I was just thinking aloud. I wouldn’t know how it would work. In Fusion 360, I believe that you can snap text (Vectors) to objects and have the text conform to the shape. I wouldn’t know how it would work either in this scenario.

Here is the laser: Laser | Sienci Labs

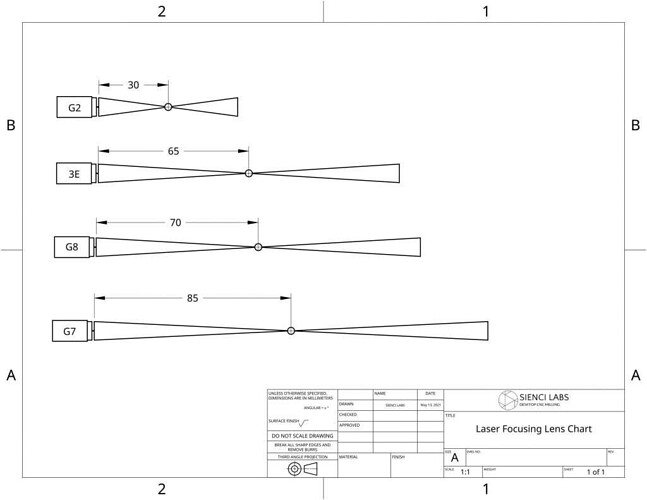

Here are the lens offerings - It comes with the G2. I have the 3 Element and the G8 on order.

Ah, yes, if I did it the way you suggested. Is it true, at least in LB, that anytime Z is initialized it turns the laser off?

I am imagining that you focus the laser and set the Z height, then start the G code on the 3D model tool path. It moves the gantry, following the contours of the 3D model and only burn in the vectors (in this case, Topo lines, roads, hiking trails, etc) while maintaining the original set Z height to preserve the focal point (length).

I am not sure what this means?

Please excuse my ignorance. I am just getting started in the hobby and most likely biting off more than I can chew. I’m mechanically inclined and have a computer hardware background. Lacking developer skills but still learning Arduino, etc. So, I have the skill sets for this and there is plenty of information out there. It’s just timing to get and absorb it.

OK, my idea behind this is that my wife and I love to hike, camp, and over land. We have a friend who is a hard-core hiker and mountain climber. He’s climbed some pretty gnarly peaks and plans on doing more. I would love to show his base camps, climbing paths, along with other cool landscape markings, etc. I want to make those 3D models for all of us as commemorative pieces and have a ton of fun and learn along the way.

Just looking at the easiest way to do this.

Again, thank you!

![]() Just trying to get a jump start on my education before I get it.

Just trying to get a jump start on my education before I get it.