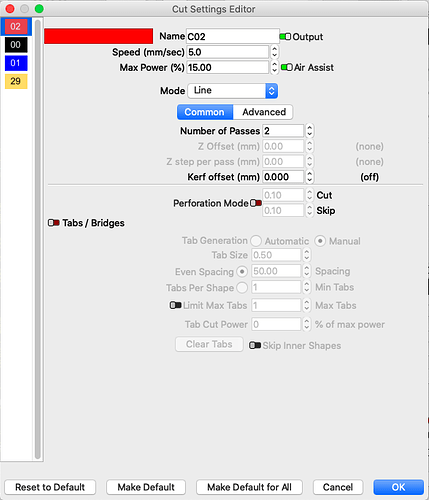

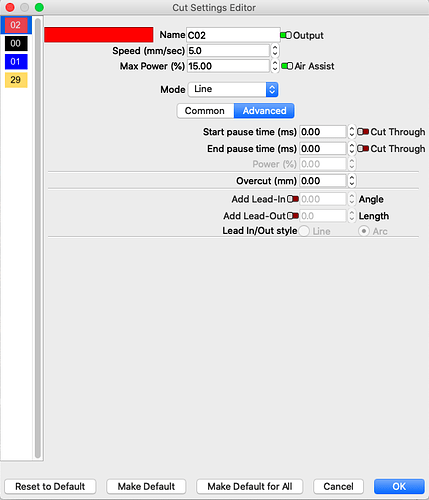

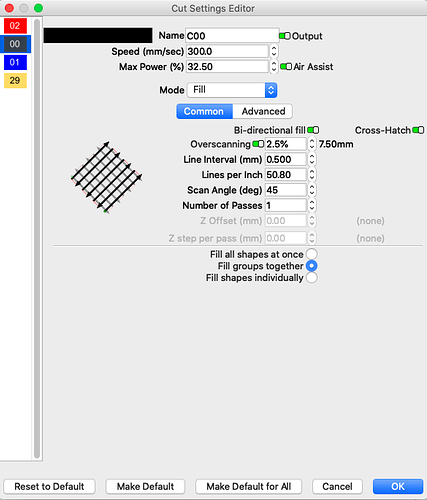

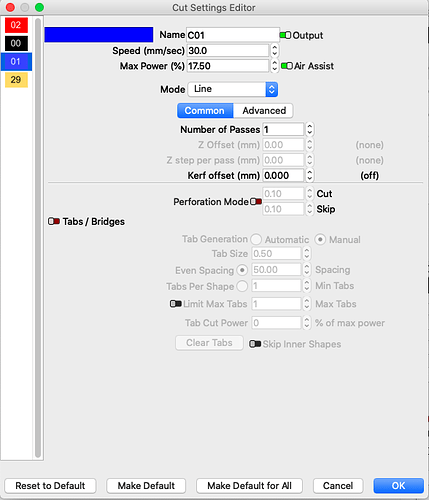

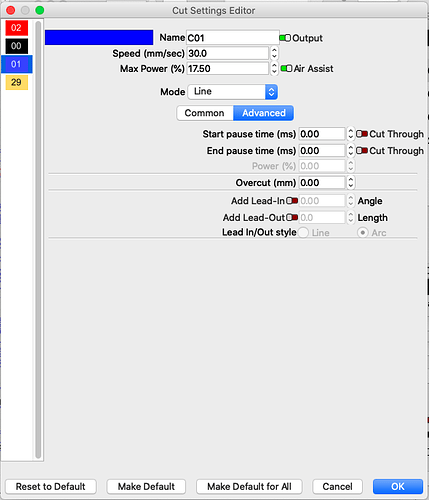

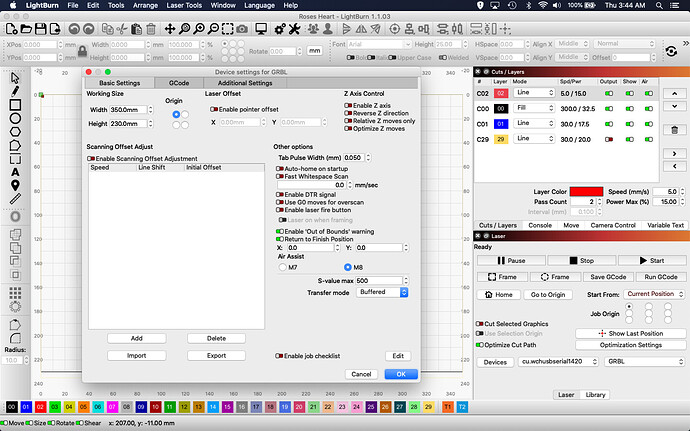

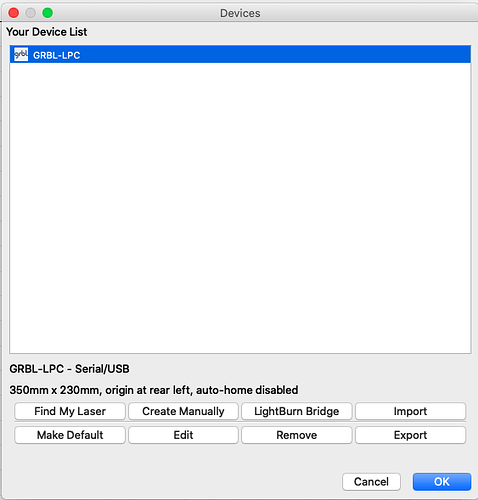

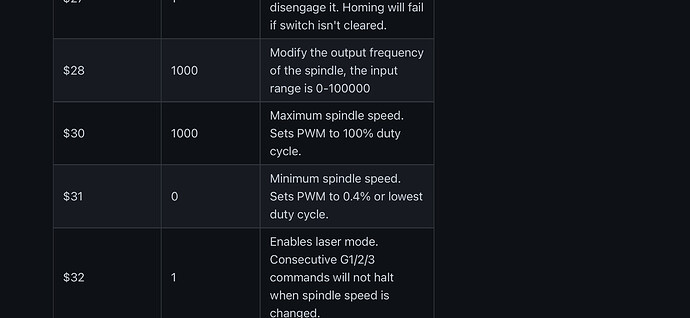

Hello, I recently replaced the nano board in my omtech K40 with an MKS DLC32 v2.1. The documentation I was able to find says that this controller ships with GRBL 1.1f. I’ve uploaded both my project and the machine settings I’m using.

The problem I’m having is sometimes the laser turns off during both cutting and engraving leaving me with incomplete shapes or cuts that don’t go all the way through the cardboard.

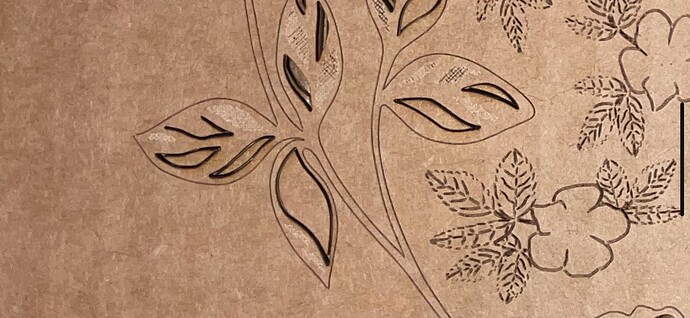

Here you can see where the laser turned off halfway through the cut and some weird crosshatching.

Another incomplete cut and the crosshatching is one directional.

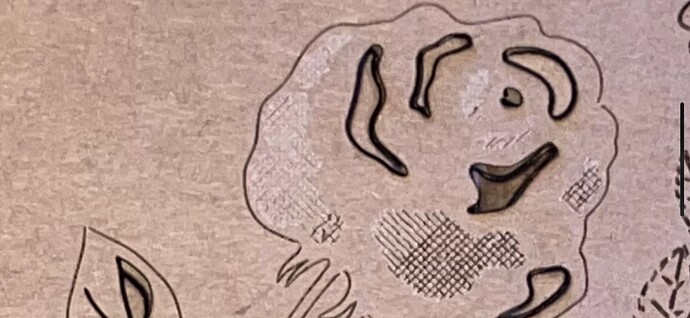

Here the crosshatching looks weak on the left and incomplete on the bottom of the flower.

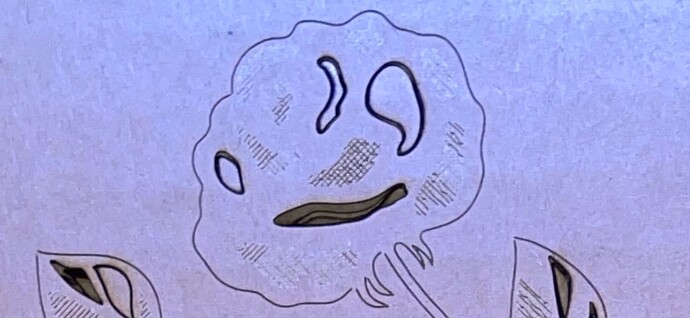

Some more incomplete crosshatching.

So far I’ve tried various speeds and power settings thinking I wasn’t running it hard enough to trigger the laser coming out of corners but no luck on that front. I tried changing my S-min from 0 - 50 - 100 - 150. This didn’t seem to make any difference except that I started having issues with the cardboard catching fire. I switched to 1mm plywood for a few tests so the material wouldn’t burn as easily but even with higher power settings there were sections that the laser wasn’t firing. In the project I uploaded the cut power is lower than I’ve been running, I was up to 22.5% and on my most recent attempt I turned it down to 15% and ran multiple passes. My blue layer runs at a faster speed and a lower power setting than my normal settings for red and black and it doesn’t seem to be missing anything. It doesn’t seem to be related to my power setting or the S-min setting but I could be missing something.

I’m using the shielded USB cable omtech sent me with the laser and before I replaced the nano board this was never an issue. I took some time to clean up the wiring to the control board and moved the stepper wires as far from the usb as I could then moved the board as close to the opening as I could so as little of the USB cable is with all the wiring inside the case as possible. As it is I have less than 1" of USB cable sticking into the machine to try to reduce any noise it might pick up from the other wiring.

Here’s where it gets weird. On multiple pass operations like my cut lines(red) I noticed that sometimes the laser DID fire in the sections where on previous passes it had not fired. It’s intermittent though and I don’t have a way to tell if it will fire or not on subsequent passes. I ran the cut lines for a total of 6 passes and still it’s missing bits so extra passes as a workaround won’t work.

There are a few other quirks since I replaced the nano board that may be related but I don’t know.

I have to draw a box around the entire job or the cut and engrave layers don’t align when the job is finished.

Sometimes after I change machine settings I lose connection with the control board and have to restart LightBurn, the machine, or both.

Sometimes when the job finishes, LightBurn just keeps on counting the job time and it says the laser is busy until I hit the stop button. There are no new messages in the console for clues when this happens but I don’t lose connection and it doesn’t seem to be hurting anything so I haven’t worried much about it.

On a handful of occasions the laser has just stopped with no alarm or message of any kind. The machine status reads ready when this happens to me. I can home and start from the beginning again but I have no idea if there’s a way to start the job again from where it left off. Because this is practically impossible to reproduce at will and doesn’t happen very often I’m not focusing on it but I wanted to share in case it’s related.

Any help would be greatly appreciated.

Roses Heart.lbrn2 (2.7 MB)

omtech K40 machine settings.lbset (5.9 KB)