I can’t imagine anyone “spiking” their leather goods and wearables with these things (they’re pretty sharp)… but these are the ones I ordered on Amazon.

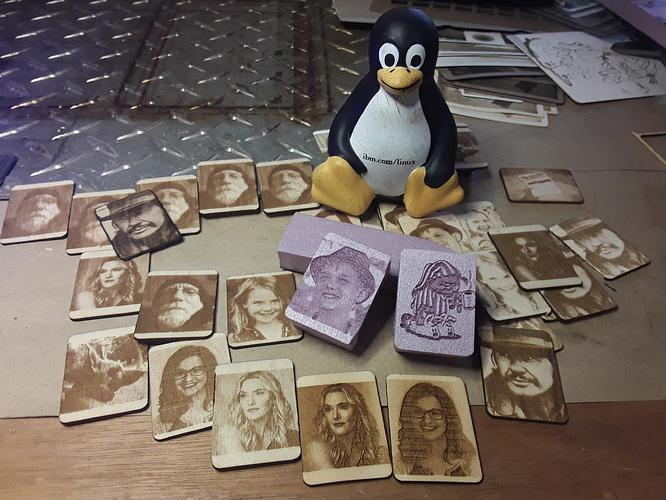

I recognize that the plastic (PLA) wouldn’t stand up to a CO2 laser but I have only 2.5 and 3.5 watt Banggood/Eleksmaker diode lasers… so it works for me. I’m having a blast playing around with small stuff and trying some of the engraved photo techniques @Bulldog is sharing with us… primarily in cereal-box chipboard and craft-sticks right now

I wanna try my hand at the ceramic tile engraving when I get a chance to get out again and get the supplies needed…

– David