Hi, I bought a fiber laser some time ago because of the increasing number of articles about PCB preparation using such a laser. I spent my vacation (two weeks) thoroughly testing this issue. Ezcad2 is already outdated and has many problems with supported formats, especially with SVG files. So I wanted to switch to Lightburn, which suits me, and I’ve been testing it for a really long time. But so far, I have not been able to prepare a PCB in either bitmap or vector mode in this software. Some parts are constantly burned through, while others are barely touched… So far, Ezcad2 works best for me personally in bitmap mode, going line by line. But I’m fed up with typing everything manually and the 32-bit limitation. That’s why I would like this post to be a kind of bible where we discuss all topics related to galvo and fiber lasers for copper processing in Lightburn. Maybe we can work out a solution or a “PCB” mode for crazy people like me.

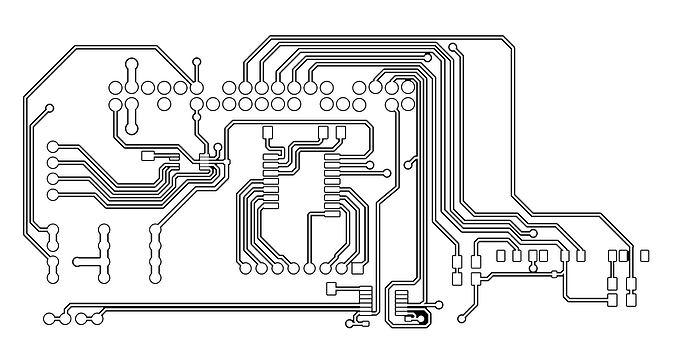

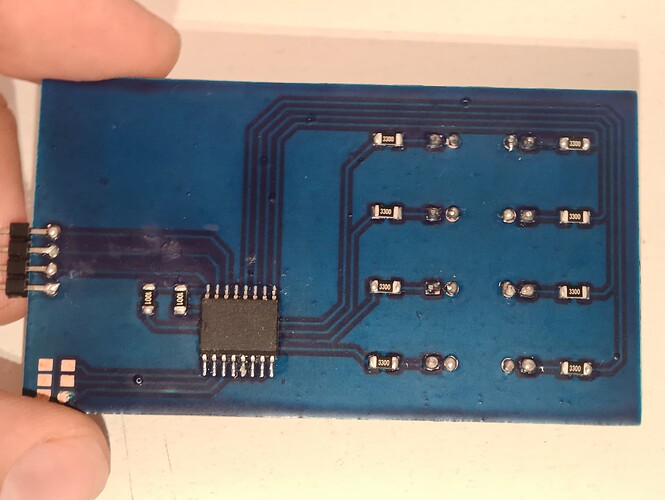

And now for the details. Of course, I don’t know everything about lasers, but I burned through a lot of FR4 laminate in search of a solution. Looking online, most people remove most of the copper from the PCB, but I leave most of the copper for grounding or power supply purposes, so the burning applies to narrow areas between the traces.

In Lightburn, I tried all modes and mixing them. The avalanche fill works best and fastest, but areas where there is more to burn “burn” too quickly compared to the narrow areas between the abrasives. This applies to all modes for SVG files. In bitmap mode, it is difficult for me to choose the settings. If I set it too fast, it only burns the horizontal lines, ignoring the vertical ones. The pulses themselves, even though I set the pulse times, power, and speed the same as in ezcad 2, are too weak, but again, there is burning in the points where there is more to burn. It is also difficult for me to choose the dpi, which is related to the number of lines per inch. If I set it lower and slower, it goes faster, but the small abrasives burn badly and are connected. If I set it higher, the pulses are too weak (I prefer 1200 dpi). Such png files work for ezcad.

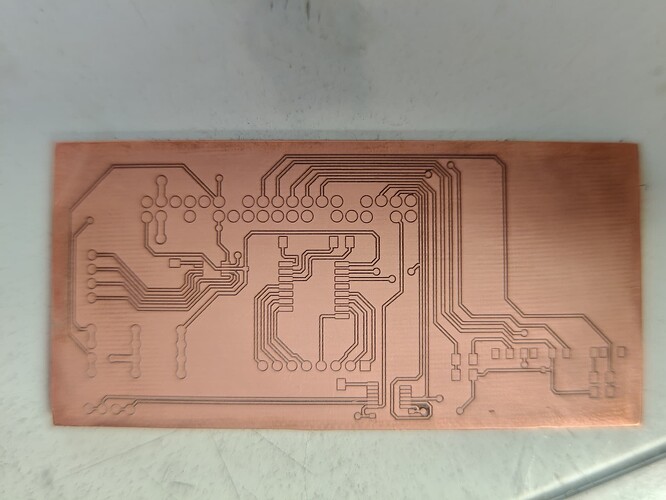

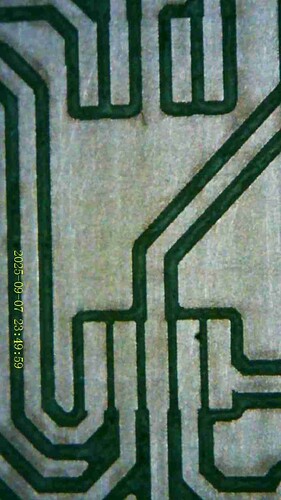

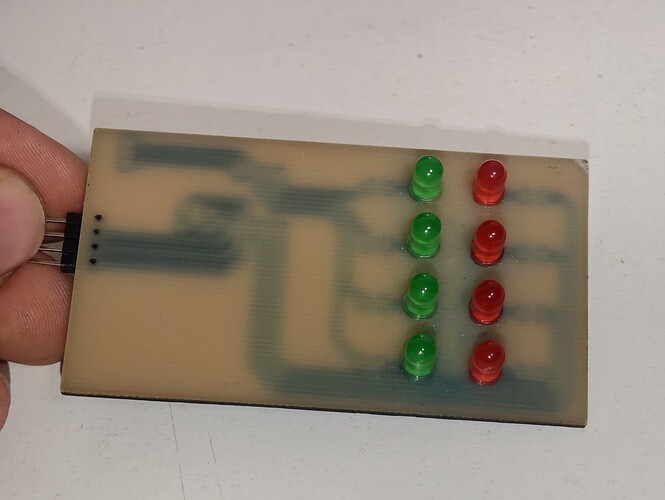

From what I have been able to determine, ezcad 2 in bitmap mode always works in a kind of “grayscale.” It is very slow, but it has a certain advantage: ezcad works line by line, and because I leave the entire background white, it causes the PCB to heat up along the entire line (by a few percent). (this apparently increases copper ablation), and even my pads with a spacing of 0.2 mm and even 0.1 mm come out okay. In addition, the pulses are stronger where they are supposed to be (I am attaching photos of the PCB from ezcad2 in “png” bitmap mode).

Ultimately, I would like Lightburn to allow for such accurate PCB manufacturing that it would no longer be a topic of “interesting facts,” because you are doing a really good job!

Hence my question to the creators and users of Lightburn: could you share your settings or contribute your description/experience to this undoubtedly phenomenal application of these devices for amateur electronics enthusiasts? My laser has an rc1001c scanning head with a 30w Raycus source and an F-210 lens with a working area of 150x150. I have also noticed that the working area is never perfect with copper, and even in my ezcad2 application, the lower areas of the working area seem to be out of focus. I calibrated the lens, the entire column, and tightened the screws with a torque wrench. I even bought a 0.5 cm steel plate to level everything, but it didn’t help (I also changed the lens and rotated it). Of course, this may be due to the scanning angle itself, because in the case of aluminum or black paper, everything is perfect, and the spirit level and caliper show that everything is ideal. Thanks for reading if you made it to the end.

Best regards.