New to this forum and am very impressed with this software. I have an Atomstack X7 Pro and apologize if this ends up on the incorrect page. Has anyone added a laser pointer and successfully been able to get the offset setting to work when using negative values? My pointer is technically in the negative values on x and y. I can get everything to work minus homing. If I turn the settings on after homing the machine all seems to work. The machine will “crash” if sent home with negative values. I have searched and searched and found a couple of topics that are close but just not the same issue.

xTool D1 uses a negative offset for their standard configuration.

What happens? I didn’t think homing was in any way tied to laser offset.

Are you using the term home to mean “go to 0,0” or something like that? Or are you talking about initiating a homing operation?

Does your machine have homing switches?

Can you confirm where exactly on the laser head you’ve mounted the pointer?

As an aside, is there a reason why you’ve added this pointer? What is the purpose for it?

xTool D1 uses a negative offset for their standard configuration.

I had an xTool D1 and could not get over it not having limit switches. Having the D1 caused me to grow attached to the pointer.

With the offset on and negative values entered the machine will try to drive itself past 0,0.

I 3D printed a mount that also holds the pointer and an air assist tube that runs into a printed nozzle. (Thank you, Thingiverse!) 0,0 on the X7 Pro is at bottom left. The pointer is located x and y negative beyond the limit switches defined 0,0.

The purpose of the pointer is to realign items that were cut or etch by mistake. For example, I was testing a new pattern on a tumbler tonight and was using the blue tape method to check alignment. Well, after a few test and no markings on the tape, my last setting was just barely to high and faint markings were left on the cup. The markings were to light to see in the camera to realign but just dark enough to see. The pointer would allow me to physically see the trace and could have saved the tumbler. Maybe I am going about it the hard way.

Is the pointer easier than using the primary laser light in some way?

I’m trying to sort out how this works. I don’t have a pointer but feel like this should work.

Can you validate these assumptions:

- Your X7 Pro has limit switches

- On startup, the X7 homes to the bottom left

- After homing, the machine reports 0,0

Questions:

- Does the homing process accommodate for the additional area taken by the pointer? Meaning is the pointer distance accounted for in the final homing location?

- Since the laser pointer is at lower-left of laser head, that means that after homing the laser head should need to pull away up-right the distance from the primary laser beam and the pointer. Not doing so would allow you to point to a location that the primary laser could not physically shift to.

- I think as you’re getting to, have you considered mounting pointer to top-right? might obscure the pointer but would make it easier to deal with the geometric limitations by simply reducing your work area.

First off, thank you for your time and your help! It is greatly appreciated!

Is the pointer easier than using the primary laser light in some way?

In my case, the air assist nozzle that i am using replaces the window and makes it very difficult to see the laser.

I’m trying to sort out how this works. I don’t have a pointer but feel like this should work.

Can you validate these assumptions:

- Your X7 Pro has limit switches - Yes

- On startup, the X7 homes to the bottom left - Yes

- After homing, the machine reports 0,0 - Yes

Questions:

- Does the homing process accommodate for the additional area taken by the pointer? Meaning is the pointer distance accounted for in the final homing location?

I feel that this is the root issue. I expected the machine to home to 0,0 and then move off of this point by the values entered for the offset. Then when a program is loaded, the machine would return by the offset values and process the job. - Since the laser pointer is at lower-left of laser head, that means that after homing the laser head should need to pull away up-right the distance from the primary laser beam and the pointer. Not doing so would allow you to point to a location that the primary laser could not physically shift to.

Exactly. The machine tries to physically move to the negative values instead of offsetting the 0,0. - I think as you’re getting to, have you considered mounting pointer to top-right? might obscure the pointer but would make it easier to deal with the geometric limitations by simply reducing your work area.

This may be the final fix.

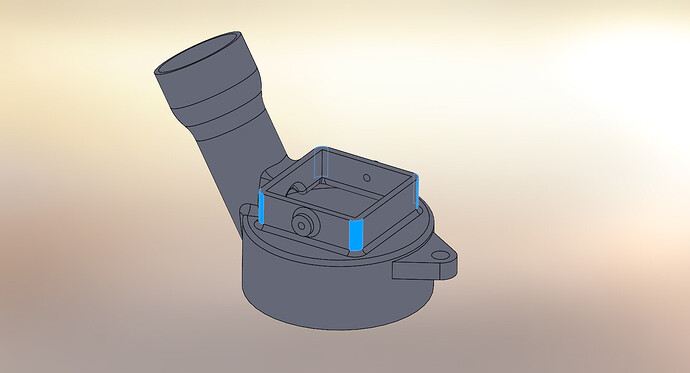

I just added a small laser module to my Atomstack X7. I 3D printed a vacuum nozzle that surrounds the square base of the laser head. It has a hole in it for the air assist and an integral mount for the laser. The laser is on the front side of the laser head and the vacuum hook-up is on the rear side of the laser head. I ran some twin lead wire to the control box and share the ±5V that powers the light in power switch. I use -43mm for the Y and 2mm for the x. The prototype was made in two pieces, the vac pick-up and the laser mount which is CA glued on (hence the 2mm offset on x). I got the settings by burning a hole in my waste board then jogging the pointer to the hole. That became my offset numbers. Here is a JPG of an early prototype (before the air assist hole and other features).

Thanks for the reply. Very nice design! So, are you using the -43mm and 2mm successfully with the “Enable pointer offset” enabled? This is where my issue comes in. My values are -28.5(x), -26.0(y). I can add these values to my actual and get my exact location but I feel like the software should do this for me. Do you only enable this after homing out the machine? (Looking forward to seeing your final design!)

Actually after tightening some things up I’m Y= -43 and X= -2

As of lately I get an Alarm 8 and can’t home the laser. But I rarely work to the coordinate system anyway. I just put my laser pointer dot at the origin or the work piece (whether that be the lower left corner of it or the center). The offset makes the laser think it is the pointer.

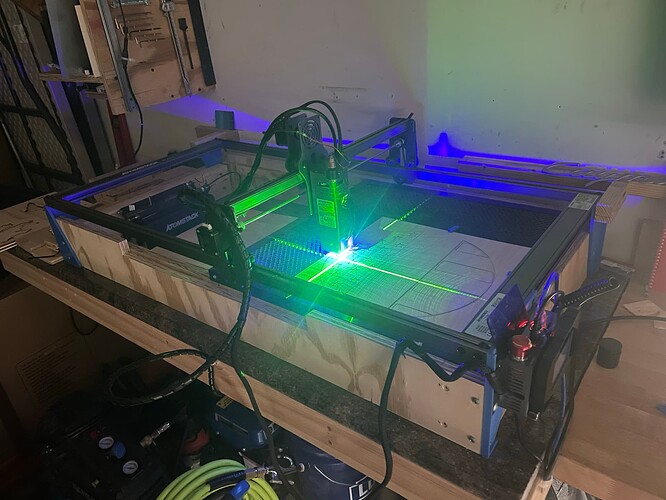

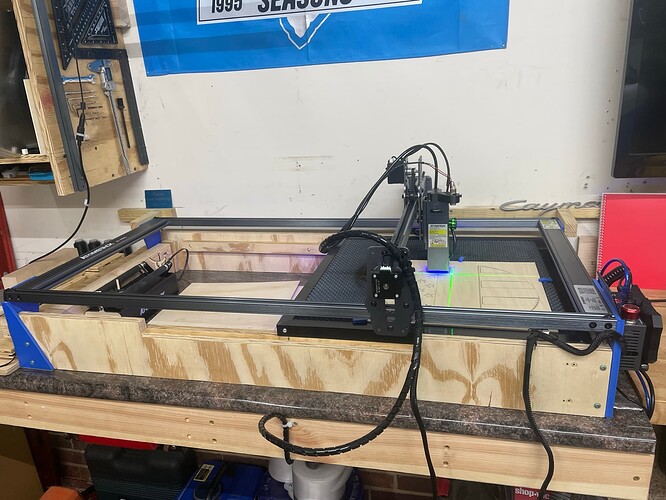

Here’s a couple pics of it on the laser.

Well, not sure what changed,maybe something in the last update. When I turn on the offset now, everything works as it should. The machine homes out fine and the offset is applied. I must have been doing something wrong the first go around.

I really like your approach to adjusting the height of the machine!