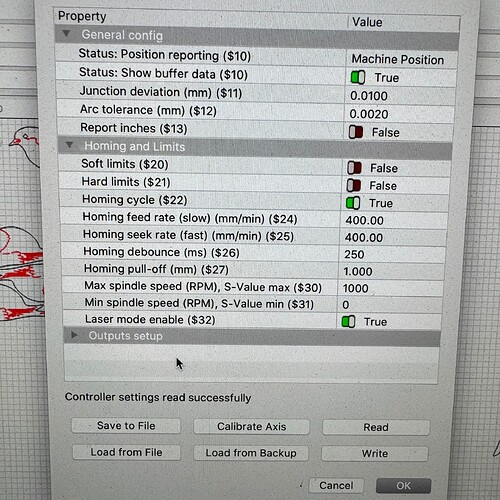

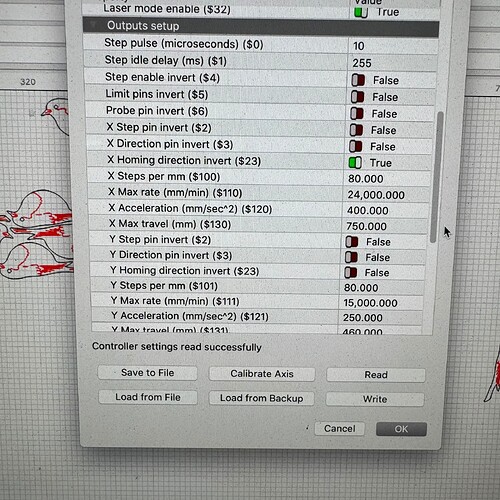

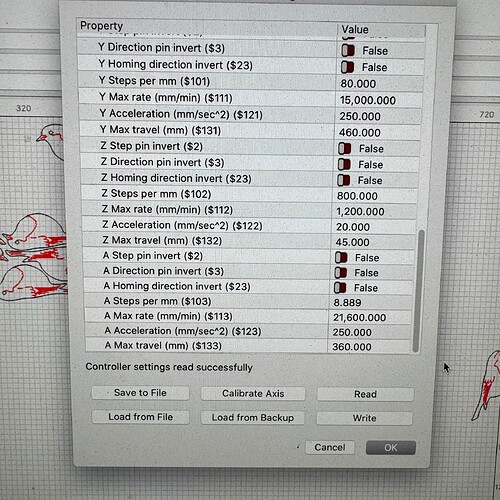

Mac Ventura, lightburn 1 6 03 neje max 4

Never had this problem before upgrading to lightburn1.6.03

when engraving, which is most of my workflow, the laser starts each line 2mm to the left of the last, so quickly runs off the wood I am engraving. Sometimes if I rotate the engraving 90 degrees it engraved okay but id I duplicate back to the same issue. I have noticed that when framing multiple times the laser head does the same. some screenshots above

You have loose bolts or set screws somewhere in your machine. Check your X axis mechanicals - drive belt, pulley and idler wheels

It’s a mechanical issue. 99% certainty. Your settings might have changed by the upgrade, that’s why it looks coincidental, but it won’t, I think.

Still not got to the bottom of this.

New machine and checked all the x axis, everything seems fine.

If mechanical why can I use it perfectly for a couple of hours and then it starts playing up?

Turn your image 90 degrees and engrave again.

Slow down the laser head. How fast are you trying to engrave? Cut that speed in half and try again.

That, to me, looks like your nozzle may be dragging on your workpiece. That is, raise the laser and see if the problem goes away. The wood in your pictures does not appear to be “flat” (or at least not coplanar with your laser axis).

Thanks for the replies. Nozzle absolutely not anywhere near the wood. I always dial my speed down as a matter of coarse as I like deep engravings.

The machine when jogged on x axis always goes to the left of where it should stop.If i jog 80mm to the right and then back to where I started from it overshoots by 2mm. If I jog 250mm to the right it overshoots the mark to the left by about 10mm. I think therefore it must be a setting in LightBurn or the controller on the laser?

What settings would I need to change to sort this problem?

I would bet money that you have a loose set screw on your X axis motor pulley. The reason it starts fine then gets worse the more you use it is heat causes a slight expansion of the pulley and it starts slipping on the shaft. Mine has 2 set screws on the pulley so be sure to check both if it has 2.

I have done everything mentioned here and I am getting better results and then it gets worse. It is not right, finding that sweet spot with belt tension is almost impossible. This is not how it is meant to be.

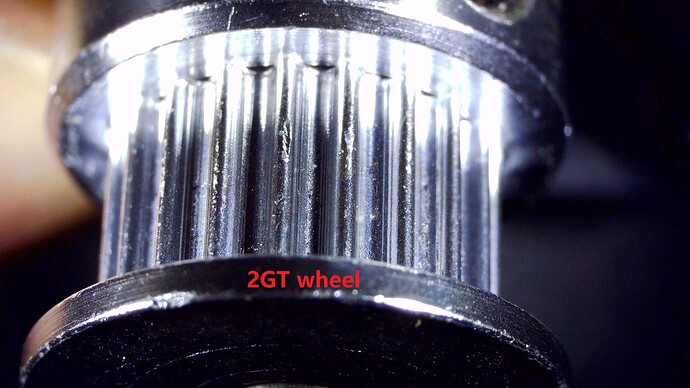

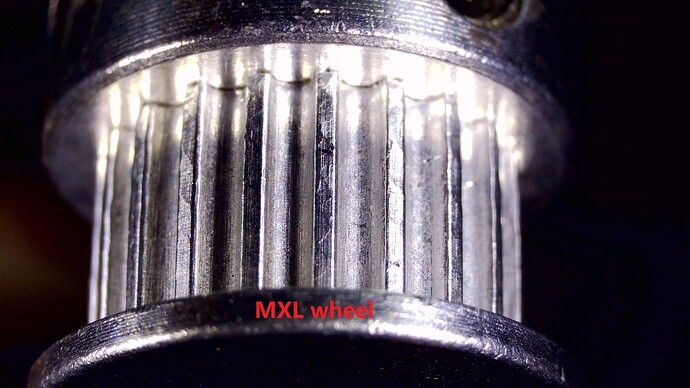

Talking to NEJE it appears that they have put the wrong pulley on the stepper motor for the belt they now use, only affects some machines. They have communicated with quickly and progressed the issue through to their technicians. So far so good. and will be sending me a new stepper motor.

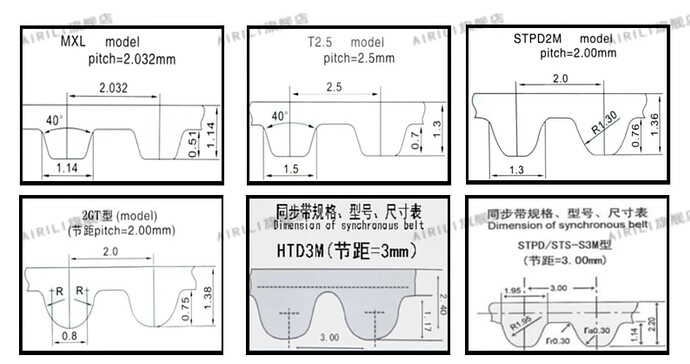

“The model of our current synchronous belt and synchronous pulley is 2GT. We may have mixed MXL synchronous pulleys in some batches of products. If 2GT belts are used with MXL synchronous pulleys, the travel length may be incorrect.

Please check whether your synchronous pulley is 2GT or MXL. 2GT synchronous pulleys have round teeth, while MXL synchronous pulleys have square teeth.”

That makes perfect sense with your results. Looks like it’s skiping 1 tooth every so often.

New pulleys and belts sent by NEJE, works perfectly now. One simply mistake by the manufacturer and I have wasted hours not earning a living. They did sort the problem and communication was quick and effective.

It’s unfortunate that you had to go through this, but it’s encouraging that the manufacturer actually solved your issue. I hear so many stories of a total lack of support by many of these companies.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.