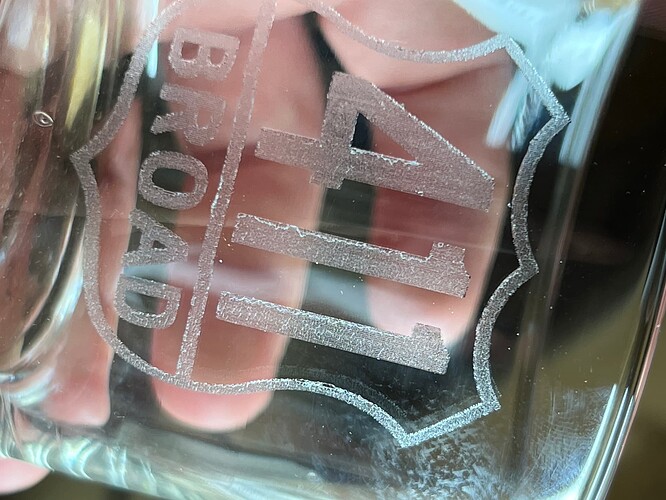

Iv looked through some of the threads and watched a ton of videos and maybe I’m just approaching this wrong but I cannot get this right. Im engraving off of an svg file and my line lpi is like 254, iv tried high power high speed and now im lower power(20%) and at 22ips for my most recent attempt which has not yielded my favorite results but for sure less chip out. I’m also using a thin lay of dawn and no air

What are you using for a coating?

Looks like it’s powering off some of the glass.

I had a glass guy advise me to use steel wool on glass to ensure all the shards come loose here, not in someones hand or finger.

![]()

Just the dawn, if I’m going to just knock it loose should I just up the power to get a better look before I do it? When marketing these is that the way people do it before they sell them?

Me too😂 I’m guessing UV is the way? Lol

I shot my wad on my fiber.. Unless I win the lottery, no uv for me.

![]()

Same here, currently just wouldn’t make sense business wise, got too much other equipment I need😩

Have you tried putting down a layer of wet newspaper and etching that on top of the glass? I’ve heard that gives some decent results, but cant recall where.

CO2 will cause chipping like that when just blasted without any surface cover, in my experience.

You are using a diode laser, right? it’s simply the wrong tool. You can make it work, but it will take much testing. It doesn’t look too bad, just continue. Try a different coating maybe. And it can also be the material itself, maybe try something different. There are many types of glass.

I haven’t but I will give it a go!

I have a 90W CO2, honestly I’m beginning to agree with the material thing. I ordered these from JDS but I was looking back on a glass I picked up from dollar tree and it looks great compared to these and I wanna say I used the same settings on them. So maybe this glass is more suitable for a UV laser but I’m gonna run some more test.

And we’d know that because?

If you don’t tell us and don’t update your profile to show a machine type of some kind, you’re really wasting everyone time trying to help you.

I looked at your profile and it only listed led types, not co2.

Maybe my wife will buy me a new UV machine, since my co2 only works with low cost glassware… … dreaming .

![]()

@jkwilborn My apologies, I went to update it when I first got it and upgraded my license and I didn’t find it and then it slipped my mind. I fixed it though

No perspiration, we’ll live, but it creates a lot of unneeded traffic.

![]()

A stiff brush and soapy water works in some cases too

Try masking tape, I have had good results burning through a masking.

I have had good success using OL6X100ROLL - 6" x 100’ Blazer Orange Laser Mask from JDS

Copied from my Reddit post on this very topic:

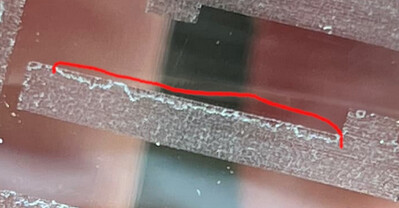

3mm’s off of the material, versus the standard focus using my measuring tool. Defocusing means:

• no expensive & messy films • no detergents in your machine • perfect & consistent results every single time. And use a wet/dry sanding sponge to clear micro shards. [I use] 1400 grit [under warm running water]. USE A MASK AND GOOD GLOVES FOR YOUR SAFETY PLEASE! Last step is just a quick wipe down with a good glass cleaner.

…and Jkwilborn asked me over there "Can you explain the advantage of de-focusing towards the material?

I know the math for lenses and once your outside of the dof the spot size is the same no matter which direction you move away from focus.

I’m not hooking up how this works.

I have a friend that is a glass artisan and he advised I use steel wool to de-shard engraved glass. I know you have to get rid of it, or someone will end up with it in their hand or finger. It’s never appeared to scratch the glass.

Thanks for the post, it’s appreciated. ![]() "

"

To which I replied: "Sure! So, you’re correct, you could go either way and get the same results. Defocusing toward, however, cuts the major math out of the equation ([eliminating] risk of error). It’s the easiest way to find that right expansion of the dot size that affects the glass consistently, and is easily repeatable across machine types with the least amount of fuss.

Video and photos are located at https://www.reddit.com/r/lasercutting/comments/1mv6kvg/just_a_reminder_that_all_you_need_to_do_in_order/?utm_source=share&utm_medium=web3x&utm_name=web3xcss&utm_term=1&utm_content=share_button

Hope this helps!