Hi all.

New to lasers and looking for info from anyone with experience with the ACMER P2 33w Diode laser with regards to cutting paper.

I am looking for guidance with regards to Settings for Power and Speeds ( which I assume will be similar for all 30W Diode lasers?

Any help would be greatly appreciated. Thanks ![]()

The trick to cutting paper with a (any) laser is finding the right balance between speed and power. Paper is not quite as uncomplicated as, for example, wood, because it can burn faster.

I have done some tests that involve not burning through the paper, it is actually even harder ![]() , but in return you have found your parameters so close to the limit, that it is easy to find the last % that is missing to cut without marks and fire.

, but in return you have found your parameters so close to the limit, that it is easy to find the last % that is missing to cut without marks and fire.

I reduce the air a lot when I cut paper and use relatively high speeds.

Good advice, keep an extra eye on the laser when you cut/engrave paper and have a fire blanket ready.

Thanks Bernd, much appreciated.

I think I have it dialed in!!! in as much as it cuts cleanly without any signs of burning🙏

The only thing left to try is multiple layers, ie several sheets at one go but to be honest that is not my priority as i am happy to cut as is!!!

For info i found that 2400mm/min at 63% seems ideal at the moment and a really good jumping of point for future tests ![]()

@bernd.dk is correct in this assessment. However, it applies to all machining operations. If it’s additive, such as 3d printer, or subtractive such as a milling machine, drilling or lasing, it still has certain speeds/feeds that are used.

Although we relate speed to how fast the head is moving, most of machining uses this as spindle speed, but it’s the cutters or engravers laser power. Feeds are the part we usually related to how fast we’re feeding material. Of course these is the combined speed. We can move the head around the material, the material around the head or a combination of both.

With a piece of steel or other types of known materials, you can compute feeds/speeds that work best with your material. With cutters/3d printers have a speed and feed that works best for certain materials and how many flutes there are on the cutting head. I use a calculator for my small milling machines.

The issue comes up that with a laser, is they too many parameters vary. Even the same power has variations in beam quality and lens lens determine power. variations anywhere from the tube to the work piece can vary, which exacerbates the variations in materials that we see when we use a laser, especially on most natural products.

This occurs with any type of machining. Many speeds (power) and feeds (speed) will do the damage you want to the material, but a very small range of speeds/feeds will perform the best.

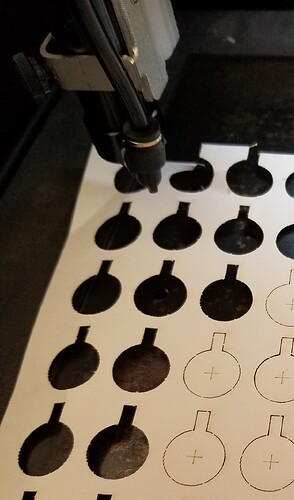

I cut alignment targets out of watercolor paper since it’s thick enough to handle easily. Perforation mode is on so they tend to stay in place until I need them. Note I have center cross hairs and a tab so I can tell right side up… or however you put them into your machine.

Follow @bernd.dk advice and dial in the speed/feed for your machine.

![]()

Hi Jack

On the parts I am cutting out I have left one leg on opposite sides of a star uncut completely so they have to be manually cut or torn. I am guessing using perforation mode on those parts would make it much more easy to part them from the sheet!! Just have to go and find out how to use it in lightburn and on my laser now ![]()

Thanks for the input.

Rgds

I made a run of raffle tickets for a fund raiser. Heavy paper works a lot better than light paper. Glossy paper does not work well. Perferation mode is very nice. I ran into difficulty when I tried to cut more than 3 sheets at a time.

10w diode

Just stack the paper layers and put a piece of glass on top. The glass will also keep the paper from warping. Since the laser beam just goes through the glass, there is nearly no loss in power.

That makes a lot of sense, great idea Melvin ![]()

Thanks