Just wondering how usefull a laser pointer is attached to my Sculfun laser? How are you guys making use of one? I did find that Lightburn will let me turn my machine laser on while framing (lower the power, press shift key and frame) . Also the laser positioning tool. Are these more useful? Is there really a place for using an extra laser pointer?

Thanks for any advice

New laserER

Greg

For visible lasers, I think it’s mostly personal preference. Mine came with one. I tried it a few times and found it useless. Further, using it reduces available workspace, making it doubly useless…for me.

Some are better than others. Mine is on the far/blind side of the laser and over 50mm offset from the laser center, while I have clear sight of the main laser beam with the safety shield removed (also useless for me)

For non-visible lasers (CO2), they usually require no offset and are the only visible indicator of exact laser position. So, on those machines, I assume they are nearly mandatory.

…that makes it useless.

On my old (sold) K40 I made a cross laser system with cheap diodes, it worked very well for me. On my OMT 60 I have made a new holder for the red light diode which is much more stable and points exactly in focus (when the height - focus is correct) I use it without noticing it and don’t want to miss it. But there are many here who have never had their “helper” diodes set up properly and don’t like it - ok with me.

You’ll find a range of answers from useless → can’t live without it.

My first machine, the root cause of my addiction, used the laser itself at low power to frame. This was frustratingly slow on a CNC3018 ![]() If I tried to locate it for accuracy from another cut, forget it.

If I tried to locate it for accuracy from another cut, forget it.

In my personal experience, I’ve found them, generally, worthless. I have a few dpssl, a co2 and a fiber.

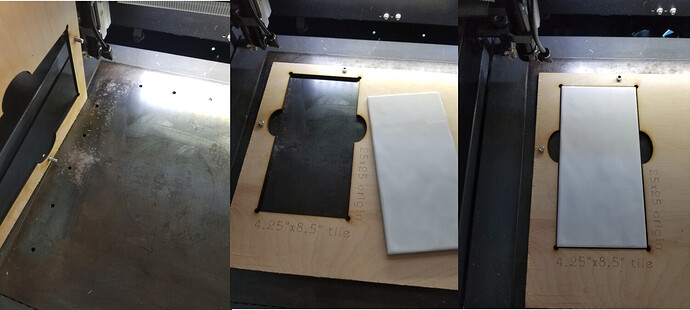

I use framing on the fiber for quick stuff. But there’s no real reason to have it exactly correct. When I do something like coins where they have to be exactly centered. I cut a circle groove in a steel strip that will seat the coin, thereby aligning it.

On the co2, every time I went to use it, I had to adjust it. You could only adjust it with acrylic as you could see the beam go down the hole.

When you have different lenses and the alignment beam doesn’t come out of your lens, then it has to be adjusted each and every time a lens change is made. Even then, the dot is huge and bright compared to the laser, making it not accurate to visually align the material by the diode itself.

I think the solution that @bernd.dk used on his K40 is probably the best option. It’s only drawback is there is a lot of mass for a dual diode on the head. Even these have a larger dot than that of the laser.

@cggorman advised, you usually lose workspace when using one that hangs off the side for many dpssl machine.

I have resolved to using jigs in my machines.

On the fiber, I cut a grove that will accept the coins edge. A slightly indented area for locating the part.

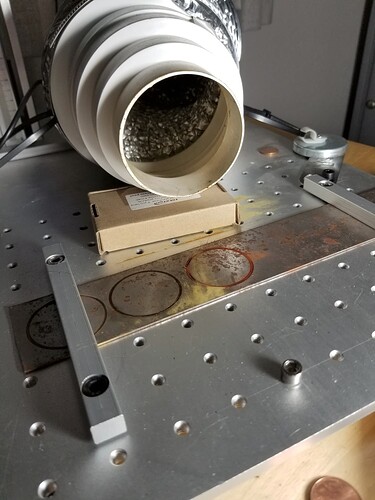

On the co2 I have a steel bed with holes in it for alignment, then I cut out the area I need to locate the object.

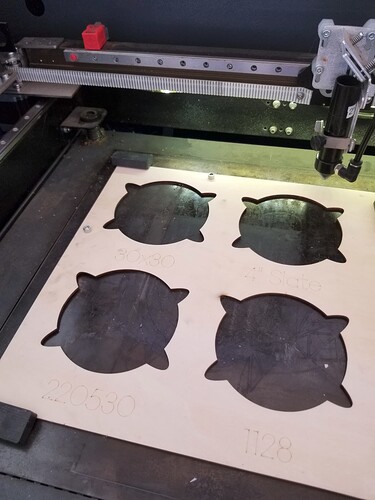

I placed the origin of the material at a certain spot. I can move the gantry to that setting and make that my origin. Then I run with user origin for each part. If I’m running more than one item I can run in absolute coordinate and do a batch, like these for slate coasters.

To clarify @cggorman, on a co2 you have to have a tube that has a factory aligned beam combiner inside it, or an external beam combiner to have the led alignment beam come out of the lens itself…

Russ Sadler has done a bunch of videos on this exact problem with co2 gantry lasers. Might want to check him out… I notice he doesn’t appear use them either.

This is the one I’d probably suggest for showing how it’s not what you think… I think his phrase "it will get you in the ball park echos clearly on their effectiveness.

In the end you will have to try things and figure out what works best for you, your machine and how you do things… So pick your poison, so to speak.

All this is education… all you can do is profit from it … and nobody can take it away.

Good luck

![]()

Even after considering all the pros & cons, and all the valid issues that folks have with it, I fall on the “really like it” side of the fence. Yes, it’s a crutch, and I’ve gotten dependent on it being there, I do use it. I had to get creative when I swapped out the OEM head on my 60W OMTECH, for one of Russ Sadler’s lightweight heads. I just went on TinkerCAD and designed an articulated red dot pointer holder, to mount on the right side. There’s plenty of room, so it doesn’t get in the way of anything. I also bought a better pointer from Cloudray, that can actually be focused to a dot, and I will be installing that soon. It works for me.

BTW Jack, thanks for the air tube mount idea.

As I said, I am new to this and sure appreciate all your input! I have been 3d printing for 3 years and really looking forward now also to laser. I printed a battery, laser and switch holder and attached it to the screw on the left side of my laser shield and takes up no space at all, but then discovered the built in lightburn tricks and was wondering about need for the pointer.

Thanks again

Greg

PS ; would like to post a picture but don’t see how to do it

If you are coming from 3D printers, there are some things to learn / get used to. In some aspects, lasering is quite different. I was also coming from 3D printing and was wondering how a laser ever could work without limit switches etc. (and actually, you don’t need limit switches at all ![]() ) During the years, you will learn new habits for the laser, and notice that many initial assumptions are not true.

) During the years, you will learn new habits for the laser, and notice that many initial assumptions are not true. ![]() Just find your preferred way of working, it will improve over time anyhow

Just find your preferred way of working, it will improve over time anyhow ![]()

That’s actually the “old” way of doing it. Enable the fire button in device settings and “turn on laser while framing” as well, you don’t need to press any key then. Just click on frame and the laser is turned on automatically.

Some more tips for your Sculpfun: Setting up the software - Diode Laser Wiki

I am actually enjoying the laser pointer. Useful when I need to rerun a cut, (pick it up to examine, then replace in exact spot) easier to follow the frame ( hard to see the laser itself, through the shield etc). Not really returning to home anymore, just move laser to whereever and go.