I have one of those inexpensive Chinese 3018 where the gantry is fixed and the table moves . I watched the camera videos and setup instructions. My concern is I built an enclosure for my laser setup mainly to be able to exhaust the fumes . I checked the measurements

For camera and I have sufficient space to mount the camera .

But when laser is in home position most of the laser bed wouldn’t be visible to camera . I could move the bed so most is visible to camera .

Is this a good solution? Or should. Just stay away from camera with this type laser system??

You’ll likely have issues with it because:

-

You really need limit switches for the camera to work well - the camera uses absolute positioning.

-

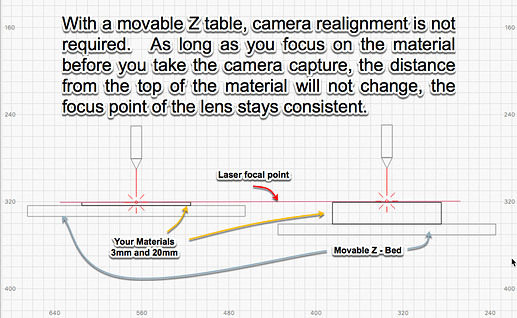

The camera needs to be mounted at a fixed distance from the top of the material, or you need to calibrate for each new material height - this means having a Z table works best.

The camera system can handle mounting at weird angles just fine, as long as there is enough resolution, but the other two are quite important.

I have limit switches installed and this makes the system home . But I understand z table for focus. I typically use material 1/8" to 1.0".

How important is the thickness of material for the camera to help me position stock to be cut or engraved?? What happens if I set up camera say for 1/8" plywood and then switch to 1" stock without making any camera adjustments. I would only be adjusting the focus for my laser?

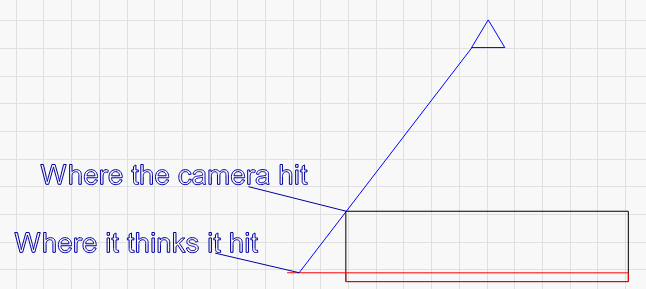

If you put 1" stock in the machine after calibrating for 1/8", it would make a decent difference, and it would be worse for cameras with a wider field of view, and the further off center you used:

If the black shape is 1" thick, and the red shape is 1/8", the blue line is a ‘line of sight’ from the camera to the material. This is exaggerated, but that’s the effect.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.