Hi all, any suggestions gratefully received.

I have an Neje Master 2s Max, have managed at last to get set on lightburn with help of reading forum posts, now run updated neje device profiles, for 2s plus and enlarged areas.

Downloaded correct drivers as per post and all working ok, however, same as before, the laser engraved perfectly, no issues or complaints, but, it won’t cut.

Have read posts, watched video’s and they all seem to imply the 30w laser head can cut, 5mm ply on second pass, at 80%.

I have tried and tried in settings, adjusted speed, power etc. But can’t get mine to cut 3mm ply even with 7 passes.

I want to make boxes, earrings, puzzles etc. help!

On neje program, no longer installed, if I put power to 100% you could hear a difference in the laser noise and fan running, on lightburn it seems to be held back, so 5 passes at 80% will get me 2mm in and scorch the surrounding area!

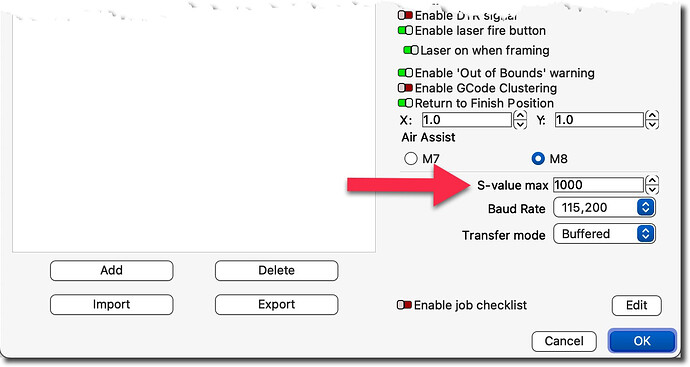

Can you tell us what your $30 value is?

Also know as S-value Max and can be found in Device settings.

Hi, S value is set 1000 as per your image, only ghong different on my screen is laser on when framing and enable laser fire button are off.

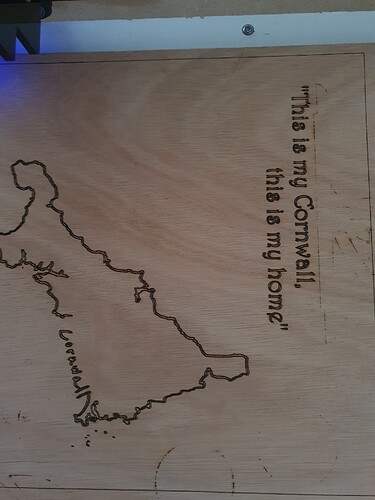

Heres a couple of pictures, first is engrave on solid oak, fine as I need it, second is front of a lantern box cut, 6 passes on 80%, 3mm ply, next is rear of same.

Does this show the order you cut these?

Engraved first, then cut front, then cut rear.

Right?

Engrave was different job, second picture is cut on that face, last picture is back of that sheet to show how it not gone through, I’m totally disheartened by it as everyone else is going 2 or 3 passes and I’m getting nowhere with 5 or 6.

Might be a dumb question. Just trying to cover all the bases.

Did you clean your lens? Burning wood can create a lot of soot and smoke.

Have cleaned lense, although it’s a new machine, I have a large fan blowing across work to blow smoke away until air assist bits turn up, I have just ordered a new focus lense just incase too. I will try loading a video, focus looks fine to me and engraving like a fine marker pen at 600mm/m at 75%

Are you using Air Assist at all I just changed from an older style double aquarium pump to a line from my workshop compressor using between 2-8 PSI on 3mm Ply/MDF and with 1 pass and little or no blackening edges…

Have large fan blowing across, can see debris and smoke getting blown away, have tried air line with thin pipe at 10psi and makes no difference, have air assist kit on way but videos show non air assist doing 5mm in 2 passes.

What speed are you running? Pay particular attention to focus as well. You should be able to do it. I can cut 1/8" Baltic Birch with a 7W diode laser, though it takes some time. They’re decent for engraving but not really built for cutting in my opinion. I upgraded to an 80W CO2 and it made a HUGE difference in time and quality.

Speed is 200mm/m, anything over 80% just burns surrounding area as it goes. Pictures show how nice it is for engraving so confident about focus, unless lense has scratch and is distorting beam, tried at different focal heights and all have same results, almost like power held back. Don’t have thw budget to go to 80w co2 erc.

Just to get back to the start, you have confirmed your S value is 1000 can you also make sure that your $30 value is the same

Yep, same, I don’t know if it’s lightburn holding power back or issues with laser, but it engraved so nice, free trial running out and if I can’t sort I can’t justify the money incase it’s not the laser.

Just to eliminate other issues. can you confirm that your file ‘cuts’ as you would expect using the Neje software ?

I will try again with neje file tomorrow, just incase things have changed, but, it was visibly and audibly different when ramping power up.

But as most are aware, Neje nowhere near the program that lightburn is! Not wanting to import my gcodes or anything other than it’s own library.

We can test this because we know that S value max = 1000

If you’d like to confirm, please open a new blank project and open the Console window,

connect to your laser and click the switch on the right hand side of the Console Window to the ‘Show all’ position

Then engrave one line along the x or y axis, from somewhere near the origin in a straight line about 10mm long.

Then run that small job.

When that job is done, copy everything out of the Console window from the end of your test line back to the beginning. If your project is small enough we should be able to see everything we need to confirm in the last 10 lines or so.

Sounds about right. I drop to about ~20 mm/s on my CO2 to cut wood. 3.3mm/s seems reasonable. It usually took me 8 passes to cut 1/16 (I just looked, it wasn’t 1/8") with my diode laser, just too slow for me to be useful but it’s not a hobby for me, it’s been bringing in quite a bit of money. My diode is attached to my CAMaster Stinger III and it was driving me nuts to watch a $30K machine running an hour long pass with the laser. ![]() I’m saving time and wear and tear on an expensive machine with the new CO2.

I’m saving time and wear and tear on an expensive machine with the new CO2.

Here’s a fun test between the two to show you the power difference. Item 1 is a 7W Jtech @ 95% power. Item 2 is my CO2 80W @ 20% power.

How long since you cleaned all the mirrors and lense