I cut/engrave Acrylic most of the time.

I used the origional egg crate for a while but got VERY tired of the marks/melts on the back of everything I cut.

I moved on to 1" x 2" magnets from Home Depot. They work … mostly.

Sometimes I still get a melt on the back of a project. I appears to be a bounce from the Stainless Steel table. If I lower the power then the piece does not get cut through.

If I turn the magnets up to tall then it solves the bounce (?) but if pieces fall out then they can get cut by the beam.

So I made a 10" square 1/4 acrylic with rows of .125 holes spaced 2" apart. Covered it with Reynolds wrap dull side. And placed 2" rivets in the holes. Works great and I have lots of the needed support.

BUT I still get a beam bounce more often than not. So I painted the tin foil BBQ paint Black. That was REALLY Wrong!!! Catches FIRE!!!.

So I would like any other Idea of what to use as a standoff for cutting Acrylic.

What do you guys use??

Thanks for any suggestions

I mainly use my bar / knife table as much as possible to reduce the reflection. The spacing between each bar is 2 inches. I also run the speed and power settings as close to ideal as possible. One reason for proper speed and power is to get a glass clear edge, and a second reason is to reduce the amount of reflection.

Air assist and really good fume extraction combined with the above also helps to lessen the effects of reflection.

MY table is SS with small slits for air. It is about 24 x 36.

Still havin reflection issues with acrylic! @#$%^! The 2" rivets is still the best thing. But I still get a LOT of refection burns on the back side of the project. There must be something out there we can use. Has anyone found anything that works?? How about a piece of brass? Holes with the rivets maybe…

GREAT IDEA!! But what is the nail stuck into? Mabe Fire proof Wallboard??

CNC drilled holes in an 18 mm multiplex plate (drill holes slightly smaller than the nail)

then cut everything to size with a hammer.

Poured a layer over the plywood with two inexpensive components of glue

Greetings Sjaak

I use magnets to raise the items 1 cm or 15 mm depending what I need.

Works well.

Thanks, I just went to HD and got 2 inch Magnets They seem to work well standing up on the SS bed…so far…

Thanks again

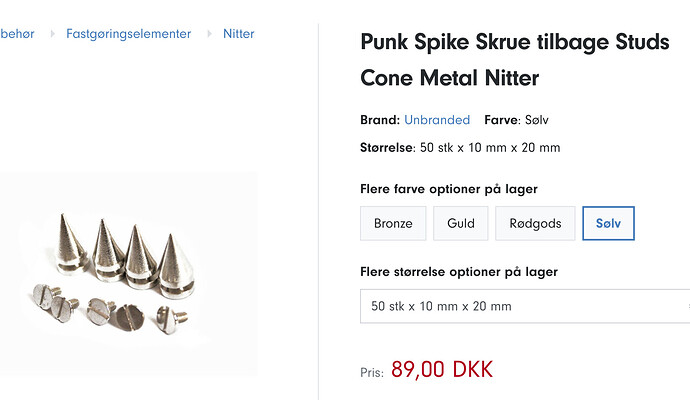

I have always used “punker spikes”, and for my new machine I have ordered 60 pcs. Ø10x20 high which has threads at the bottom. I mount them with Ø10 round magnets with holes and countersinks, they fit perfectly on a 2mm steel plate which is very easy to clean. In my K40n I use spikes with a perforated plate, it has the advantage that the smoke comes away even better. I have very little trouble with fire tracks or reflections from below.

Thanks for the info… BUT I do not know what a punker spike is. They sound great! Any chance you could post an image of your creation? I would really like to see it. I am using the 2-inch magnets today and that seems ok, but my beam hit one of them and !@#$%. I need to pay more attention to their locations.

…probably a bit of a translation error, a punker is referred to as punk here in DK.

Picture of my K40 punk system

please do not comment on what it looks like, at least it does not reflect !!!

Hehe ‘punk’ rock died back in the ‘80’s, but I remember the spikes

Thanks every one great ideas. I ended up using the magnets. They have not caused any issues …with reflection yet… and then my controller has failed. New one arrives today.

Merry Christmas Everyone Stay safe