min and 3 passes, I will try to cut it with at least 1000mm/min and I need to increase number of passes of course.

LASERDARK.com sells monster sized rolls of masking tape. Easy to apply.

Plaque Masking Tape — Laser Dark

ROMARK has mdf boards that come with the masking material already applie.

Rowmark ColorShop® Wood (jpplus.com)

But I am talking about the carbon black on the lateral area because of the cutting ![]() That doesn’t seem what I am wondering.

That doesn’t seem what I am wondering.

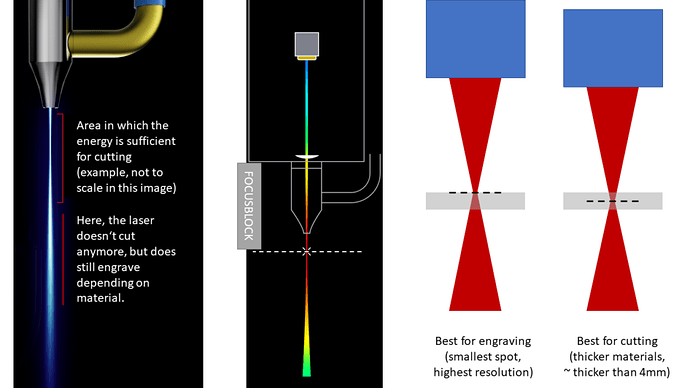

Cut faster and use more passes. Make sure your focus is set to the center of the cut depth. If you focused on the top surface of a 6mm thick pieces of wood, you are +/- 3mm out of focus by the time you cut through it.

Focus on the middle depth.

I arrange my focus like that, is that not okey? You told “If you focused on the top of surface of a 6mm thick pieces of wood…” So is what I am doing in here actually what you are talking about? What should I do while arranging my focus if that way is no true? Thank you in advance

Btw you were right, when I increase the speed and the number of passes while cutting, it went well and the carbon black/spot is not as much as before.Thanks a lot ![]()

That’s ok what you are doing. Though, if you have thick materials, it is sometimes beneficial to focus on the center layer of the material, not the top. That way, you get a more even burn and can cut thicker materials. See here:

(taken from here: Settings guide - Diode Laser Wiki)

Thank you very much it helped a lot, “The right one” was cutted with the settings of 800mm/min - %90 Power - 18 Number of passes(normally I even use less number of passes and less speed which always causes worse result than the “right one”) and “the left one” was cutted with the settings of 3000mm/min - %90 Power - 65 Number of passes, it seems well and using only a dry cloth to clean was enough. ![]()

Great to hear. What material are you using? 18 passes sounds a lot to me, not to talk about 65.

I usually cut 4 mm poplar plywood using the Ultra 33W with 1000 mm/min, 90%, 3 passes.

I’ve cut 6mm plywood, my laser machine is also 33W, but when I cut with the settings you told here the amount of charring is too much. I will use your settings with 4mm plywood and share the result again. And also could you please tell me the height of your focus helper? Thank you ![]()

I use the standard focus, it’s 40mm.