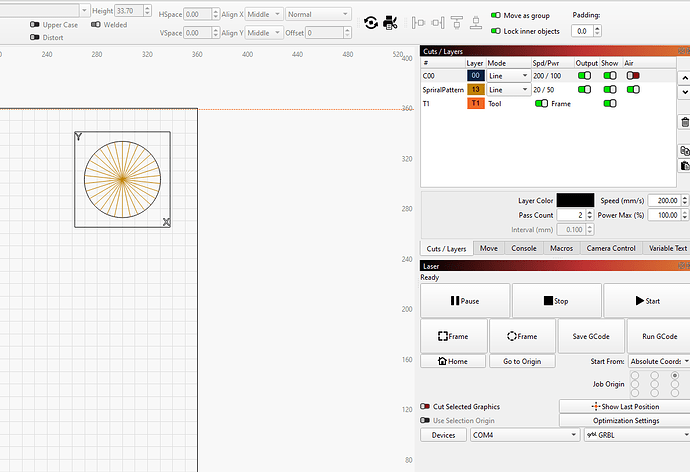

I just set up my laser and have been trying to do test cuts but laser wont cut through 3mm basswood or cardboard. I’ve been playing with the speed/power settings but I just can’t figure it out.

If it was a new machine for me, I would do some power and speed tests with different materials. In LightBurn there are some tests that are quite nice. It gives you a better starting experience when you know your machine well.

Also remember to do a ramp test to check if your focus is optimal.

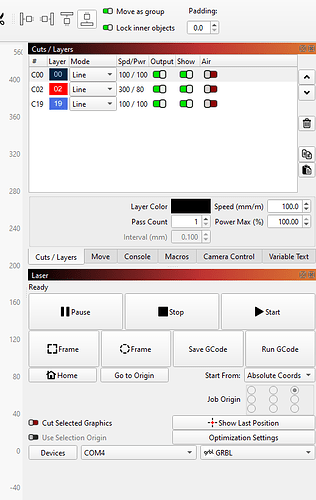

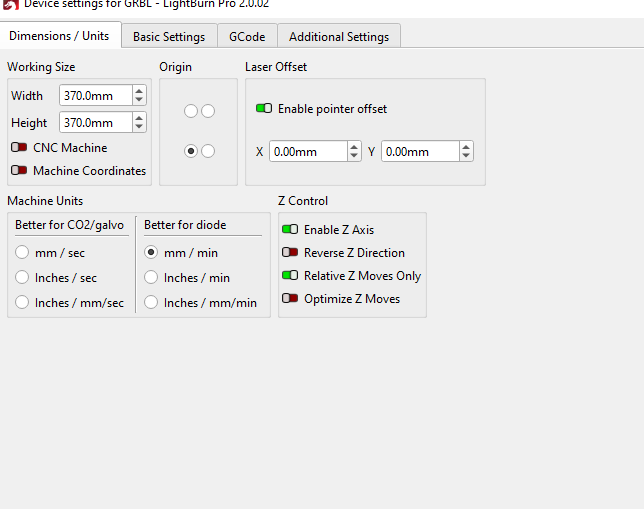

I assume you have it set to mm/m for speed settings.

200mm/m @ 100% power suggests you are cutting in a single pass.

Try 800mm/m @ 80% power and 5 passes.

My 3mm ply cuts through in 3-5 passes depending on when I buy it and what day of the week it is. In other words, it is all over the place, but 5 passes with my 10w gets it every time and charring is minimal.

@bernd.dk is not kidding here.

No, she has set it to mm/s. So that’s most likely the issue. @akulisky You need to change the speed units to mm/min in device settings.

I set it to MM/M, thank you. It still didn’t cut the pattern however. It did engrave it so that’s an improvement.

I did the focus test at the settings lightburn reccomended, I think it was 20% power, and there wasn’t a single mark on the basswood when it was done. I turned it up to 99% and again there wasn’t a single mark.

I tried to cut the pic I have above again after changing to MM/M for speed settings, power at 100%, and speed at 200, but it didn’t cut through, it barely engraved the cut lines. I’m going to keep playing with the power/speed setting and see if anything works. Any advice is appreciated!

I’ve tried all the suggestions and just finished trying it at 200mm/m @ 100% power for 5 passes and it engraved it, but didn’t cut at all. Thanks for your help!

With these parameters and if your laser is in focus, you should be able to cut 3mm balsa wood easily. If not, you should find out if your diode is broken. Can you show a picture of one of your tests?

@bernd.dk is correct, you should be able to start a campfire with that 10w laser.

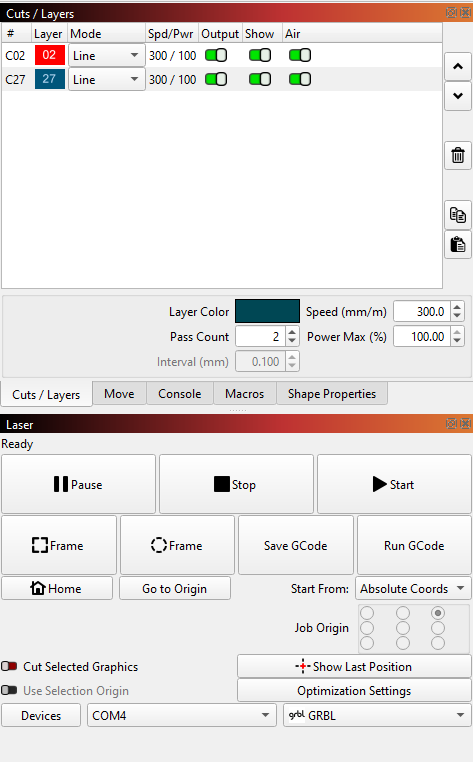

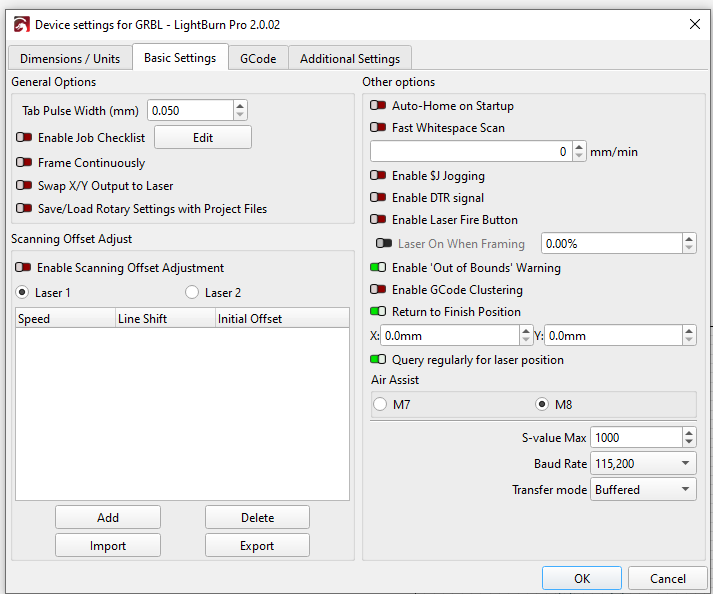

- Your S-value Max should be 1000. (Device Settings window in v1.7, Laser Tools window, Device Settings tab in v2.0)

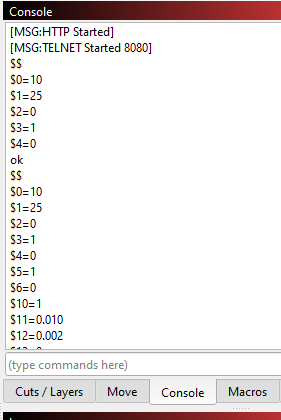

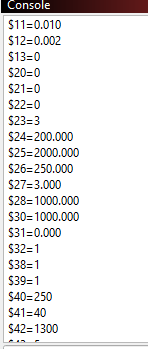

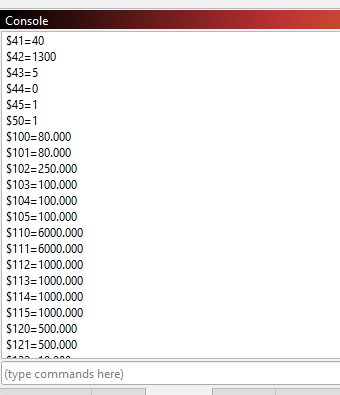

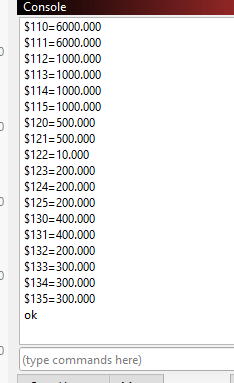

- Your GRBL $30 parameter should match ($30=1000). To view, enter $$ in the Console window to view the parameters.

- Your Device type should be GRBL (only) with no other letters or numbers.

Let us know if any of this solved your “low power” problem.

Thanks for replying! My S-value max = 1000, $30=1000, and the device type is GBRL. I’m going to run a test and post a pic of the results.

Thanks for replying, I attached a pic of a test as well as the settings I had it on. The cut only went about 1mm deep. Thanks!

I am guessing this is a new machine.

I noticed you have Air Assist turned off. Do you have air assist for your machine? It makes a huge difference when cutting.

Cutting in 1 pass is for sales demos. Use 4-5 passes and a higher speed for 3mm Baltic Birch plywood. You will find there is less charing when cutting. Other woods and MDF need even more passes.

Air assist, more passes, and critical focus will get you in business.

It is a new machine. I have an air assist but I haven’t set it up yet. I’ll work on that tonight. Thank you for your reply!

Just to be sure, have you been able to cut through this material before? …and are you sure it’s poplar plywood and not birch?

No, I haven’t been able to cut through it at all. I just got done testing a cut and I’m not sure where to go from here. I cut the pattern at 300 mm/min, at 100% power, and 7 passes. I think it may have gone maybe 1/3 of the way through, but there wasn’t a single mark on the backside.

The listing for the wood says it’s 3mm basswood. I wasn’t able to set up the air assist due to needing a nozzle, but I do have a honeycomb layer I used for this last test. I forgot I had it.

@MikeyH has been into it before, couldn’t you send your $$ settings, the whole thing? , the GRBL experts might be interested in that.

Hi Amy

Are there lights on the mainboard at the top of the machine and what is their status.

Are you using an accurate focusing tool/method.

I tried to find the depth of focus (DOF) for the LR5-10w but its not mentioned, But as the focal length is 50mm it is suggested that the DOF should be adequate.

If you were to re-run the cut until it does cut through, how many runs does it take.

Question to those who know! Could the laser-spot on the wall test be used here to check if both diodes are functioning.

The spot size is reported to be 0.6, If the beam is firing without air assist will the debris be cleared to allow continued cutting and could the lack of air assist have dirtied the lens and reduced effective power.

My first sheet of 5mm birch ply took 6 runs to cut through for the entire sheet and the second sheet which was same batch ended up taking 8 runs.

I just started cutting 4mm maple and wallnut and I’m up to 9 runs to be sure…Using the Snapmaker ray 20w..0.1 x 0.8 dot size.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.