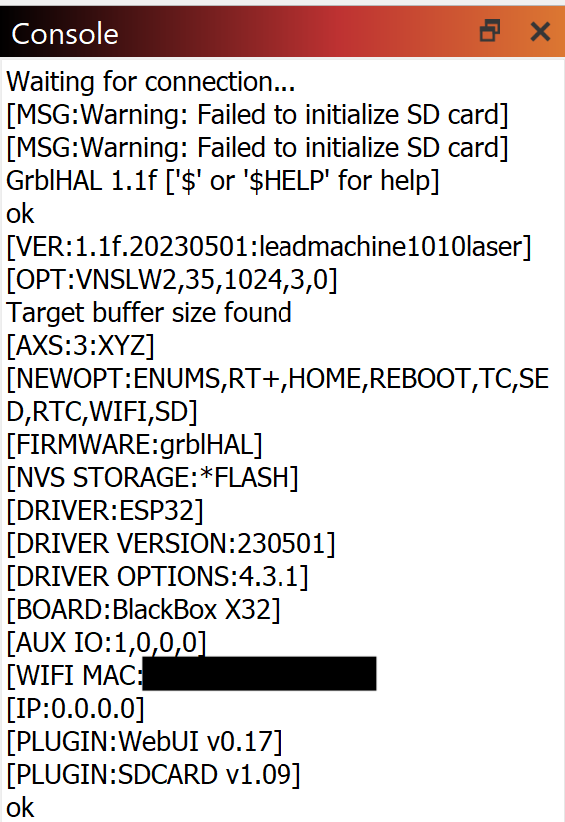

Hi All!

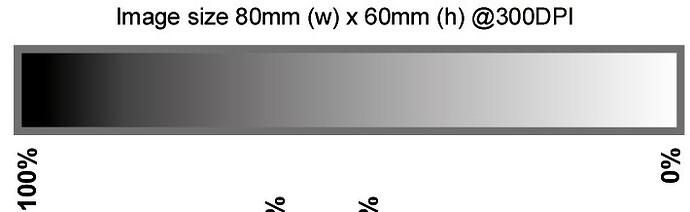

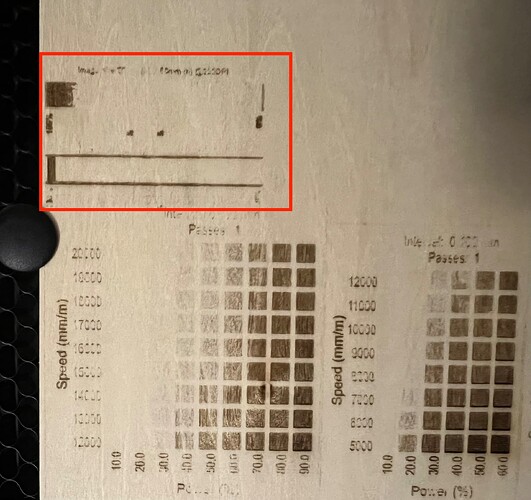

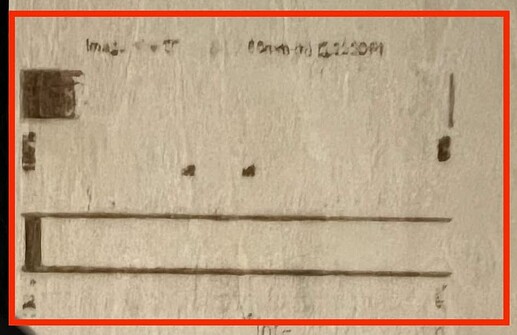

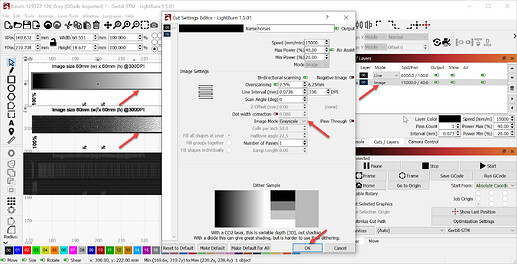

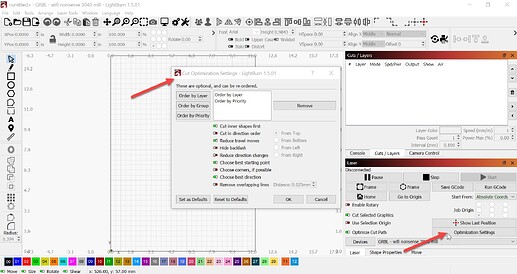

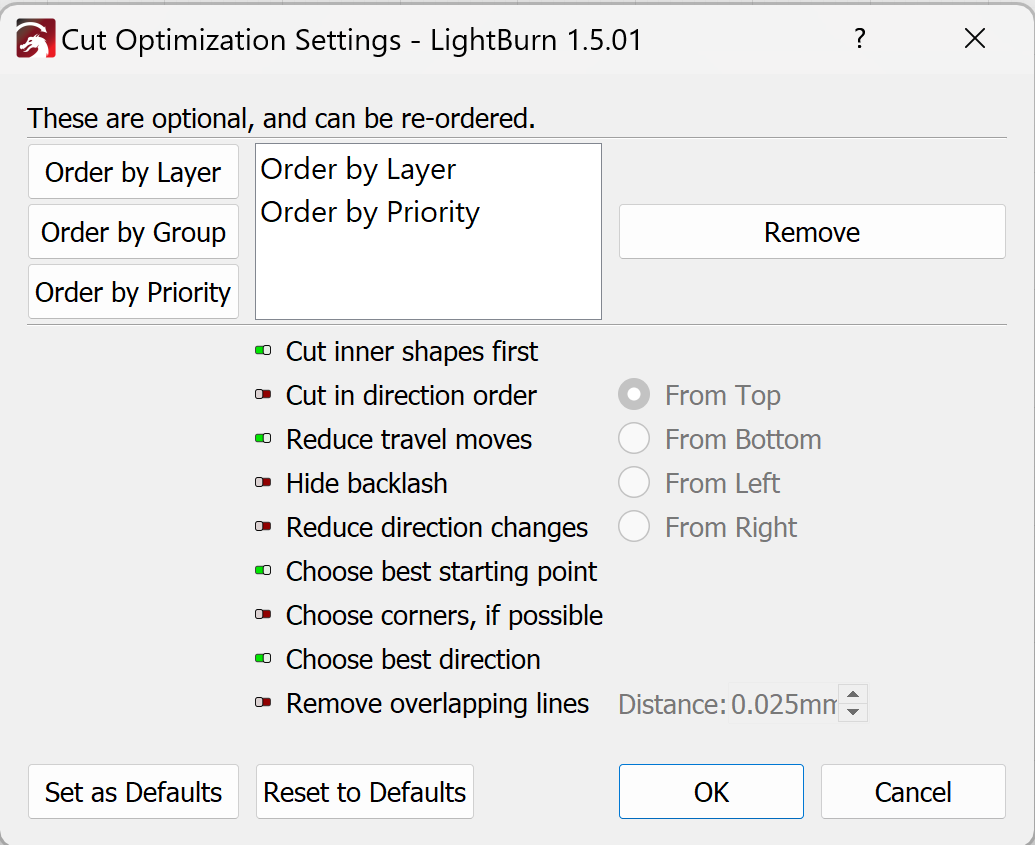

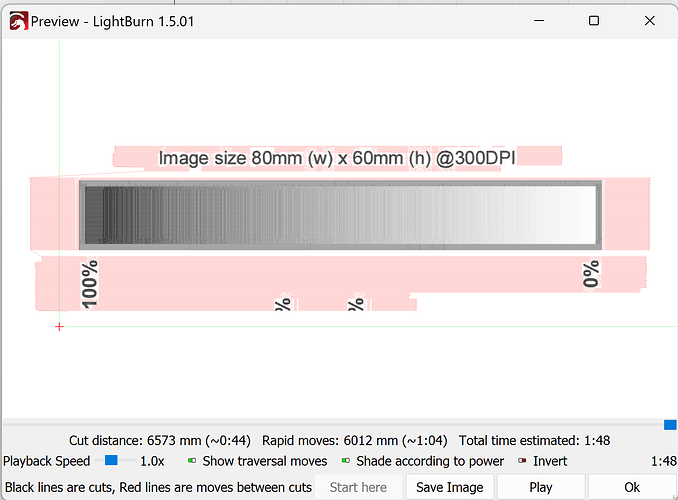

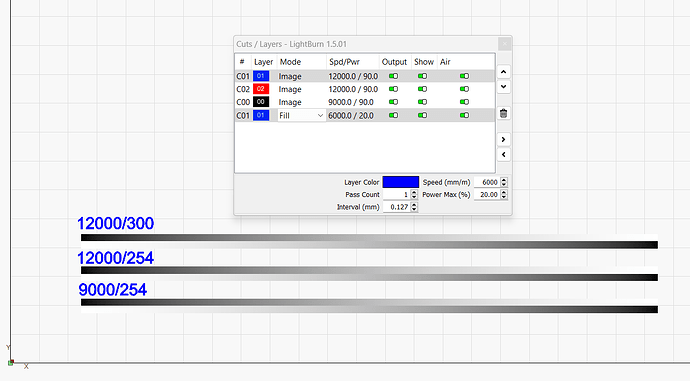

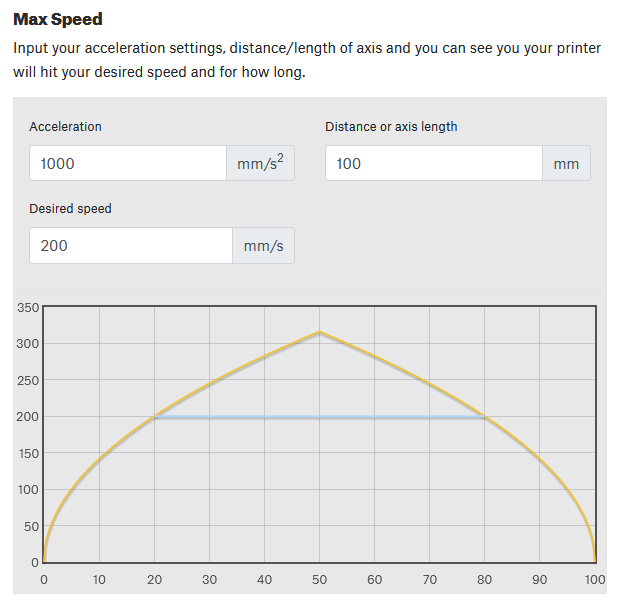

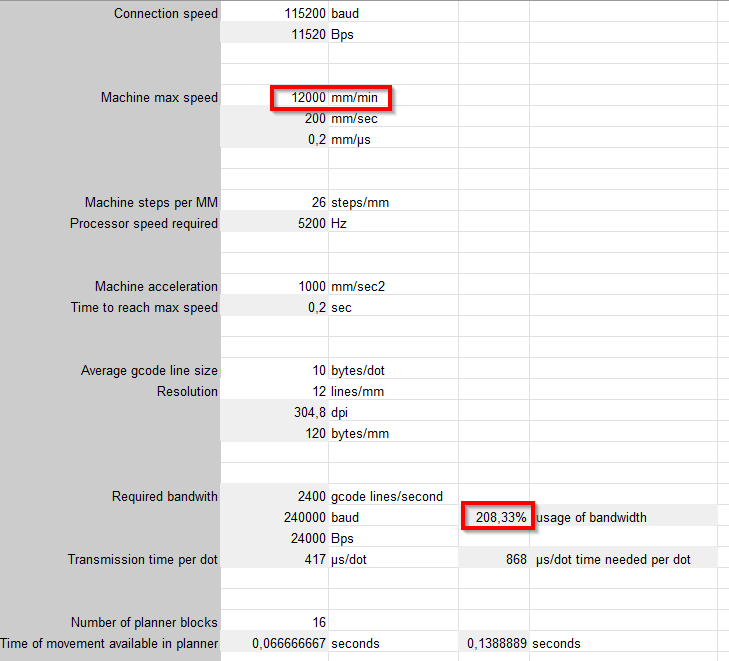

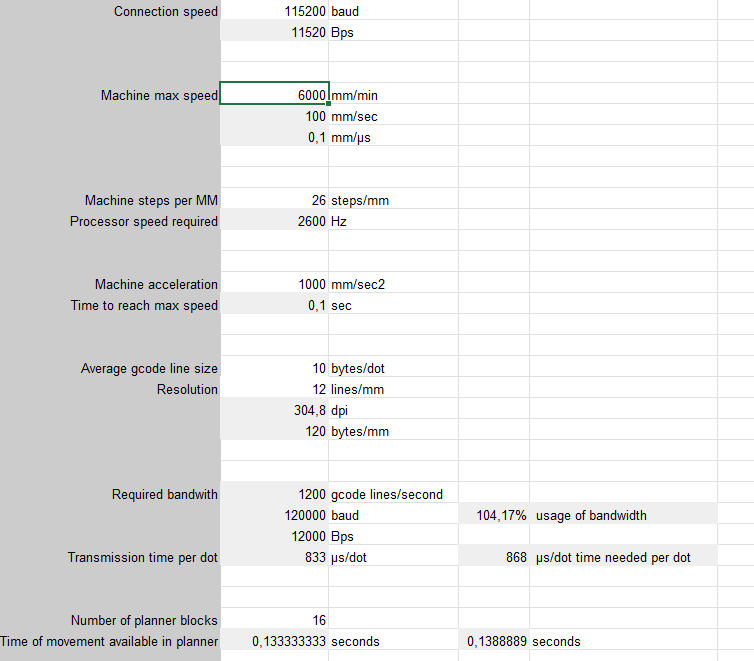

I have a Openbuilds Custom CNC that uses X32 blackbox controller running GRBL HAL (Build 20230501). My issue is that the machine stutters (likely taking pauses with every change in power value) leading to engraving being super slow. A 2 min engraving file (based on preview in Lightburn) takes well over 10min on the machine with speed no where close to my engraving speed of 12000mm/min. Running Grayscale image more of Jarvis - no constant engraving speed…the laser seems to be firing up correctly but engraving doesnt take place. When I run material test setting, I can get engraving even at 20000mm/min speeds. unsure what is going on but any help troubleshooting this would be appreciated

Here are my GRBL settings:

$0=10.0 ; Step pulse time, microseconds

$1=15000 ; Step idle delay, milliseconds

$2=0 ; Step pulse invert, mask

$3=4 ; Step direction invert, mask

$4=0 ; Invert step enable pin, boolean

$5=7 ; Invert limit pins, boolean/mask

$6=1 ; Invert probe pin, boolean

$8=0 ; Ganged axes direction invert as bitfield

$9=1 ; PWM Spindle as bitfield where setting bit 0 enables the rest

$10=1 ; Status report options, mask

$11=0.010 ; Junction deviation, millimeters

$12=0.002 ; Arc tolerance, millimeters

$13=0 ; Report in inches, boolean

$14=0 ; Limit pins invert, mask

$15=0 ; Coolant pins invert, mask

$16=0 ; Spindle pins invert, mask

$17=0 ; Control pins pullup disable, mask

$18=0 ; Limit pins pullup disable, mask

$19=0 ; Probe pin pullup disable, boolean

$20=0 ; Soft limits enable, boolean

$21=1 ; Hard limits enable, boolean

$22=1 ; Homing cycle enable, boolean (Grbl) / mask (GrblHAL)

$23=3 ; Homing direction invert, mask

$24=100.0 ; Homing locate feed rate, mm/min

$25=1000.0 ; Homing search seek rate, mm/min

$26=250 ; Homing switch debounce delay, milliseconds

$27=5.000 ; Homing switch pull-off distance, millimeters

$28=0.100 ; G73 retract distance, in mm

$29=5.0 ; Step pulse delay (ms)

$30=1000.000 ; Maximum spindle speed, RPM

$31=0.000 ; Minimum spindle speed, RPM

$32=1 ; Laser-mode enable, boolean

$33=5000.0 ; Spindle PWM frequency

$34=0.0 ; Spindle off Value

$35=0.0 ; Spindle min value

$36=100.0 ; Spindle max value

$37=0 ; Stepper deenergize mask

$39=1 ; Enable printable realtime command characters, boolean

$40=0 ; Apply soft limits for jog commands, boolean

$43=1 ; Homing passes

$44=4 ; Homing cycle 1

$45=3 ; Homing cycle 2

$46=0 ; Homing cycle 3

$62=0 ; Sleep Enable

$$384=0 ; unknown

$396=30 ; WebUI timeout in minutes

$397=0 ; WebUI auto report interval in milliseconds

$398=35 ; Planner buffer blocks

$481=0 ; Autoreport interval in ms

$63=2 ; Feed Hold Actions

$64=0 ; Force Init Alarm

$65=0 ; Require homing sequence to be executed at startup

$70=7 ; Network Services

$73=1 ; Wifi Mode

$74= ; Wifi network SSID

$75= ; Wifi network PSK

$100=26.667 ; X-axis steps per millimeter

$101=26.667 ; Y-axis steps per millimeter

$102=200.000 ; Z-axis steps per millimeter

$110=38000.000 ; X-axis maximum rate, mm/min

$111=38000.000 ; Y-axis maximum rate, mm/min

$112=3000.000 ; Z-axis maximum rate, mm/min

$120=1000.000 ; X-axis acceleration, mm/sec^2

$121=1000.000 ; Y-axis acceleration, mm/sec^2

$122=150.000 ; Z-axis acceleration, mm/sec^2

$130=630.000 ; X-axis maximum travel, millimeters

$131=1280.000 ; Y-axis maximum travel, millimeters

$132=100.000 ; Z-axis maximum travel, millimeters

$320=grblHAL ; Hostname, max: 64

$325=23 ; Telnet port

$326=80 ; HTTP port

$327=81 ; Websocket port

$341=0 ; Tool Change Mode

$342=30.0 ; Tool Change probing distance

$343=25.0 ; Tool Change Locate Feed rate

$344=200.0 ; Tool Change Search Seek rate

$345=200.0 ; Tool Change Probe Pull Off rate

$346=1 ; Restore position after M6 as boolean

$370=0 ; Invert I/O Port Inputs (mask)

$384=0 ; Disable G92 Persistence

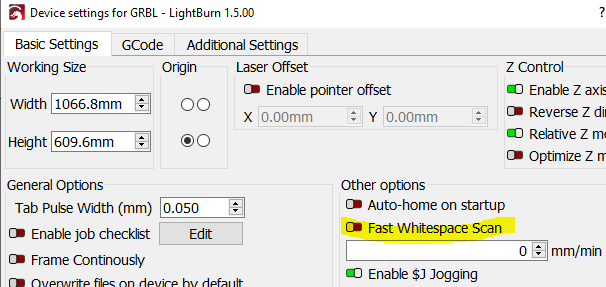

Also, have set S value max of 1000 in Lightburn

Please help!