SO for the past 2 days I have been trying to do a burn that is 784.9 y by 399.9xon my Ortur Master Pro 2 S2. My work was framed perfectly each time i checked. When it came to the burn it initially did from 0 to 60mm then stopped. I tried the same burn 3 times, and before each burn I framed my work, and after framing, I called it home to start my burn. All 3 times stopped in the exact same spot. I checked every last setting and made sure none of my USBs would go to sleep. Nothing worked. So I got a bright Idea to CUT my image to exactly where it stopped and do a new burn. Again I checked everything and framed my work and everything was good to go but this time it only burned from 60 to 70mm in Y Just 10mm of burn that was it but again stopping in the exact same spot. Lightburn showed it was still streaming while the laser itself was shut off but not the Ortur board… Those lights were still on. So after 3 tries on that I decided to try out LaserGRBL. So far so good its almost done except some of my burn is not showing up. I mention that because I really do not want to hear its the LASERS FAULT, because its not its Lightburn. I have seen other posts with the same prob and all the Lightburn/Ortur product people post its the laser not lightburn which in my case it is proven to be Lightburn. So How do I fix this???

Try saving the gcode for the original design in LightBurn. Then run that gcode in LaserGRBL. Do you get the same behavior as you do in LightBurn or do you get new behavior?

I will have to try that out when this burn finishes in the next few hours. Its a large burn.

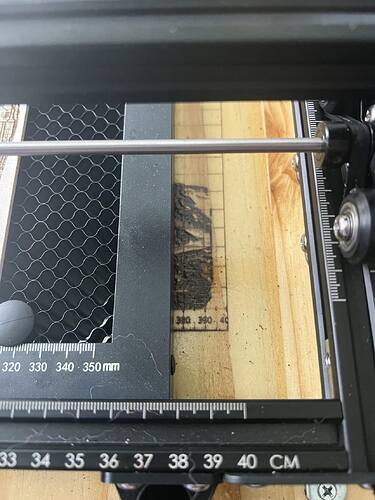

So Yeah its still a no go at this station… Still stops in the exact same spot around .230mm to 235mm. Laser GRBL just rolls through but burns higher. Any suggestions to try and fix??

Can you take a photo of the burn?

I’m not following what you mean by this. Was the previous test done using LightBurn generated gcode in LaserGRBL?

If so, this implies an issue either in the g-code generated, in the machine, or something in the communication. It likely wasn’t an issue in LaserGRBL when run natively because it’s generating different code resulting in different behaviors when run.

Can you upload the following:

- photo as indicated above

- generate gcode in LightBurn, save with .txt extension, and upload here

- .lbrn file you’re running

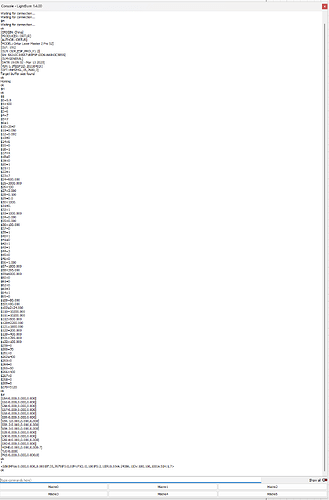

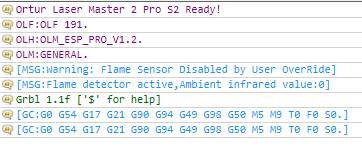

Also, are you getting any sort of error when this happens? What does Console show?

For some reason it will not let me upload neither txt file nor .lbrn

And like I said before, Lightburn shows that its still going but the laser has stopped and as you see in the pic it is the same spot as always. I did delete Lightburn from my computer system and tried to find and delete all associated files and then I reinstalled before receiving your message.

Also if you notice in the pic the full outline that was before doing the etch just to see if it would give me the full board which it did. I have a full burn from LaserGRBL from right before using Lightburn which came out a bit toasty

I placed the files in my dropbox folder

A few observations:

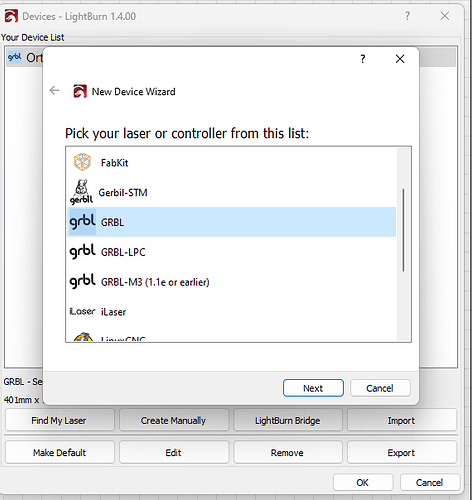

- You are using the incorrect device profile. You are using “GRBL-LPC” but should be using “GRBL”. This may be an issue with auto-detection. Push Devices button in Laser window, then click on the name of your laser, then Edit. Then select GRBL. Complete the wizard.

- It’s unclear what’s causing your burning but your grayscale layer C26 has a very high min power % of 20. Is this really what you want? I could see this easily contributing to overburning.

Neither of these things on their own should cause the burn to stop in the middle, however, as far as I can see. That’s typically associated with a bad connection or external power quality or electrical interference. Do you have other machines coming on during the middle of the burn? Perhaps an air pump? Also, is your machine properly bonded and grounded? Image burns like this can create quite a lot of static buildup. This may be especially pronounced at the top of the burn where there’s a wide area that needs to be burned. I suspect if you flipped the orientation that the failure would occur earlier.

Can you review and also provide the following:

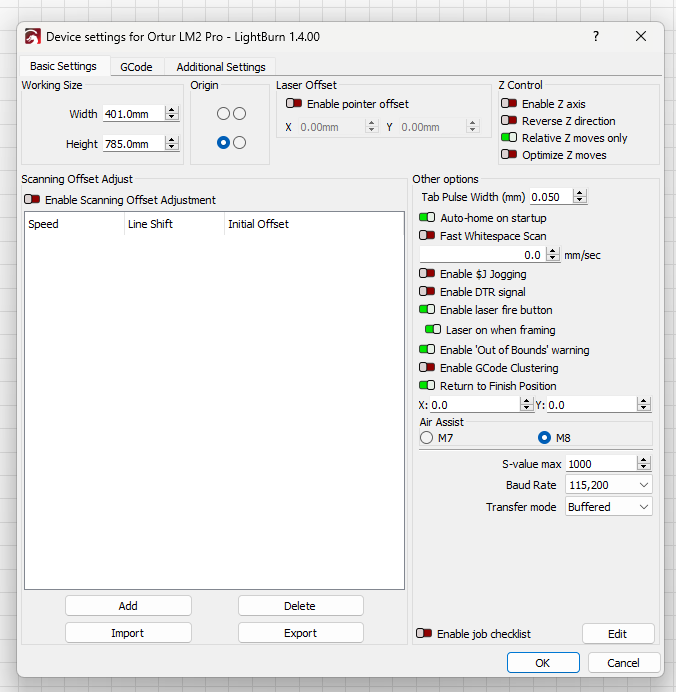

- screenshot of Edit->Device Settings

- output of these commands in Console:

$H

$$

$#

?

1. It’s unclear what’s causing your burning but your grayscale layer C26 has a very high min power % of 20. Is this really what you want? I could see this easily contributing to overburning.

It has not over burned only when I was using LaserGRBL I did a grid testing of all speeds and power and overburn was staring at 10% Speed and 40% power. Mid ranges looked best. High Power was toooo much.

It is the only Machine and yes I have the air pump on as well. Ill turn it off and check to see if that is one of the situations. And what do you mean bonded ground? I did read that some people would add a wire from the laser to the ground in the outlet. Is that what you mean? If so I do have copper wiring for it.

Bonded means that all components of the machine not directly carrying current are connected together. Grounding means connecting those bonded components to earth.

It’s possible that you were using M3 in LaserGRBL and not M4. That could cause an overburn scenario.

Can you take a screenshot of Edit->Device Settings?

Device Settings looks mostly okay but with a couple of oddities:

- the width in device settings doesn’t match your machine. 401 vs 400. Is that intentional?

- 400x785, is that the expected dimension of your laser? I was under the impression that the OLM2 S2 with extension was 390x800 from what I’ve seen online.

No that was an error on my part its back to 400 x 785. And yes the 400 by 785 is what I checked over before adding the numbers in when I built my board.

I let my huskies in to my office and now I have hair everywhere…

Same dropbox folder I sent you the link to I uploaded a video a min long showing you what happens when it reaches its own stopping point and not finishing the job. Time in LightBurn still shows its going while laser stopped.

Have you attempted to implement any fixes/changes? If so, what you have done?

What does it show in Console when the job stops? What do you need to do to recover from that point?

Situations where laser stop running but LightBurn still shows streaming is almost always going to be a communication issue where the connection to the laser is lost.

Common causes:

- bad USB cable

- bad USB port

- electrical or radio interference

- USB hub being used

- noisy electrical circuit

- static build-up and discharge into USB port

Try one thing, try running the job in the opposite direction. Does it fail early or what happens?

So if it’s a bad USB cable then that sucks cuz this one is new.

USB ports have been switched around and I do not use a hub.

See what gets me is it’s only happening on a full etch after I changed from the 400 x 400 mm frame to the extended 400 x 800.

When I did the trace and burn of the Florida I sent you it was just fine. Did the framing and then burned the trace. With static - static usually is a stop and not in the same place. This literally always stops same place. Again it’s only happening an a etch which perplexes me. Tomorrow I’m going to try and cut the trace. I’m also perplexed because I had no problem initially when I did my ruler board I have the frame on.

Are you able to create larger burns that are made up of lines only?

Is it exactly the same spot or around the same spot?

Static is most likely to buildup during scanning operations with all the back and forth of the laser module. Is it possible that when you swapped out the cabling to accommodate the larger frame that you missed bonding one of the components? Or is it possible that one of the wires is shorting out in a specific position?

Running the job in reverse direction will tell you if it’s likely static or something else.

Some other causes of lost connection:

- bad power supply.

- inadequate power supply. This is often from upgrading the laser module without adequate power supply requirements

Same spot

How do I get the engrsving to start from reverse and work forward?