So you are telling him that a ‘mechanical’ item that has to physically move and arcs most of the time is more dependable than solid state equipment.?

I think there is more than sufficient data to show the mechanical relay is comparably a piece of junk up against a ssr as far as dependability, holding current and heat. It doesn’t generate it’s own emf field on energizing or generate a reverse pulse when the field collapses. The cost of a mechanical relay is reaching or exceeding that of a ssr. Add to that ssr are pretty idiot proof.

They have no problem switching the in the 50 - 60 Hz range, there is no inductive issue with the mains. I run motors on my laser with one, no issues there either.

I’ve been working with them since the early 80’s and can recall only one failure of a ssr when the equipment it was running shorted out and put a couple hundred amps across the switch, it became the fuse and blew… I’m sure they fail, but there is no comparison to mechanical relays.

I have replace an uncountable number of mechanical relays. An surprising amount of them had mechanical failures that caused to ‘stick’ in the energized position, resulting in at least one fire. On a transmitter on top of a mountain I used to maintain, one of the relay coils shorted and it started a fire inside the transmitter… It was a 4 hour drive just to get there, wish that would have had an ssr in it.

A ssr switches on at the mains zero voltage level (read ‘no current draw’), unlike the random connection nature of a relay. It is much more easy on the equipment to have power enabled at a zero voltage/current load on the mains.

They can take a heat sink for the higher current loads, but they only draw about 20mA about 1/10 as much as a coil and no emf or back emf fields.

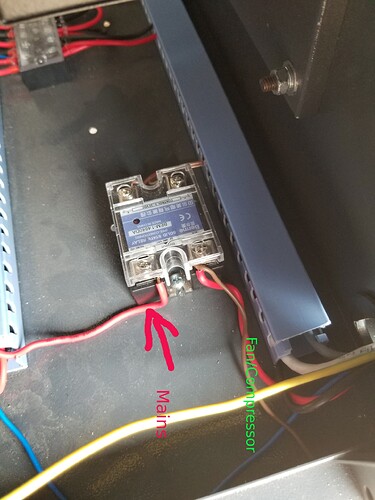

I use them anywhere I can, haven’t lost one in over 20 years. This has been in my machine since I received it, don’t expect it to fail anytime soon either. Ran both exhaust fan and supplied compressor, hence no heat sink, just mounted on the chassis.

Do you actually have a lps on yours? I thought that those rf lasers was a ‘all in one’ box ?

I had thought the idea was to power down the whole machine… Your suggestion assumes you keep your 28v supply on all the time. That’s why I noted the requirement of a full time supply with an ssr, same with a relay except it’s going to draw more power.

I don’t know if their 240 is like our 240, comprised of a neutral and two 120 legs.

The beauty of being free, you can choose what you wish…