I’d suggest you pass on the K40 types and go with something like I suggested considering your response of it’s intended use.

If you get on OMTech mailing list they will notify you on sales or specials. I used them because of the horror stories of people that have paid less and ended up waiting longer and not getting the machine they thought they ordered.

Most of these companies are in China or based there, so you sometimes have to deal with that and they are translating…

My laser came and worked fine. So I never had a reason to contact OMTech for any issues. Most of the people that have blogged it, claim they respond pretty well, compared to some companies that people never get a response from.

Some have gotten great deals, others have had it dropped off in San Fransisco when they live in the Midwest and had to hire an attorney out there to deal with customs and getting it shipped to their home…

Most of these will not have a ‘square’ work area. Mine is a 5030 which is close to 20"x12".

If you are just going for engraving, thickness is moot. If you wish to engrave and cut the object out (typical) then the thickness.

Choosing the ‘right’ power is one of the problem areas with lasers. What power is dependent on thickness you wish to cut along with what speed it occurs.

I purchased mine entirely for educational purposes, for me to learn how these work.

Having access to a cnc machine, I purchased a CNC3018 and later a laser and Lightburn. This gives some education on how they work and since you had one, I think I can image where you are at… but it’s an assumption…

You read about percentage power and speed control… Keep in mind that power is actually power/time and the when it lases, it does so at 100%. If you set the ‘power’ at 50% then it will lase 100% power for half the time.

DC excited lasers co2 use high voltage to excite the nitrogen. The main issue here is that most won’t lase below 10% power level and it takes times for it to lase, unlike an led.

What I’m driving at, is if you want delicate engravings look more at the lower power than the higher power. You have more ‘power’ control at the low end of the power rage of the tube.

If you have a 100W laser and can get 10% power, you have about 10W, if you have a 50W you get 5W. Generally engraving does not take high power. As I stated earlier, the 100W will lase at 100W and do 100W of damage to the material when it’s lasing…

Higher power is usually used for cutting purposes… go more this way if you are mostly cutting materials.

Take you time and listen to the others that have followed your path.

There is definitely more ‘fiddling’ with tubes, mirrors and lenses… it also increases the flexibility of what you can do…

Mine’s had a change or two… Good luck

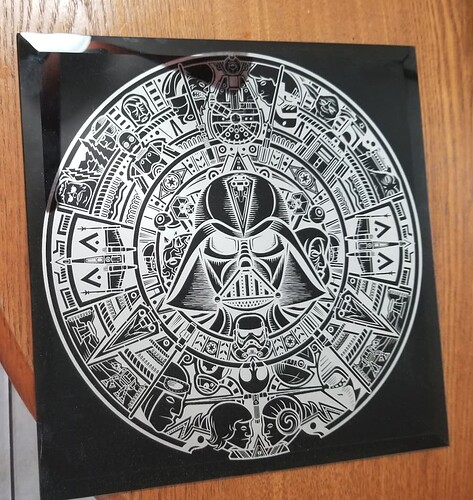

I like doing these… etch off the back and paint it black…