A grayscale bitmap file should work fine too, you would just need to set the Min and Max power values appropriately.

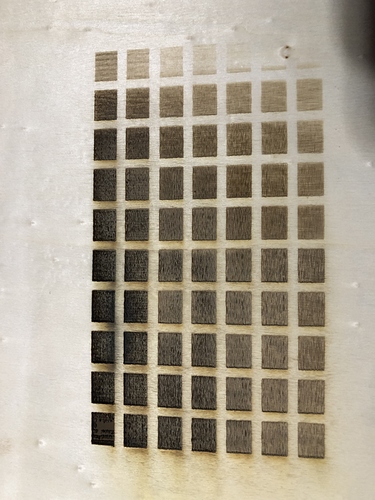

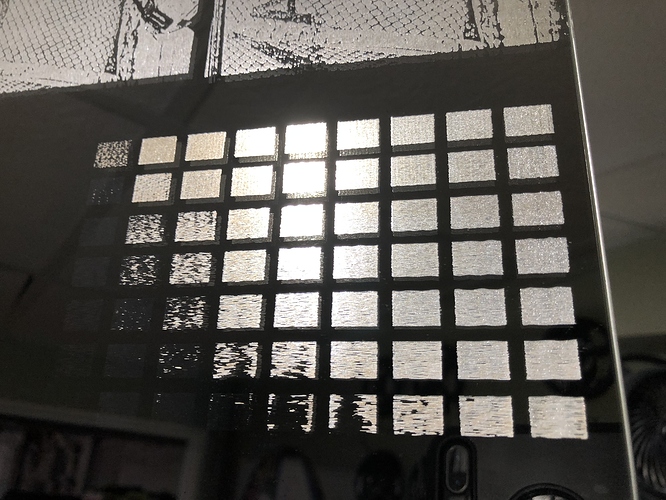

So I ran the file on 2 different materials the wood art boards I have been using and the mirrors. How would you decide which settings to use? The 400 at around 50 or 60 percent look about the most shades to me on both materials… but it doesn’t make sense that I would run both at the same speed and power given how different they are

For images, you’d usually want a setting that gives you the darkest burn with the shallowest cut, otherwise you’re likely to over-burn. When doing photos, it’s also important not to go too fast, because small dots that happen from dithering can get skipped, and you don’t want the DPI too high, or you’ll get overlapping burn as well.

There are a lot of variables, so for images it’s a good idea to do a thumbnail pic or a small gradient with a bunch of different settings to see how they react, and every material is different too. With an 80W tube, you’ll probably be looking at somewhere between 160 and 200 DPI for optimal.

So I am looking to just zero in on one tile and not the series of tiles? (shades of gray)So of those matrix images which squares would you choose?

Try burning something like this in a grid instead:

If that comes out “true” - as in, shaded from black to white, with a smooth transition, you’ve got the settings right. Image burning is different than just burning a filled shape.

What would be a good speed and power to start from ?

Try 150mm/sec, 10% power, using Jarvis dither, with 180dpi, and see how it looks. That is a complete guess, but it’s a start.

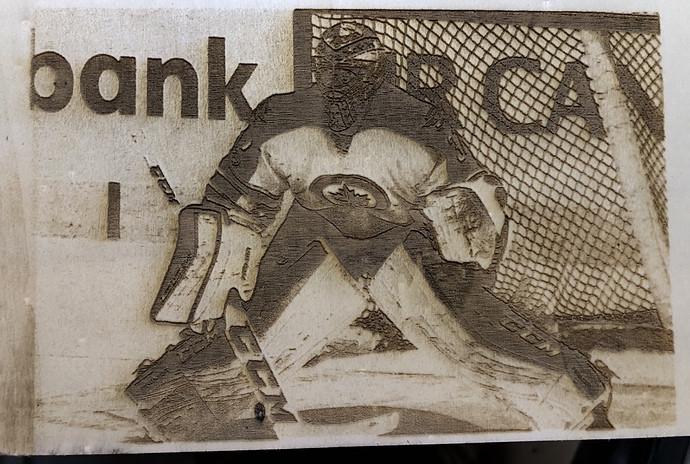

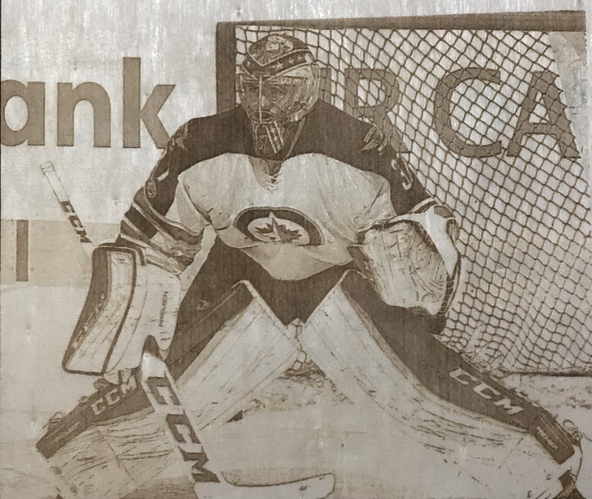

That looks much better!

Yes. Now on to mirrors and clear glass.

180 dpi seems to be the sweet spot for my laser. I did a test on some white aluminum and it turned out even better then the wood. Would I use 180dpi for all my work then?

You can play with it a little, and it may vary a bit on different materials, but ultimately the limit is the size of the smallest spot your laser will make on a given material. Bigger tubes have a bigger spot size - my 100w is close to 0.2mm (130dpi to 150dpi) so yours sounds about right.

Ok… that is great info. I think that will help me get these things dialed in.

You did so good with that photo information. Do you have any setting suggestions for a 40 watt blue and white machine?

Jason, did you use Jarvis or grayscale on that photo?

I used the built in Jarvis settings.

I would try similar settings maybe a bit less speed for a 40watt

thank you for the information. I’ll try it out later.

Just wondering… Did you process the picture all in LightBurn or did you use another program and then put in LB?