@Colin

thoughts?

… ??

Um.. Colin?

Anyone?

listens to hear anything over the crickets

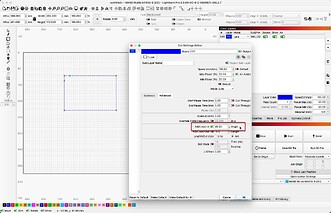

Hey @Scott1234, I am just seeing this. Apologies for the delayed response. This is a long thread, have not read in its entirety, still working through it. But had a thought, sorry if this has already been shared. ![]()

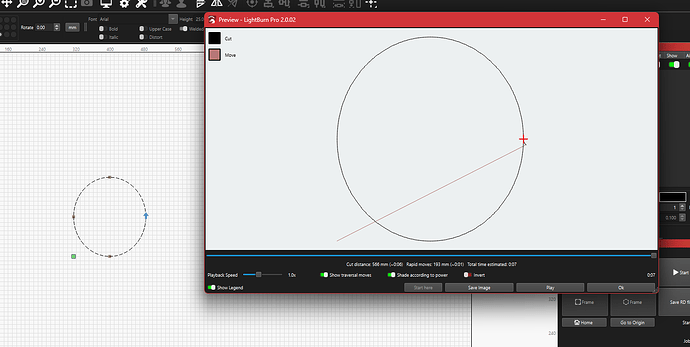

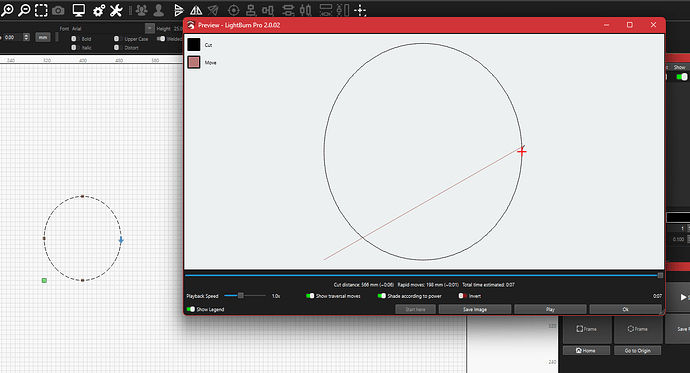

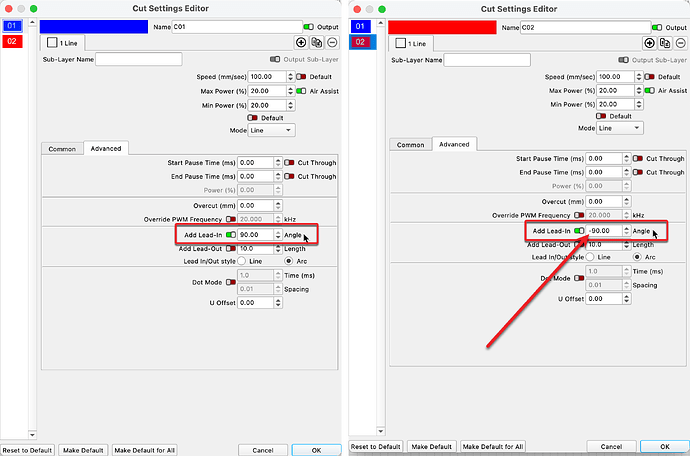

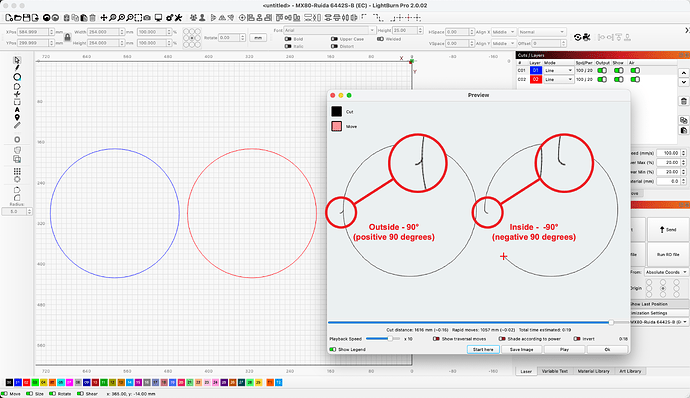

I use a negative number for Leads to change their entry point from say outside (Angle of 90.00) to inside (Angle of -90.00): I also added another node and made that new node the ‘Start From’ node to pull the entry-point away from the corner.

(click image for larger view)

Outside

-Inside

-Been through that already. Trying to keep things “sane” with one layer per cut setting so we can maximize @ materials we can use.

Ultimately I’m looking for a solution that follows a more traditional lead on lead off mechanism where lead on and lead off angle are by degrees off the direction of the cut, not by an assumption of what is a pocket versus a boss.

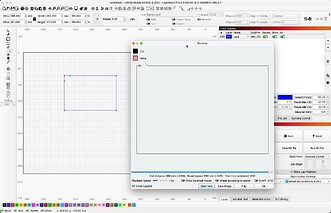

Yes. The example I showed is set to 90º Arc for the Outside and -90º for the inside. Below I have changed that angle to 45º and -45º respectively.

-Didn’t change angle, changed direction of the vector.

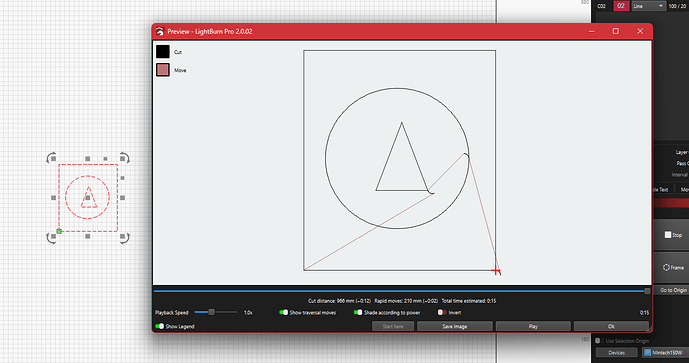

LB is ASSUMING that I’m trying to cut out a circle. Not trying to cut a hole.

Is there any way to change this behavior so that LB ALWAYS treats positive angle leads as coming in from one side, and negative angles as the opposite side in reference to the direction of the vector instead of assuming characteristics of a shape?

Positive angle numbers are for outside lead-ins, and negative angle numbers produce the lead-in from the inside of the shape.

Rick..

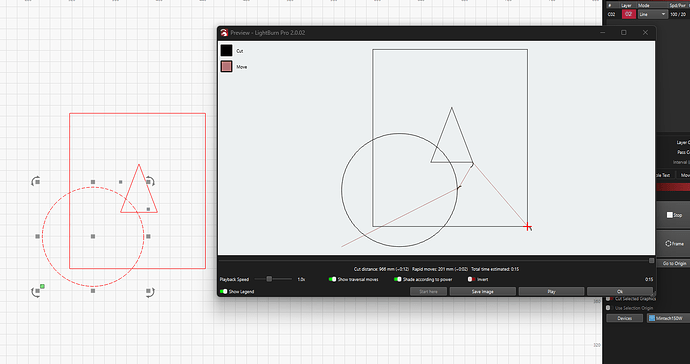

But it’s assuming that cut is a positive not a negative.

In the case of nested shapes it flips direction.

In the case of intersecting cuts… it assumes everything is a positive and comes at it from the outside.

For our manufacturing workflow we need more granular control. We need LightBurn to not make assumptions when shapes/contours/curves nest within each other, otherwise our layer count blows up and we need to start “managing them” as an intermediary step in our software chain.

So is there a way to disable this assumption, and let it rely SOLELY on the direction of the vector start for which side to offset to more like a traditional CAM workflow?

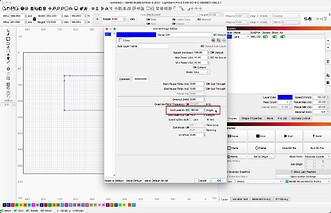

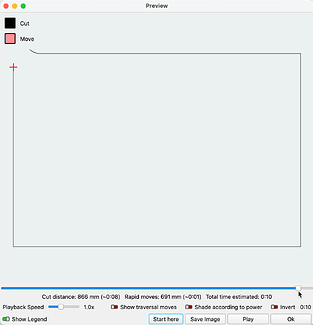

Thank you for this feedback. Currently there is no way to disable it. I will raise it with the team for further discussion. ![]()

OK thanks for confirming.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.