Hello I was facing the same problem with Neje Master 2 7W.

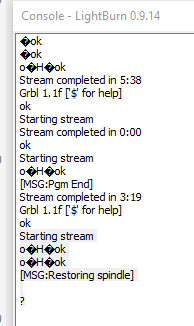

The machine stops working and the console shows this fancy character.

Rerunning the exact g-code again and again stops at different positions, so there must be sth. non deterministic going on.

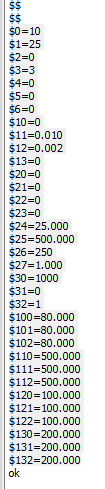

Here is my investigation …

- disabled any power-management options (e.g. for USB) at OS level.

- exported the gcode to file and tested also other g-code senders, where you can influence the sender (e.g. wait for ‘OK’ before sending the next commands).

- start sniffing the communiction, so I could see that my computer doesn’t send anything unexpected.

At this point the computer sends the correct commands but the machine responds with the fancy char.

Copy+Paste the char from the console output and converted it to hex ‘EFBFBD’ (‘FFFD’ in UTF-8), saying my command could not be converted.

This makes me think that something is not properly shielded.

- ensured that the power and the usb cable connected to the machine are not placed in parallel

- replaced the usb cable with a thicker shielded one

Still no success … very frustating.

Here I was still thinking that my g-code command get’s messed up to it’s way to the 328p chip … So maybe the machine’s board causes the trouble?

Again … out of ideas - or at least what I was willing to modify on the hardware’s side for now.

Then two things came up my mind …

- What if it is not my g-code making GRBL receiving a non parseable command

- What about time (shorter programs run successful)

So here we are … temperature?

The laser has it’s own fan, but what if this one is not sufficient?

The laser seems to have one wire that encodes the temparature information.

Without looking into any details here (e.g. how it is connected to the board and to which chips),

I just placed 3 fans around the machine and rerun my test program.

And this time it finished successful after ~35 minutes.

So I rerun the program 3 additional times, every time successful.

Solution for me: long running program needs more cooling

Because I have not checked the wiring - here is my somehow improper explanation:

- When the temparatur hits a certain threshold sth. signals GRBL, which is not properly understood

- GRBL stops processing, presenting the fancy chars back to the console

Placing fans around the machine is working, but gives not a good control.

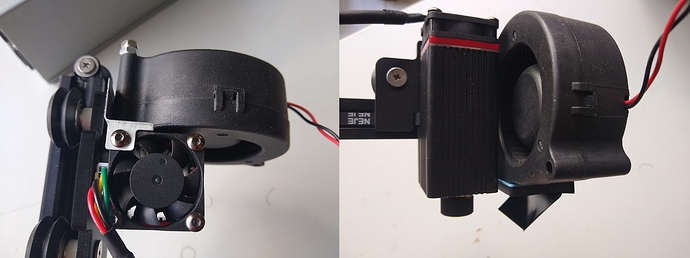

So my next setup was to mount a single radial fan next to the laser and

put some plastic sheet on the bottom to control the airflow’s direction.

PRO:

- fan cools the laser’s chassis

- ascending smoke is blown away from laser’s lense

CONTRA:

- additional weight for machine moving part

This is how the single radial fan is mounted to my machine.