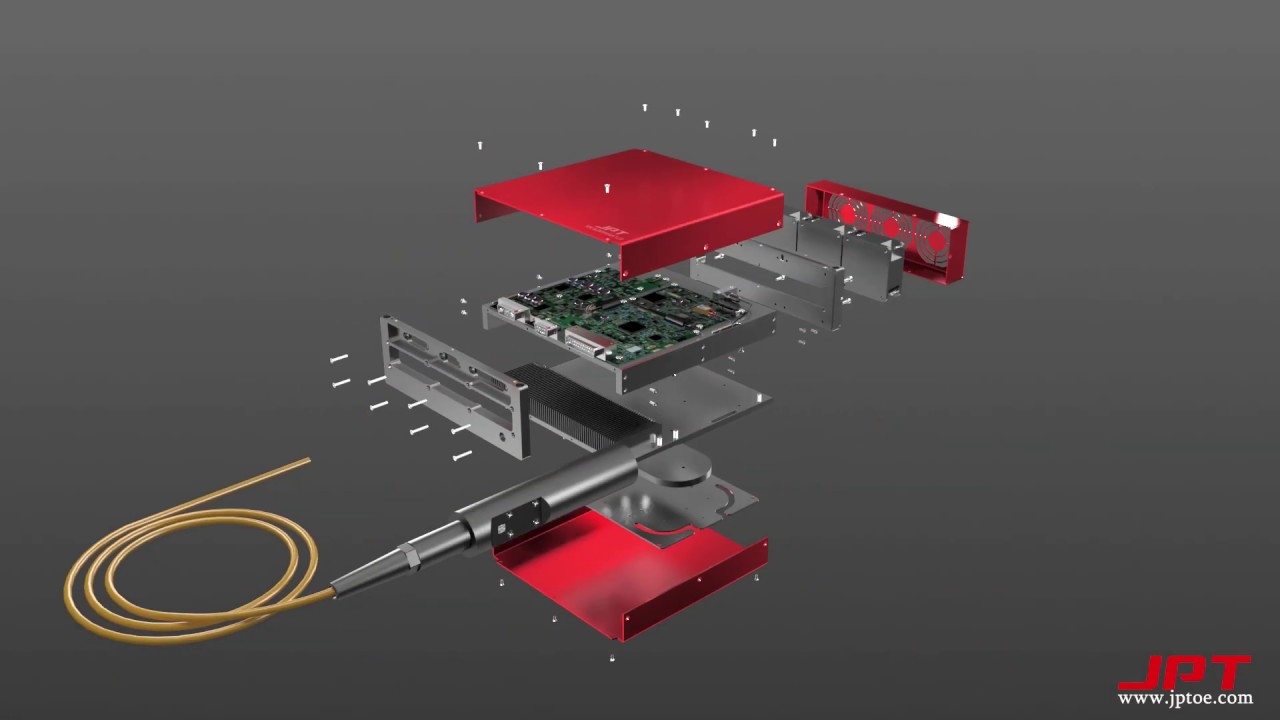

Here’s a neat video from JPT on how a MOPA works. Fun to watch, even if you don’t get anything out of it.

These are pulse machines, unlike the typical continuous wave (cw) led and co2 that we usually see.

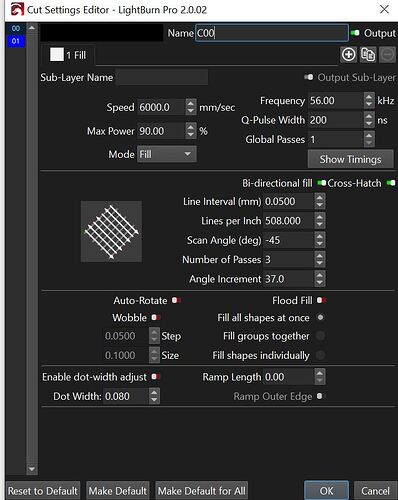

A MOPA lets you control the pulse shape to some degree.. There are discussions about this if you hunt around in the galvo area.

@misken is correct, but let me put it another way and you can pick which is more clear to you.

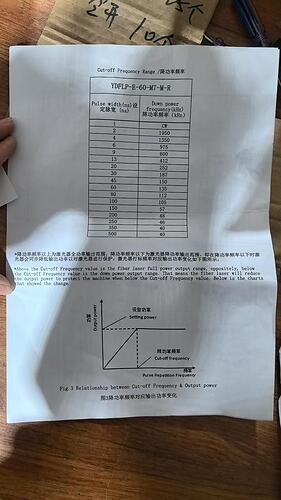

As with all circuits and systems, it takes time to pump up a fiber. Frequency determines pulses/s, higher frequency mean more pulses/s.

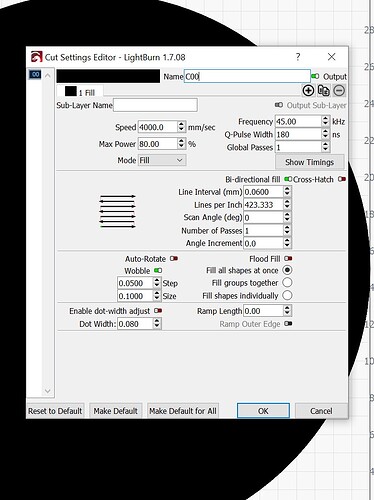

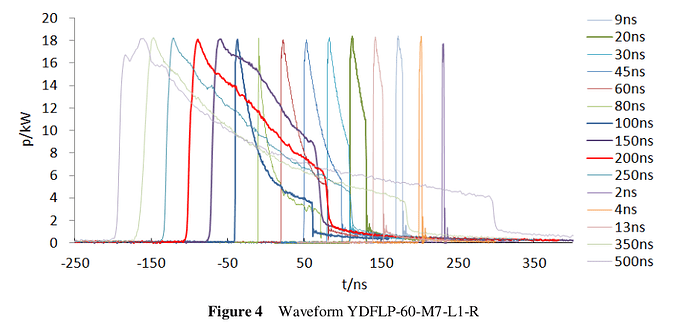

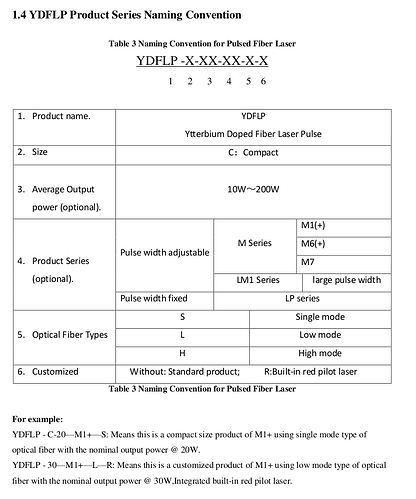

During a pulse, the seed diode controls when the energy in the fiber is released and it’s duration or q-pulse. Q is just a fancy term for a change in how well a signal is resisted or blocked. Hence the terminology of Q-switch the Q at the end of the fiber is switched to a low impedance or low Q, to allow the pulse to be released. While this Q remains low, energy of the fiber is released. Most of these pulse in the area of about 15kW, however a MOPA can change the Q pulse shape. This is from my JPT YDFLP-60-M7-L1-R User Manual-20191202.pdf.txt. It’s a pdf, so remove the .txt extension.

How long a fiber takes to pump up is based on it’s power rating, hence a 50W fiber will take twice as long to pump up than a 100W fiber… Output is similar, but the 100W allows more pulses/s, because it can pump up the fiber quicker allowing more pulses at higher power.

It’s unlikely this is an issue. These sources have lots of protections built into them, the most common that I see, is they overheat and a shutdown is triggered by the internal temperature sensor. Some have opened them up and allow fans to blow into them or just moved the machine to ensure better air flow.

Many of these, like mine, have a sensor that lowers power if there is a reflection issue.

Hope this make sense? .. A bit longer than I hoped for..

I’d suggest you ensure it can breath before looking elsewhere.

Please let us know what you find – Good luck.