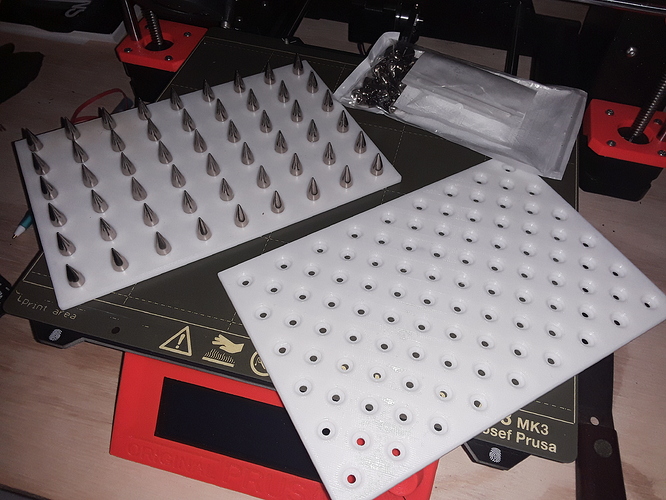

I know they’re two completely different things. I use Inkscape all the time for my design work. I have a big 473 page book on everything Inkscape all dog eared with notes. However this week I want to build a 12” x 18” “Spike Plate” for my laser. I bought a pack of 50 1” spikes with screw bases on eBay. I’m going to cut it out of 1/16 aluminum sheet with a waterjet. I started creating the design in Inkscape and quickly realized its not capable of arranging an array of 1/8” holes the way I want. Since I plan on having a pattern of holes evenly spaced 6 rows high by 8 rows long, I don’t want to place them all by hand. That would be a messy time consuming job. I gave the problem a think. It dawned on me that LightBurn has a array/grid function. I quickly made the 12x18 rectangle to cut with cool rounded corners and placed 48 holes nicely arranged and centered inside it. I saved the whole thing and exported it as an stl file all in about 5 minutes. I couldn’t be happier. As much as I love Inkscape, it just can’t do this one thing. The CAD part of LightBurn is actually turning out to be much better than I originally imagined it to be. I was planning on using Inkscape for design and LightBurn for laser machine control. I’m rethinking that.

Nice! I see you have one more row than I do. I’m jealous. I’ll be cutting mine out soon.

These are small bed-of-nail plates I can use with my 2.5 watt diode lasers. I used Onshape to do the layout – it has very nice circular and linear arraying tools – and create the STL for 3d printing.

Though I’m using Lightburn for many tasks I used to use Inkscape for… IIRC I was able to array (clone?) shapes/lines in Inkscape for rulers that I laser engraved using the JTech laser plugin.

LightBurn is unlikely to ever be great at freehand artistic work, but I’ve always wanted tools for patterning, cleanup, and light design where it makes sense.

I own Vectric Aspire (and had VCarve Pro before that) and I found that I used it more often than anything else when making stuff, because it was really fast at specific kinds of things - I feel like LightBurn is getting close to that too.

In any case, I’m happy you’re happy.

I’ve got the whole Aspire package too and it’s always been my go to for CNC routing. I’ve made some beautiful art with V-Carve. I started with BobCAD years ago and just got tired of how hard it is to use. For 2 dimensional Inkscape has been good.

you can definitely do it with inkscape, the function is named “tiled clones” (edit / clone / create tiled clones)

Would you be so kind as to share a link with us. I’m interested I getting some

Thanx

Sasquatch

Do you use it mostly for engraving ? This setup would not be favorable for larger CO2 lasers for cutting due to the plastic base would be obliterated by the laser beam cutting through.

Very nice design and work by the way.

Sasquatch

I can’t imagine anyone “spiking” their leather goods and wearables with these things (they’re pretty sharp)… but these are the ones I ordered on Amazon.

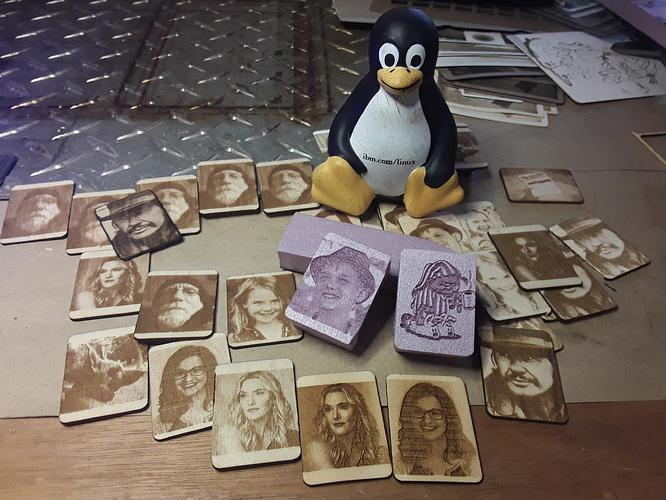

I recognize that the plastic (PLA) wouldn’t stand up to a CO2 laser but I have only 2.5 and 3.5 watt Banggood/Eleksmaker diode lasers… so it works for me. I’m having a blast playing around with small stuff and trying some of the engraved photo techniques @Bulldog is sharing with us… primarily in cereal-box chipboard and craft-sticks right now

I wanna try my hand at the ceramic tile engraving when I get a chance to get out again and get the supplies needed…

– David

My comment was an observation for other readers in our forum who might consider doing the same setup for a non diode setup. I knew that you would know .

Thank you for sharing the link.

Gotcha… ![]()

Looks like I should be taking lessons from @dkj4linux very nice

I think you both should collaborate.

Nay, nay… @Bulldog. I’m a rank beginner at this photo engraving stuff and just trying to come reasonably close to what you’re showing us. I’m not there by any stretch but still seeing my best yet… and looking to improve. Thank you for sharing with us!

key is to document …success and failure…I take a photo copy of engraving…add notes…settings etc…then file…I have files for different substrates I use

Hi Sasquatch, these are what I’m using.

Yep. Inkscape has the Clones function.

Im making my base plate out of 1/16 aluminum sheet. 48 holes spaced every 2” for the spikes.

A retired electrical engineer, I spent 40+ years in industry, working with many engineers and scientists… some incredibly organized (as you obviously are) and others who are some of the most disorganized folks you could ever meet. Sadly, I fall into the latter category… a competent design engineer but hating to document my work. Curiously, after retirement, and letting the kids finally talk me into getting a cellphone a half-dozen years or so ago, I – almost by accident – discovered the phone’s camera functionality (I grew up hating cameras!) was both handy and useful to “document” all the stuff I enjoy messing with. And now, with participation in the several forums I “inhabit”, I find that I’m now documenting/discussing my work FAR BETTER than I ever did professionally! I’m still lacking in the keeping up with my notes/files department… but, at 73 years, I forget lots of stuff and doubt that’ll ever really improve. I’m hoping that by following some of your recipes and trying to replicate some of your work… maybe some of it will stick!