So, for the diode user that thinks their machine is defective, it’s not. Go to edit, go to settings and switch from co2 to diode. Ikier 48w max pro is a wonderful machine, though my only complaint, harness to short, and had to apply thin 3m tape on guide cover then screw it down to stop the resonating.

I think that is mentioned in nearly all the guides. Though, if you are talking about speed unit settings, it’s absolutely fine to use CO2 settings, it won’t change your laser performance, you just have to use different values then.

So, it will be EASIER to use diode settings, that’s all ![]()

I know what I went through, it was a learning experience, it does change the performance quite a bit. All settings were way off in value. Not to mention I figure things out. just like people, and their intent behind a reply. not saying you’re that guy, but you never know now a days.

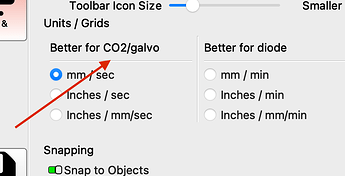

Only for clarification, is it this setting that is discussed about?

… If this is this setting then it will be equivalent to the fact that in one’s car tachometer stands km/h instead of m/h or vice versa. The scale is different but the horses run just as fast.

Stephen, thanks for the info. Can you expand on your experiences troubleshooting this machine?

I have the 24W and I believe I’ve used the “best for diode” settings since day 1. The Software Settings menu Bernd attached above…this is to what you’re referring?

I’d also love to hear more about this 3M tape you’re using. I have an annoying resonance when engraving at about 7000mm/min. Some of it does come from the gantry cover. Some seems to come from inside the RH Y axis extrusion (my machine has the 750mm extensions).

I’ve read reports that setting Lightburn units to inches can cause the autofocus routine to break. I always run in metric. Have you found this to be the case?

As Bernd mentioned, it does not. It’s the same, you just need to convert it. You can run your laser at 10 mm/s or 600 mm/min. The same outcome, no difference. As I said, it’s just EASIER to use mm/min with a diode laser since that’s the common unit (most examples you see are in mm/min), and you need to do fewer conversions.

YEP! that’s the one. It wouldn’t engrave mdf it printed not engrave

mm, been using mm still using mm, telling you it made a huge difference. When no matter the setting you use and still can’t cut mdf board. But now cuts in one pass. Zero burning, just straight through.

Basically removed the 4 screws out of the laser guide and removed the cover, then cut very thin strips of 3m tape in the groves that a touching when it connects then I replaced the screws. But there is also that one sided sticky felt that could be used. Yep, totally metric. I’m using the 24w 48w max pro, wonderful machine.

Thanks. Next time I do a deep cleaning, or move the enclosure, I had planned on digging deeper into my Y axis resonance. It’s on the far side of the enclosure and hard to work on without pulling the box and really “getting into it”. It’s easy to avoid by changing speed so I haven’t wanted to disturb what’s working for no other reason.

I think we don’t have to go on with this discussion, but if it made a difference for you, there is something else you changed / did not convert correctly. mm/s and mm/min can be exchanged at every time, as long as you do the conversion correctly, there is no physical difference (impossible). You can only have a conversion issue, that did not translate settings correctly (to be honest, this can happen from time to time with LB).

I can stand witness to the fact the GRBL config and controller in this machine can sometimes be a little odd. I know LB doesn’t read the controller settings correctly for simulation/preview. They MUST be manually edited. I suspect there are some other oddities hiding where I haven’t looked or don’t know enough to see.

mmmmmm, so you are wrong you weren’t here so your limited view of what you know and what I found to be is irrelevant do have a goodnight this post is now dead to me. Maybe you should translate your view on how you talk down to people.

@Stenok

I think it’s a pity that you see it this way. Here it is not “talked down” to people, people try to help and they spend their time on it. Why don’t you just accept the explanations you’ve gained from people who are likely to have more experience with Lightburn as you have? There are 3 forum members (me included) who have said the same thing about your question and you still mean they are all wrong? With that attitude, it will not be easy for you to get help or participate in technical discussions here in this forum.

(it’s only my private opinion to that)

But they too were wrong, so your words fall short, I now see it as nit picking to make yourself look better. No, like I said were you here, you all make it about totally what was not the issue. inch mm min, must be your linear thought process that won’t let go of a discussion when you think you correct. when you didn’t even observe the situation always quick to judge though man I wouldn’t want the karma door you opened. ( my opinion) but hey enjoy the universe it never misses. Have the day you deserve. good bye.

No word whatsoever was meant to be rude or anything. As Bernd said, we are here to help. Nobody said that you are lying or something. We just said that your assumption is wrong. That’s all. We do not doubt that you had different results in your tests. All we are saying is that this was NOT caused by the setting you are suspecting. There has been something different (maybe even a bug in LB) that caused your issue.

But how can you help, if you’re wrong come over I’ll show you exactly unless you see it for yourself you’ll never stop for the fact always trying to be right. News flash you’re not perfect. Always trying to one up just like the star’s. All other setting were the same. And they even read up on it so no there was no help at all. I wouldn’t expect anyone to understand my mind. But the narrow linear shell you have is most definitely not it. But do have a good day.

I’m going to pause this thread.

You’re mostly right. I think I know what you’re saying. This catches more people than most would expect. We have several tools for manufacturers to handle speed settings and simplify this step. It’s regrettably underused.

It’s easy to overlook the 60x speed difference between mm/second and mm/minute and it’s one of the key diagnostic points when helping new users get started.

200 speed is like 200 water; without the units of measure it’s nonsense… but I often find myself talking folks out of ‘unitless speed’.

To make matters worse. GRBL controllers handle mm/minute by design. It’s not a standard metric unit for speed where m/s and cm/s are.

To further conflate the matter, the maximum speed allowed by the max speed (or max Rate) settings in the GRBL Controller (also mm/minute in the Firmware) reduces the speed (at the allowed acceleration rates in mm/sec^2) toward the maximum speed when an overspeed condition is requested.

To compensate for the unmet speed commanded, and to still put the expected energy into the workpiece, the controller reduces the power of the laser, by the ratio of the speed of the actual motion to the speed of the requested motion. It’s all too easy to get the GRBL controller into a weird state where it only engraves at 1/4 to 1/10th power… until it slows down to change direction. When it starts to slow down to change direction, the motion planner sets out to reduce power but it does so as the selected speed ratio brings the power up causing burnt outer edges where slowing is intended.

Most CO2 Lasers have a different controller, are 10 times the cost and are built stiffer to accelerate and decelerate more aggressively. DSP Controllers, seen in most CO2 Lasers, require an upgraded LightBurn Licence (or our standard Fully Functional Free Trial).

Recently GRBL controllers have gotten fast enough to be able to control and clock stepper motor pulses at the faster rates to accurately control a CO2 Laser.

You can operate LightBurn in any units of measured speed shown in that menu.

We’ve asked for an Easter Egg in this menu, containing nonsensical units like Bananas per Dramatic Pause, Furlongs per Fortnight and Half-giraffes per Limerick but the boss won’t go for it.

You can use the GRBL controlled laser diode or a GRBL controlled CO2 laser in either mm/minute or mm/second IF you multiply the selected speed in mm/minute times (1 minute/ 60 seconds). 60 seconds and one minute are the same, so it’s just multiplying by 1 and the actual speed doesn’t change but this is the slick way to change units around.

180 mm/minute * 1 minute/60 seconds = 180 mm/ 60 seconds = 3 mm/second.

LightBurn will convert the units to whatever the controller needs and control it on its terms. LightBurn also offers you back the working units that you’ve chosen to work in. This is handy for folks who work with older plans in imperial units.

The default for units of speed is defaulted to a setting that would move the laser at the fastest actual (metric) speed when the units are overlooked. This is intended to prevent the fire risk presented by a new user commanding their new (Likely CO2 laser) to engrave at 60 times slower than recommended - with all the excitement that would entail.

With typical CO2 lasers ranging from 30W to 130W (and CO2 lasers producing invisible long infrared energy) you can probably see why the default in LightBurn is set the way it is.

I hope this offers some clarity and some insight into what other folks were attempting to offer here.