I would like ask how in settings of layers setup delay for laser fire (burn-in) in relationship to air assist.

I have noticed on my laser that when laser starts at same time as air-assist, delay caused by pump start / building of pressure leads to burn marks on places where laser starting cutting.

Not sure if this will help. On my OMTECH the air comes on when I start the cut. So maybe if you set the Home position to the Right Rear. And do most cutting at the other end of the bed. Maybe by the time the head gets to the start of the cut, the pressure may be high enough. I think there is a setting for the speed the head travels when not cutting. Maybe slow it down also.

Or you could get a external compressor with a tank. Works great.

This works and no need to slow down the traverse rate. Set a “Retract” (Macro) position for manually moving it out of the way. Set a “Finish” position for when the job ends. They cam be the same position if you want.

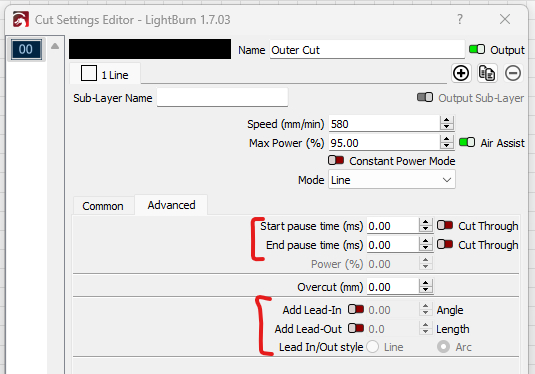

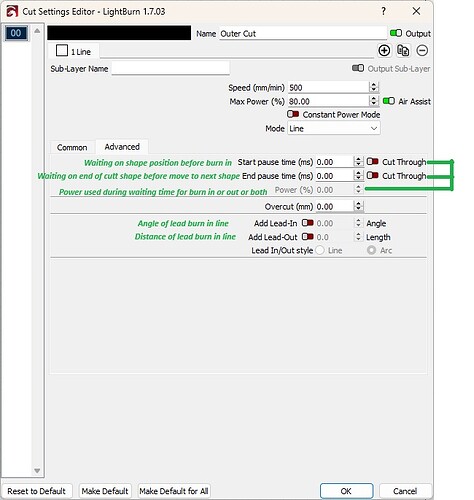

I’m not fully familiar with advanced settings in layer, but like the lower part (I was using some software for oxygen cutter many years ago - there it was automatic or you could choose side manually) - how Lightburn will recognize it should be inside or outside of cut shape? - I’m not so much familiar with it yet.

Upper could be settings for some delay, I will try them later today.

With traveling / home position it’s a good tip I will check also.

Me neither, but the same thing has happened to me. In plasma cutting machines I understand these definitions. How it works on the laser machine just testing.

I know this topic has already been discussed elsewhere on the forum. Search because you should find more information.

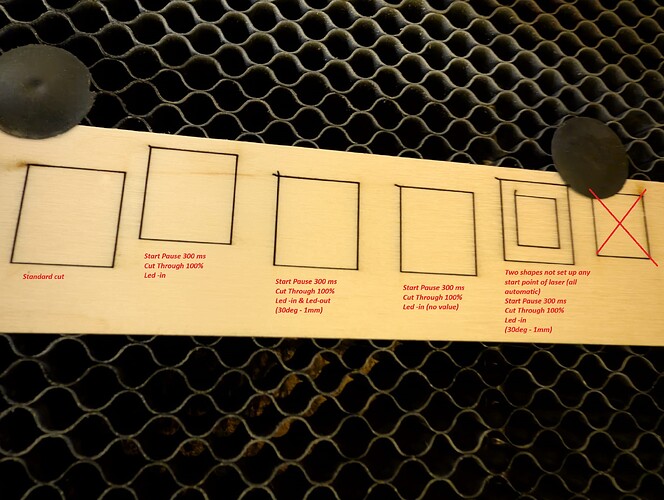

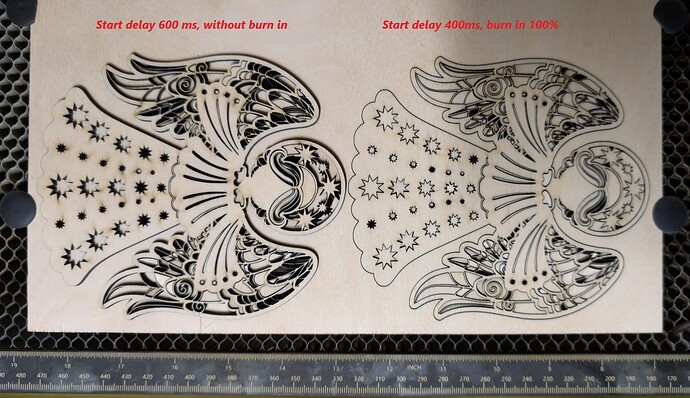

Ok. I did some quick tests.

I found that the most important parameter in the advanced settings is

“Initial Pause Time” - it mainly helps to avoid the burn/smoke area around the burn-in while the air assist is already working (if checked).

I have prepared a description of the settings after the test, I hope it helps.

(I tried to find it in the LightBurn online manual - but they are not explained).

In my opinion, if we combine the initial pause and cut time, we get the same thing as with an oxy torch - preheating and starting the cut - which is the best solution.

I will work a bit more on the delay time later, but so far the results are a very good improvement compared to the standard settings.

Test examples and settings

Cutting result

Acc. external compressor is good idea, but im my case I don’t have space for it.

I have ordered dual air pump from Atomstack F60 which has 60L flow.

I’m hoping this will improve my cut in additional.

So far I have tuned my Sculpfun by lowering nozzle to preform better “blowing-out”.

Thank you for your feedback. That’s nice results!

I don’t think so. If it kind of mine it will take 1 to 1.5 seconds to full power.

I don’t know if it is acceptable for you, but if you mask the wood with tape i am convinced there is any fumes on it.

I have found this helps.

Since the air assist starts at the beginning of the “free” movement and then stops and waits at the beginning of the shape, this wait seems to be enough time to stabilize the blower flow.

I will check the delay settings and if all goes well I expect the pump to arrive next week, I can post an update once it is installed.

I think the tape may be ok with single shapes, usually as you have seen I do more elements at the same time.

Because things like these I mentioned “if it is acceptable”, tape is not suitable for all occasions.

As you mentioned exactly it all depends on the needs, but as earlier - very good suggestion/solution.

My main goal was to avoid any special operations like macro or others,

I just want to start the machine and receive the finished item.

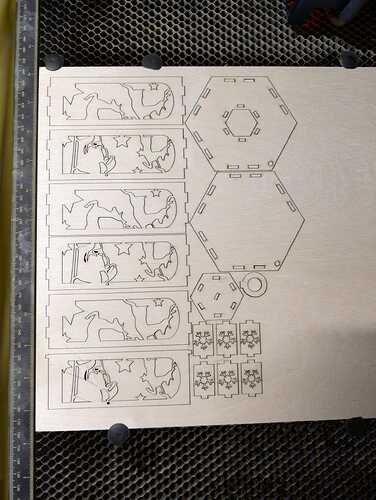

I just started the process of trying different parameters and their effect on the cutting efficiency.

I am not sure if my tests/trials can be helpful for someone else with their machine settings, but I myself spent several days on this topic on YT and the Internet, without finding any correct explanations.

I did more tests on complicated shapes, the pump (30L standard unit) starts up under 1 second in my setup.

I will re-make test after new hardware arrivals.

Isn’t that what we all want? Of course I understand that, even me… ![]()

I’ve been through something similar and I still do.

The biggest problem is that each case is different, and the settings on one machine rarely match another machine, even with the same make and model. Some adjustments always need to be made.

Obviously, having the experience of someone who has been through the same thing is a big help. That’s why by sharing experiences, we’re all learning.

Now I have a question, during the delay is the laser head moving or stationary?

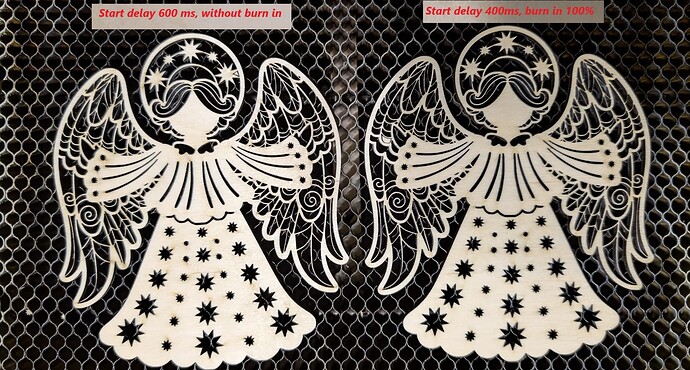

Let me tell you something else, those lines that are so thin and so well cut are amazing. Congratulations!!!

Thank you.

Waiting time is stationary, on start point of cut/shape.

Meanwhile, when I looked at one of the images you posted earlier, I noticed that you mentioned exactly that.

Thank you!

This weekend I tested the response time of my air assist it’s 0.8 secs no 1 to 1.5 as I said before. ![]()

!0w cuts like a 5w, no?

Mike, I’m sorry. I’m kind of lost here… Cab you enlighten me?

After a few days of rest and out of here (health problems) it would be expect a better understanding, but nah… I still have the same difficulties as before. Age don’t forgive!!! ![]()

What I meant was the 10w Sculpfun cuts a fine line like everyone else’s 5w laser. The Sculpfun lasers are notorious for having a fine dot and long depth of focus (DOF). I rarely use the rotary on the S30 and SF-A9 for this reason. It engraves over an arc pretty well.

Sorry for the sales pitch. One of my flaws of Age!

This is done by Sculpfun S30 Ultra 22W.

As I mentioned earlier, I received an Airpump from Atomstack, but it is powered by 12V, not 24V like my laser. Once I determine compatibility, I will post about the differences from the standard airpump.