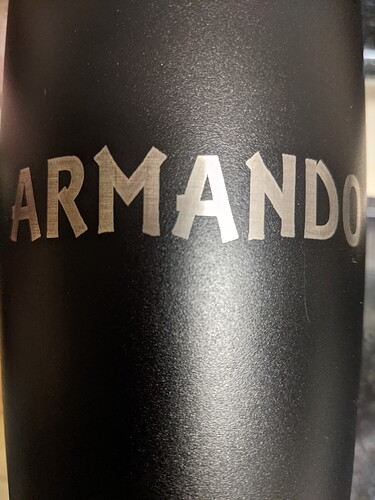

Anyone got any ideas? Drops enough to be noticable. I have tried different fonts and doesn’t help.

Picture would be beneficial. We really need to be able to these types of failures…

Do you mind posting the .lbrn2 file?

The problem is this could be ‘good’ artwork, so I can’t really tell what it’s supposed to look like, if you follow me… I can probably tell from the .lbrn2 file.

WSQ9 Tumbler Armando.lbrn2 (39.0 KB)

Lettering is just typed straight in using lightburn font.

Thanks

It looks like you are scanning the image ‘around’ the cup. So you cup is spinning back and forth. Lots of times the cup will ‘slip’.

Try engraving with the major movement across the X axis.

Move the mug the least amount that you can. Here is a video, move up to the 2:30 mark. Is that how you are engraving?

You might have to change some acceleration values.

Before changing any controller make sure to go to ‘Edit → Machine Settings’ and ‘save’ the current configuration as a ‘default factory’ configuration.

Is your rotary a ‘wheel’ or ‘chuck’ type?

I am moving along the X axis " side to side" currently, rolling the cup as little as possible. I.E. one vertical line at a time If you look at it standing up. Design on other side comes out great, it is just text that is the issue. I have an OMTech wheel type. Not able to get to video?

This doesn’t look ‘vertical’ to me… but if you say so…

It is, you are seeing the grain in the stainless steel. I’m perplexed it usally drops the letter down some times or they come out narrower in the middle. Seems to roll smoothly and design is correct for everything else. Just text that gets goofy.

Just to make sure, laser head is traveling for top to bottom of letter, not side to side.

I couldn’t do much with the supplied file as I’m missing the fonts…

There must be something missing… I can’t see anything that is amiss.

It is highly unlikely that 1/2 the image will work and the other won’t…

Turns out it was mechanical misalignment in the rotary device itself. Tinkering with alignment but have got drift down to less than a mm.

Great! Should always check out the basic hardware, like is it tight, are connectors snug… etc…

Take care, have fun

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.