Ok,

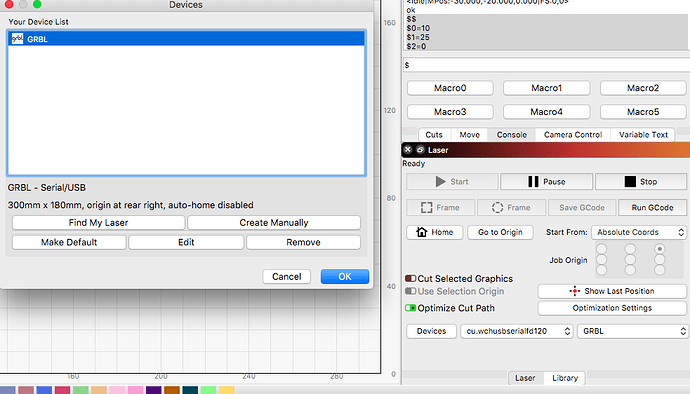

I powered everything up and when I click on Get Position, it tells me x0 y0. The machine is currently at what I believe to be the laser position farthest back left.

So you say enter G92 x0 y0…i got ok. and if i click Get Position I still get 0,0. So im guess the button Get Position on lightburn and g92 x0y0 do the same thing in this case.

You said set $10=0…i got ok again.

So i decided to use the location jog button and click in the center of the canvas…one of the motors made a loud noise, the x axis motor moved to what looks to be the middle, but the y axis motor didnt move at all, i think that was the one making the loud noise.

Without having to click on it, Position seems to be x150 y90. And if I click on Get Position it gives me that same point. But something happened with the y motor.

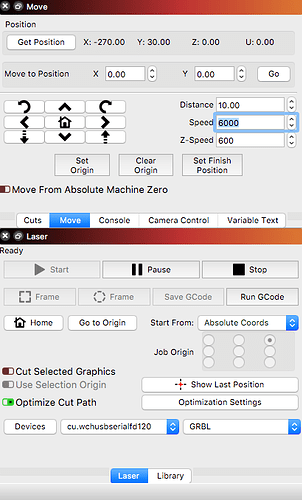

I went to the individual move buttons and clicked on

X- and got spindle moving left & Get Position is x140 & y90

X+ back to x150 and y90

Y- bed moved towards me x150 & y80

Y+ bed moved back into place, x150 y80.

Clicked on Canvas 40,40 and the laser is now pointing at back left corner almost, Get Position 40,40

Clicked on Canvas 140,40 and the bed ran over the limit…so i have an issue with the y axis still. The Get Position reads x40, y140.

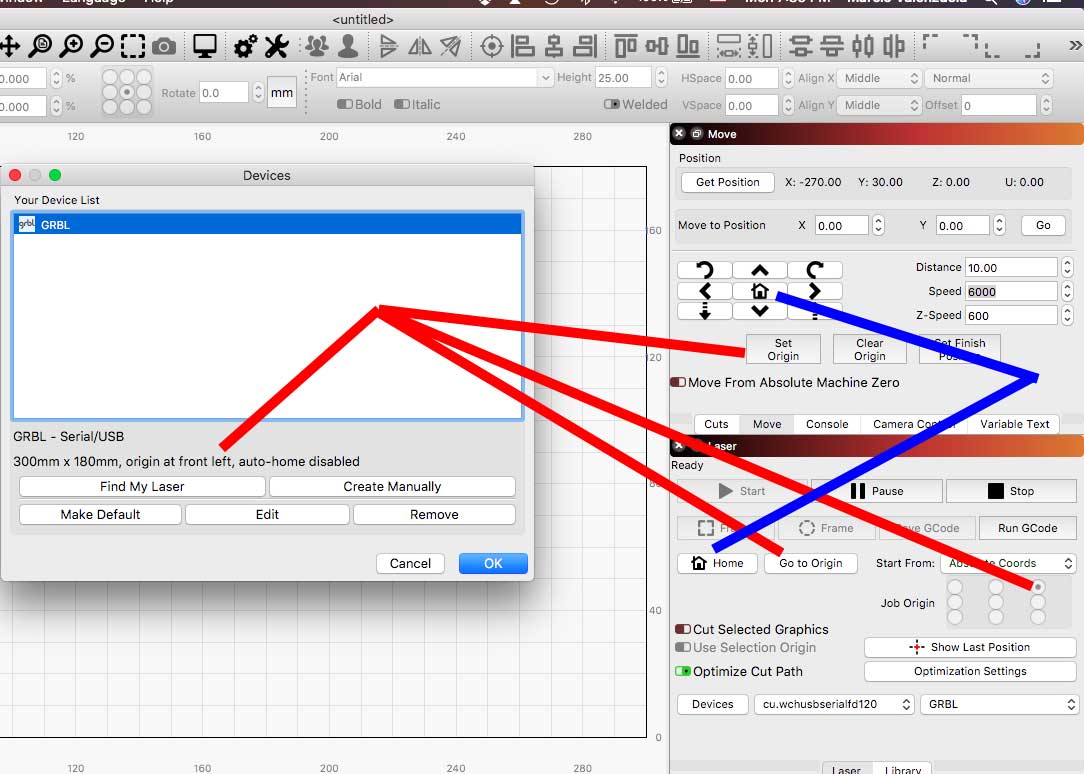

$$ gives me $130=180 & $131=300.

Clicked on Canvas 40,40 and it moved to the back left again and Get Position is 40,40.

Clicked on Canvas 40,240 and it moved across to the right side, Get Position x240, 40.

Clicked on Canvas 240,100 and it moved backwards w/o overrun, Get Position x240, y101.

So Im guessing I need to reset my 0,0 closer to the edge of the platform? I just eye-balled it the first time plus a few mms for caution.

How should I make sure where I want to set 0,0 as machine origin is exactly the corner of my platform?

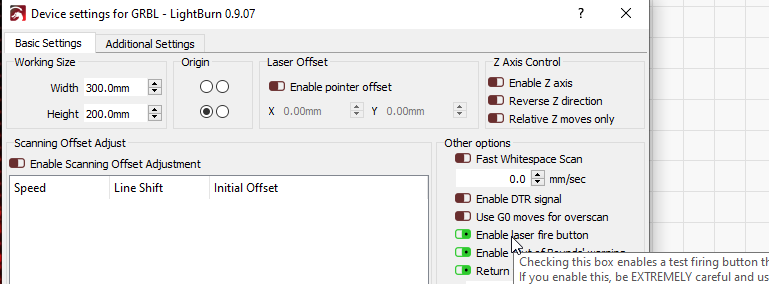

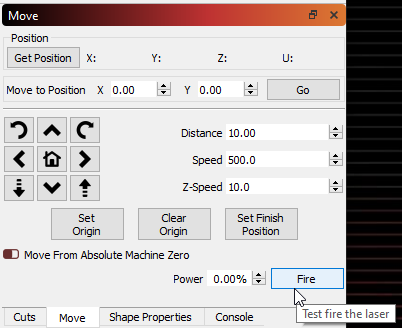

I decided to type G0 x0 y0 as the doc referenced above says…and it went to the back left, but it doesnt seem to be where I set it. Oh, how do I turn on the laser from lightburn? I didnt find it in those docs. I mean turn it on but just a bit so i can see where on the platform its actually pointing at.

At present, after g0x0y0, it moved to what looks about 10mm from the left edge and 30mm from the back edge.

![]()