Folks,

On my journey through laser engraving and cutting adventures I got to the point where I would like to know and explore how practical to pursue better optics (lens) for given laser diode.

It is obvious that precision of burning and cutting and specific temperature at the light spot are functions of not only power but also how good light is focused.

With few modules I got - all got very different looking spot: One is square, one is looking like Gaussian spot and one does not focus better than 1:3 oval, though spot still small. All appeared to produce responsible burn, but I can imagine that with tight spot - results can be improved, temperature raised, ceramic fused, TiO2 crystallized to darker chunks and so on.

I focus with USB microscope, at max illumination and max zoom, to reduce blooming. Generally I zoon till spot is between 1/2 an 1/3 of the screed vertical resolution. I’m not relying on my eyes, though I can say that when I check my eye focusing - it is pretty close to one with microscope.

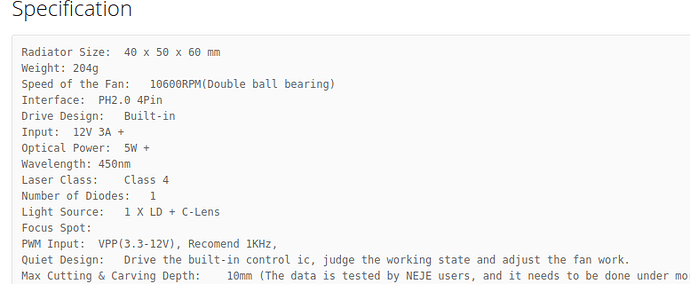

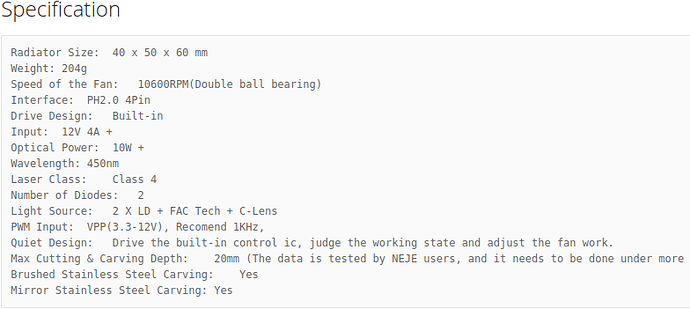

Laser modules themself have very different specs for the spot, if specified at all.

Here is interesting info about laser lenses, and some are matching descriptions on Amazon.

Now I’m trying to find some replacement lenses from Amazon and most if not all appeared to be specified to have M9x0.5 thread. Modules I have are M10 and M12 (I suspect both are x0.5mm step).

The questions are:

What is the reasonable spot size?

Is it reasonable to pursue smaller spot?

How far (smaller) it can be improved? Practically.

What is the common thread size? What are the range of threads?

Is there a good source for replacement lenses? If Amazon - what item number(s)?

It appeared that higher power lenses are fixed focus. Why?

Many specified for distance of 20-23mm. I can imagine keeping lens farther will keep it cleaner longer. IR lasers are essentially are straight beams, I think. So Why optimal is less than 1"?

Anybody got improved results by replacing the lens?