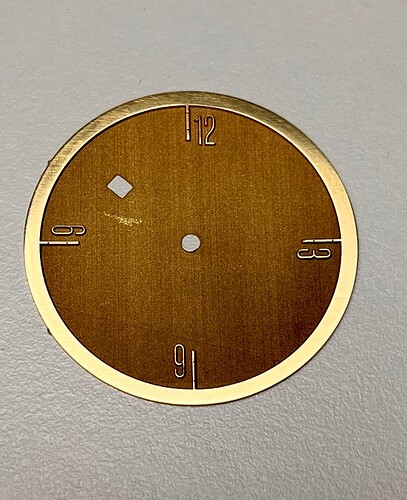

we have a cloudray 50W JPT fiber laser. It is a fantastic tool but we have many small challenges. The intended use is for creating watch faces in 0.5mm brass. I have spent a full weekend calibrating, and following all instructions carefully. Saturday I had great success engraving to 0.25mm depth with these settings.

1200 mm/sec

80 power

25 frequency

.0100, no crosshatching

we set it at 66 degrees and to autorotate, (we are creating round watch faces and this is to secure we don’t get any stepping in the cutting)

we did 12 passes, then a clean up pass

1500 mm/sec

10 power

20 Frequency

.0250 cross hatch

45 degrees

4 passes.

then we repeat.

worked perfectly and the parts came out super clean…

yesterday we used the same settings and after the first round the laser had burned thru.

after burning thru.

We updated the settings

1600 mm/sec

40 power

25 Khz

.0250 no cross hatch

123 degrees - auto rotate

3 passes

then a very similar clean up

this worked great

is there something we ae doing incorrectly we are certain that the settings we are using are not incorrect from what I have wrote but we get extremely differing results on different days.

this is of course a very big challenge as we have been struggling for weeks with this and have generally felt that it was the LightBurn software, I am at a loss so we are looking for some help?