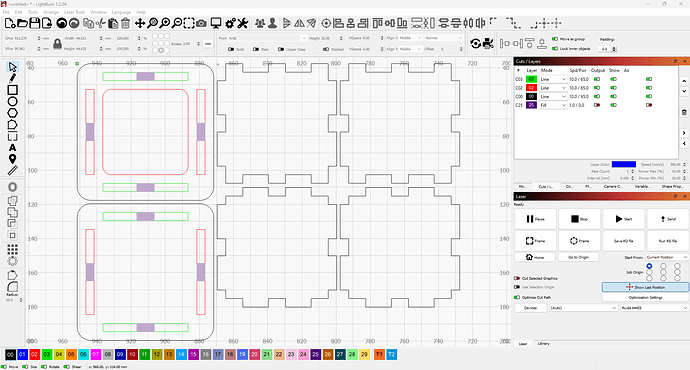

I’m currently working on a project creating boxes from 5mm extruded acrylic.

Pretty basic box, the sides fit together using finger joints and the lid and base have rectangular holes that line up with top of sides to slot in.

I’m experiencing a strange issue and can’t seem to figure out if its a software or hardware problem.

The rectangular slots on the both the lid and the base that are on the horizontal axis are being cut at a different size (near 1mm smaller) to the vertical ones although in light burn they are identical.

Can anyone explain why this may be happening depending on the way the shape is orientated?

As a workaround I have had to change the layer of the horizontal slots to include a kerf of 0.2 to cater for the difference in size.

Here’s a screenshot of the project.