First time user of any laser whatsoever - NOOB ALERT- Our veterans organisation has just purchased a VEVOR 50W CO2 Laser Engraver to enhance our leather work classes. We are trying really hard to figure out the best settings to cut and engrave leather. Everything is trial and mainly ERROR at this point. Can anyone help us with some tips on setting the speeds, power, passes, bed height etc. Infact, any hints with regards to using this machine on leather would be very helpful. We feel like we are tip-toeing through a minefield blind folded lol ![]()

I know that feeling… I don’t do leather, I dislike the smell of burning flesh…

I will try to get you headed in the right direction… There are others here that do leather, they can give you a better handle on how they do it.

Anytime you start with a new material, you need to test the laser on it to see how it reacts… Even two different batches from the same people will vary.

Lightburn has a materials test in the laser tools menu that will create test blocks for you.

Laser Everything has a wonderful video with clear graphics on how to set the dpi/lpi for any laser or material… I suggest you spend a few… you will use these settings for everything except cutting. I know it’s for photo engraving…

It should be very enlightening for a new user… he does it on a fiber, but the type doesn’t matter…

When I have new material to cut, I draw a line and just run it across the material… if it doesn’t cut through I bump the power or lower the speed.

Hang in there and maybe someone doing this can give you a ball park of some kind… Unfortunately, most of lasing is like this… setting don’t just work, each machine is a bit different…

Watch the video…

![]()

Good on ya Jack, thanks mate!

This will go on for years.

Experience is often the best education. I’m sure you have already spent a great deal of time on YouTube, but I know there are many people who are lasering leather… I’ve watched a few videos, but never tried leather myself yet. There are some great resources here as well. Jack (above) is certainly one of them.

You’ll get there, and you’ll have a blast doing it.

At least I have.

Jim

cheers Jim

If you have not heard of Russ Sadler on YouTube- do a search for SarBarMultimedia, he has 200+ videos on his learning journey with several types of lasers. One tip he gave about engraving leather that really helped me was to change the engraving filled area to bitmap, then use some imaging method like Jarvis in the settings for the image engrave. It doesn’t burn a solid, as an engrave would, but if the setting of speed/power are right it still makes a good image without so much smell/char/smoke.

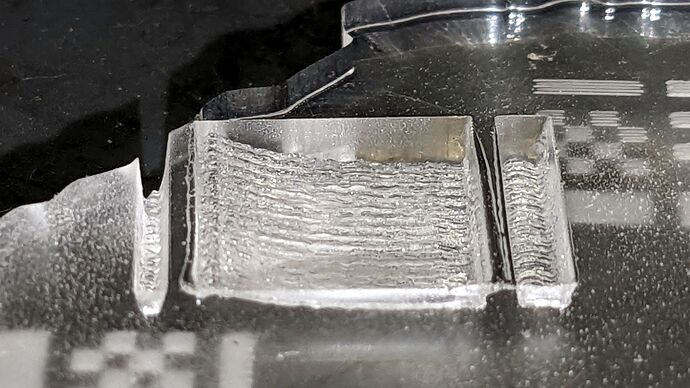

I just finished the other night with a recent video in his series regarding the same strategy for both Cast Acrylic and Extruded Acrylic. The use of a dithered bitmap prevents the beam from being a constant burn, and gives much more flexibility in the results than just speed or power settings. His results in that video speak for themselves:

Jim

Might be better for engraving but it cuts like ![]() relatively speaking…

relatively speaking…

One of the cutting places gave me a bunch, at least to me, part of it was cast and part of it was extruded… Could never get as good of a clean cut with the cast…

If you run with just power and not dither, it’s a CW (constant wave) output with no variation… the damage is only consistent heat… any kind of dither works (helps)… makes it more uneven or more easily visible.

I think @ednisley did some with the grayscale option… maybe he has a photo handy…

He can also advise if it was cast or extruded…

![]()

That was a side effect of something else, but it did show the effect of varying the laser power on the fly:

Which was scrap acrylic of unknown provenance, but its age suggests it was cast, because extruding was a later thing. I think, anyway.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.