I have done everything mentioned here and I am getting better results and then it gets worse. It is not right, finding that sweet spot with belt tension is almost impossible. This is not how it is meant to be.

Talking to NEJE it appears that they have put the wrong pulley on the stepper motor for the belt they now use, only affects some machines. They have communicated with quickly and progressed the issue through to their technicians. So far so good. and will be sending me a new stepper motor.

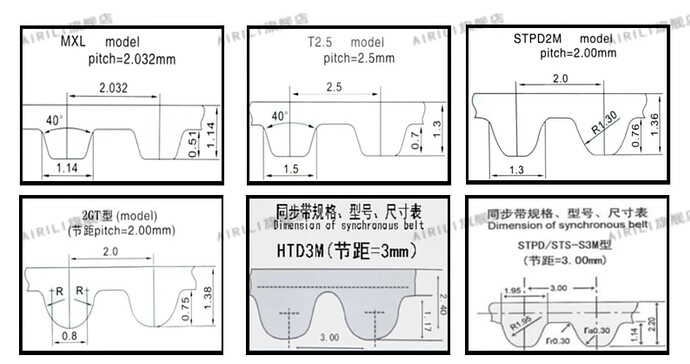

“The model of our current synchronous belt and synchronous pulley is 2GT. We may have mixed MXL synchronous pulleys in some batches of products. If 2GT belts are used with MXL synchronous pulleys, the travel length may be incorrect.

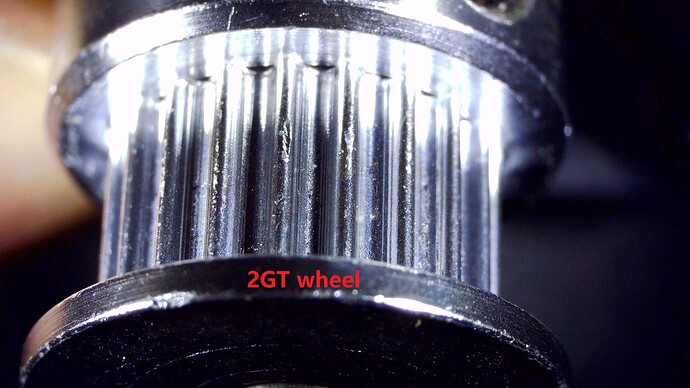

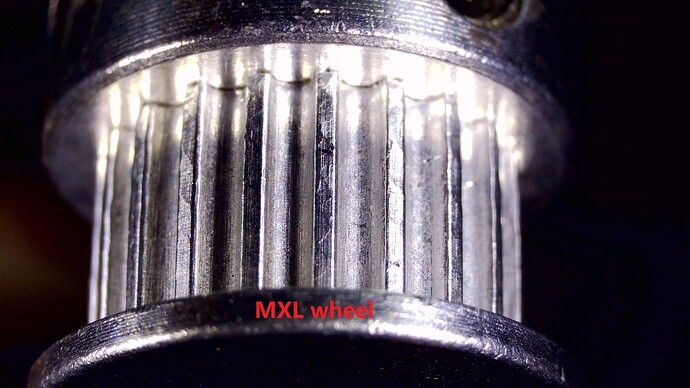

Please check whether your synchronous pulley is 2GT or MXL. 2GT synchronous pulleys have round teeth, while MXL synchronous pulleys have square teeth.”