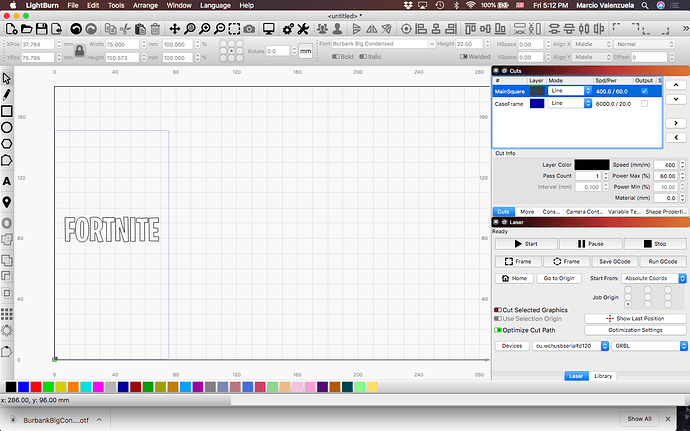

The ‘origin at front left’ in the Devices window is talking about the physical origin of your machine, IE, where your laser system believes X0, Y0 is.

The Home button you highlighted tells your laser to run its homing cycle (if enabled) to seek out the limit switches that it uses to determine its location. These are often at the origin, but not required to be. The common K40, for example, has the limit switches at the rear-left of the machine, but the origin is front-left. It knows how big the working area is, so after finding the rear-left, it knows “oh - I’m at X0 Y200, so X0 Y0 is 200 mm down”.

The “Go to Origin” and “Set Origin” buttons are referring to the user/job origin, not the machine origin. This is where I meant that the CNC and laser terminology get confusing. The Job Origin / User Origin is where the laser head position is relative to your design when the job starts, and we cover that here: https://github.com/LightBurnSoftware/Documentation/blob/master/CoordinatesOrigin.md#coordinates-and-job-origin

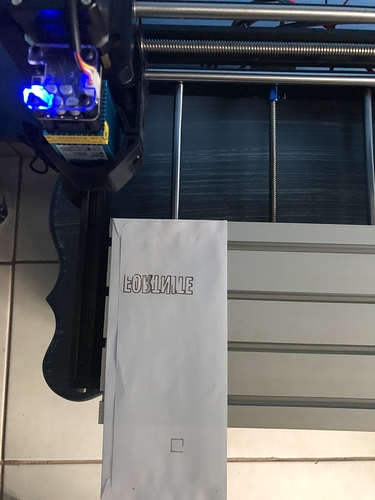

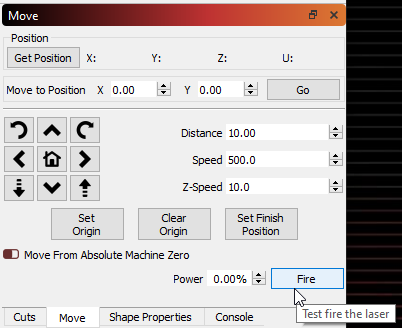

With your machine at the bottom left, if you type:

G92 X0 Y0

In the console and press enter, it should reset the current position of the machine to 0,0, so the Get Positions button now reports the correct values.

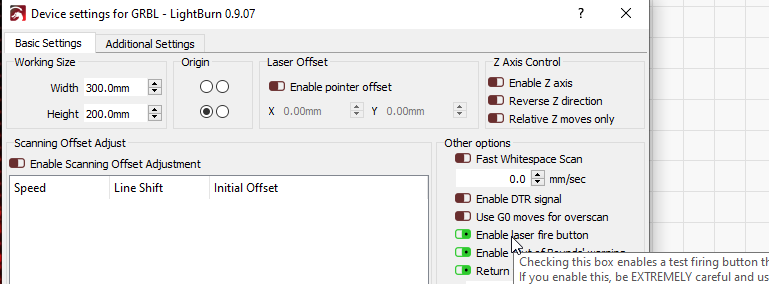

You should also set:

$10=0

The $10 setting controls the way coordinates are reported by your machine to LightBurn.

Most of these are covered here: https://github.com/LightBurnSoftware/Documentation/blob/master/CommonGrblSetups.md#common-grbl-setups

. I can still use lightburn right?

. I can still use lightburn right?