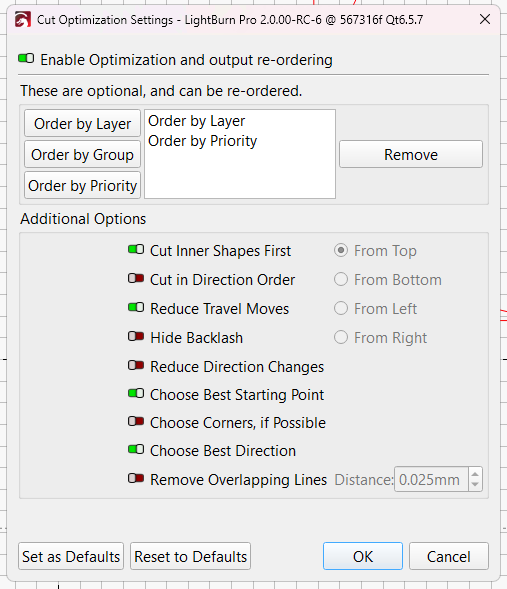

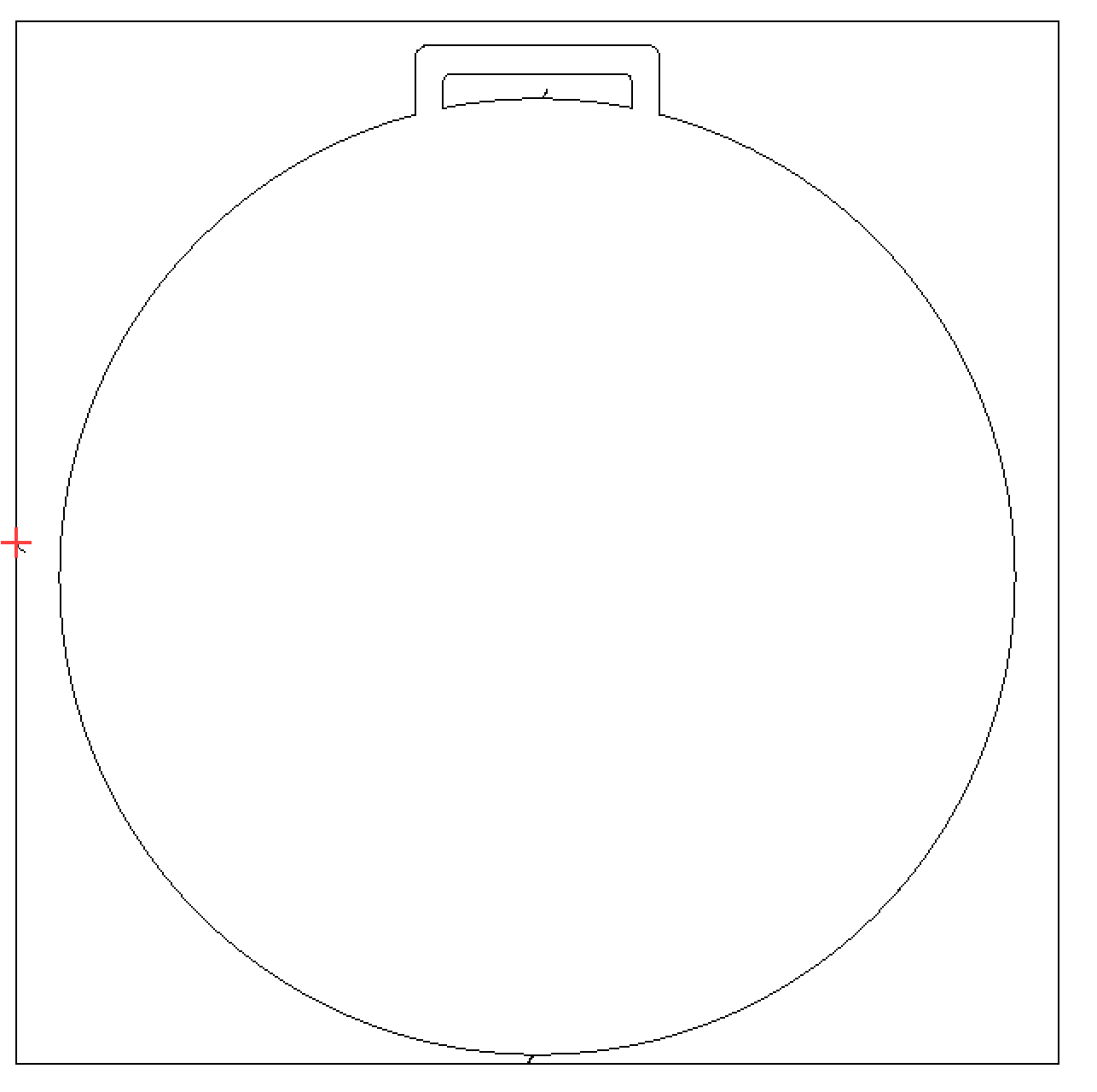

This is the shape I’m attempting to preserve.

I have it nested within a larger rectangle for a clean offcut (which can get scarred by bad lead-on and won’t cause problems in our production line)

I come from a machining background where I run CNC lasers, Plasmas, Waterjets, mills, and lathes. So I’m used to climb cuts on everything and arcing on from a positive radius.

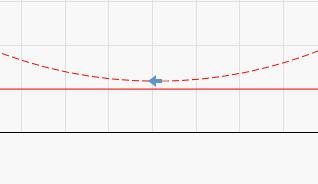

When dealing with contours we usually arc on from the left side of the cut line. This means that we run clockwise around an external contour, and anti-clockwise around interior pockets.

Thus my expected behavior is…

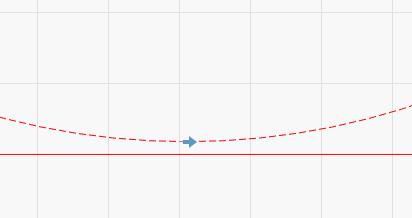

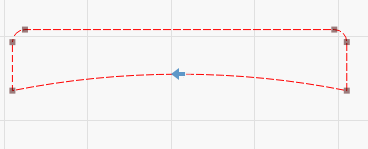

When selecting the following starts and directions:

However, reversing the direction does NOT flip the lead on to the other side of the contour.

My question is this… what precisely does Lightburn use to determine interior versus exterior contour?

I’ve attempted to toggle from line to fill and use the boolean functions.

I’ve also attempted to group specific geometry, while leaving other geometry ungrouped.

This is becoming quite an issue for us as we’re pushing out tons of new products and having to hand-hold each one, and add additional cut layers with the same speed/power settings, and all sorts of other hoops to jump through.

It’s really bogging down our efficiency on the much more complex and intricate cuts especially when we cannot get the lead on to flip to the correct side of the line on EVERY geometry with a single layer.

To go through our back catalog would be egregiously time intensive at this point, so is there another way to get the behavior I’m expecting consistently rather than using 2 separate layers with opposite direction lead on/off’s?

Cut Example.lbrn2 (12.4 KB)