I’ve got a 12x20 cutting area and am trying to engrave a photo onto an 8x10 piece of wood. No matter what I do, every time I run the cut it tells me that the file exceeds the working format. This usually means that my origin is set wrong or there is an artifact outside of the software cutting area. However, I’ve checked both of those, even tried changing the size of the cut, and it still happens. Any ideas?

Please post a screenshot of your entire Lightburn screen with your project loaded and the Cuts/Layers Panel and Laser Panel visible. Also post a screenshot of the Settings Window (Gears icon) with the Units and Grids tab visible and post a screenshot of the Device Settings Window (Wrench and Screwdriver icon), finally post a screenshot of the preview window with “Show Traversal Moves” checked.

I get this when my work piece is too close to an edge. It may frame ok but it will not engrave.The laser head actually goes past the engraving when it is burning. It cannot do this if you’re already at the limit of movement. Try moving your work piece toward the middle of the bed.

It’s more likely that it’s as @1Vince has mentioned. The overscan is driving it out of your work area.

You can use one of the on-line calculators to determine how much room you need to reach the target speed. If it needs more than travel to reach that speed, it will give you a slop error or something similar.

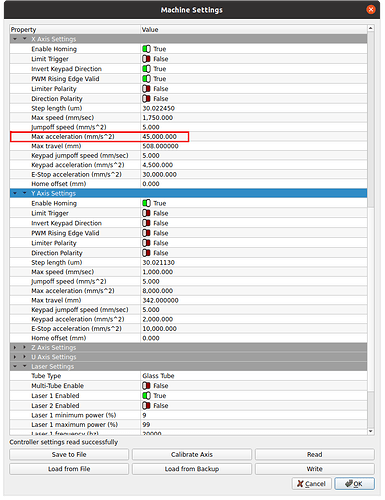

How fast are you attempting to run and what is the acceleration of the axes?

![]()

Ah that makes sense. I believe I was attempting to run it at 200mm/s so it makes sense that the laser head might not have enough time to actually reach that speed if it’s right up against the edge of the working area. However I’m not sure what the acceleration was, I’m still very new to laser cutting so I’ll have to figure out how to check that. I will try the cut again in a couple of hours and update how it goes.

There is one for each axes and also some control in the cut/engrave sections on the device. You’re acceleration value will be much lower than mine.

![]()

I was able to place the project in the middle of the cutting bed and it is now working just fine now. Though it is good to know about those acceleration controls. Thank you so much for the help!

Hello, I also had similar problems at the beginning.

It is necessary to check in basic parameters that the values of the dimensions of the table are correctly entered.

In the displacement window, you must create a 0.0 original position where the head should be at the beginning of work if there is no 0.0 sensor (usually in the bottom left).

Another “center” position can be created with veleur in the center of your table.

This helps to verify that the head movement is moving to the right place and that the communication port is not blocked which happens to me.

Finally there may be other forms on the worktable but only those which are selected will be machined. You have to be careful with those that are outside the table and that are sometimes just simple points forgotten.

Good follow

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.