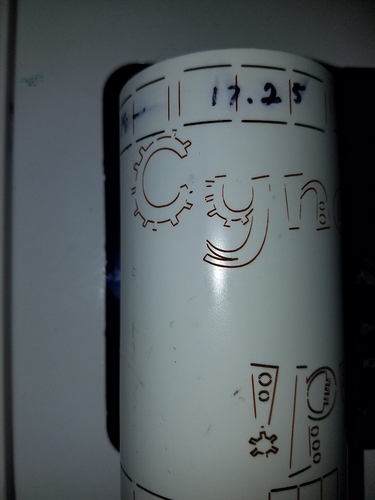

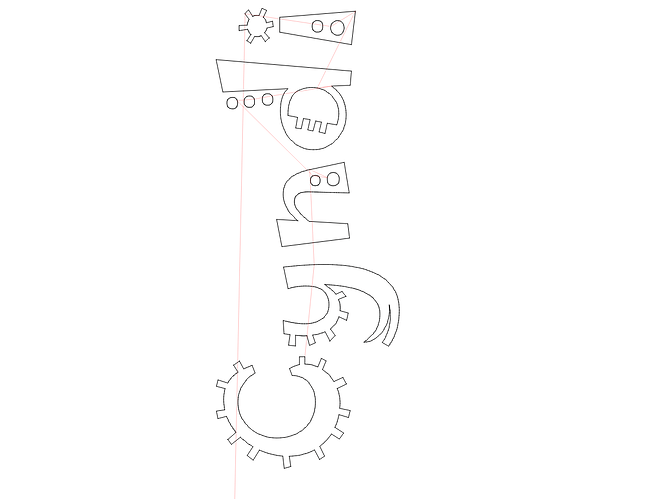

Just installed a C3D laserboard and added a diy rotary and having a few problems I’m hoping to get some tips on. Problem 1 is the burns seem to be hotter (darker) in the A axis rotation than in the X axis in places. Problem 2 is corners aren’t always closed, and problem 3 is it seems the laser is skipping line segments in places. I’ve exported the gcode and at least initially on the first letter that’s missing segments on, the gcode shows it’s enabling power to the laser. I don’t really know what else to look into so hoping someone can point me in the right direction.

Speeding up the A axis, or slowing down the X axis would help with #1.

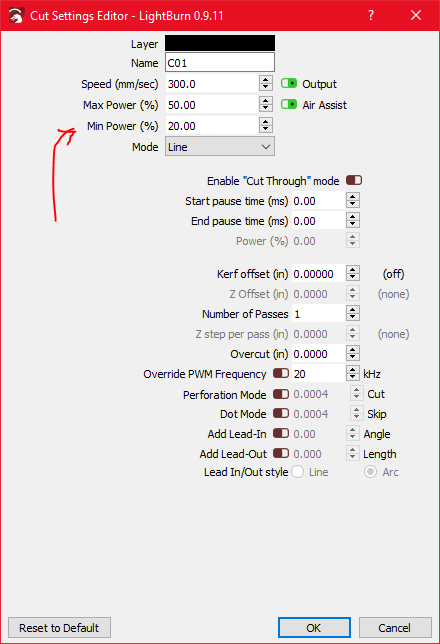

Corners not being closed is likely due to your minimum cut % being too low. The laser slows down in the corners, and as such, decreases power to compensate. Raising your minimum should help.

Can you show an example of which segments it seems to be skipping? Nothing seems super obvious with your pictures.

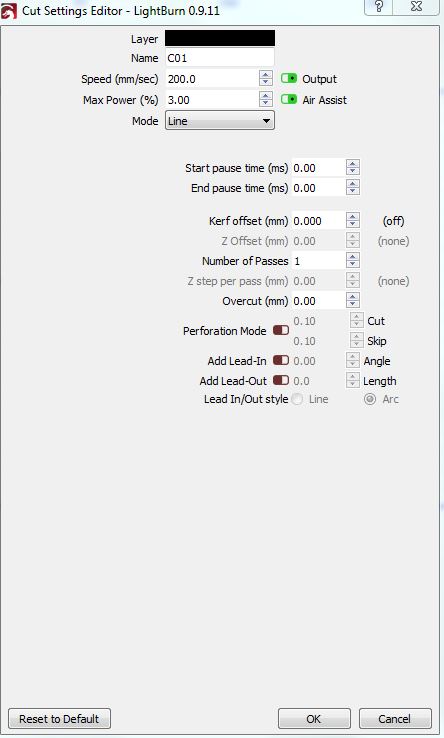

I’ll try changing the speeds to see if that helps the burn. On the minimum cut % this is just line so I don’t have a min power % option, unless your talking about something else? In the pictures in the first post the first picture you can see “Cyn” toward the top and on the bottom a upside down “di”, these were different tests with same results of having missing segments. All letters are supposed to be closed as in the second picture preview. Also at the very top & bottom are a few different test of 3 squares12mm each contacting each other that show both the corner segments missing and the different power being put down.

Yeah, so the top of the i is a pretty short line. My guess is that it wasn’t getting up to full speed, so your power wasn’t up to full power either.

You don’t have a min power?

Also, what material is that you’re burning on? It looks like PVC, and you definitely don’t want to be running your laser along any of that.

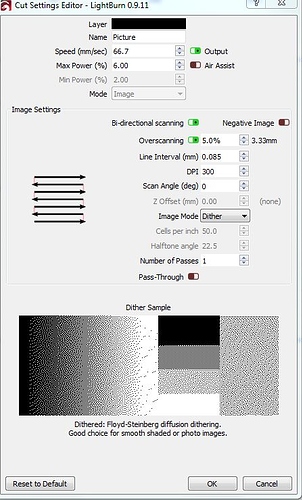

No it only shows Max Power. It seems I can only see Min power with an Image but even then it’s Grayed out and not selectable which is something new I’ll have to chase down. I’m new to the Smothieware and rotary so everything is a learning curve right now.

Yes it’s pvc, I’ve read it’s bad, puts out dangerous gas and leaves bad stuff in the laser. I just installed the C3D laserboard and built the rotary yesterday so my excitement got the better of me and that was all I could find to fit my diy rotary.

It puts out chlorine gas, which will F your lungs up, F your machine up, and everything in between. Very seriously you shouldn’t do that.

If you’re running Smoothieware on the C3D (the default / stock firmware) the minimum power setting is handled by the controller itself, not the software, which is why you don’t get that control.

On the SD card is a file called config.txt. Open that in Notepad and look for a line that says:

laser_module_minimum_power 0.0

The number is from 0 to 1, and is the minimum power value for cutting moves. You should set this to just below the firing threshold of the laser, and you’ll have to find that by trial and error. If you have a 40w laser, a good starting point is 2 to 3 percent, or 0.02 to 0.03. You want the number high enough that it cuts the corners properly, and low enough that it doesn’t fire in the gaps when engraving.

Yea I totally agree with you I was just over anxious. Surprising to me I just spent about 30 min cleaning off surface rust from the new linear rails on the rotary. Surprising to me because I had only run half a dozen or so tests and it definitely mucked up stuff inside the laser. Currently looking for better test material.

Thanks, making the A axis speed the same as the X axis in the config file and changing the laser_module_minimum_power to .02 seems to have fixed the majority of missing segments and open corners. So now I think my only problem is darker burn in the A axis direction. I’m thinking it has to do with gear reduction slowing that axis more than the X possibly?

I wouldn’t try calibrating the laser with PVC either. Whatever you’re planning on engraving the most is what I’d use.

You can’t clean the crap out of your lungs, btw. And with COVID-19 running around, you’re going to need your lungs sans chlorine gas.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.