I hope this “mechanical” question may find an answer. From the assembly videos I’ve seen, the Longer B1 36 uses toothless idlers, smooth, at the belt adjustment bracket. My design engineering background tells me that having a toothed belt run over a smooth idler pulley is NOT optimal as these belts were designed to run in a toothed “environment”. I’ll appreciate any comments and IF I may just be overthinking this issue, tell me that too. TWO quick answer needed for now - What is the hole/shaft size of the idler pulley used in the belt adjustment bracket?? AND the idler pulley WIDTH?? My B1 36 will be here tomorrow and if the consensus is that I should change the smooth idler pulleys for toothed, I can get these puppies ordered ASAP and not have to wait for first machine power up… Thanks in advance… Hank

I doubt whether running a toothed belt over a plain pulley tensioner would have any effect at all - the toothed pulleys are the ones that determine the position of whatever is being driven. Having said that, the plain pulley tensioners on my (home built) laser run on the smooth back of the belt, with the added advantage of making the wrap-around angle around the other toothed pulleys greater.

To my mind, the biggest problem with many of the smaller, cheaper lasers is that the pulley diameters are so small, meaning less teeth in contact with the belt, and the belt is asked to do a lot more flexing, which is probably not good in the long term.

By all means order new pulleys if you want, but carry on using the machine while you wait for the delivery!

The sproket on the motor end is toothed (obviouly)

The other end is tootheless for 2 reasons, all to do with how end users assemble and use these machines (most brands followed this brand)

a) if belts are not 100% microscopically aligned (specially on Y axis) tootheless iddler prevents banding to some extent

b) is much easier for the user to square the frame

c) Is cheaper, and the tooth on iddler do nothing favorable

Granted, when working on heavy mass CNC things are different, on small diodes the tooth idler is a meaningless part

I would suggest… dont try to fix it just yet! save your energies ![]()

Much thanks to all… Being retired from a career working for KSC, I have a tendency to “over engineer” common, everyday items it terms of " what does NASA require"? I’ll have to determine is this “fix” really necessary and just use as designed… (Don’t sweat the small stuff)…

i 100% get what you mean there ![]()

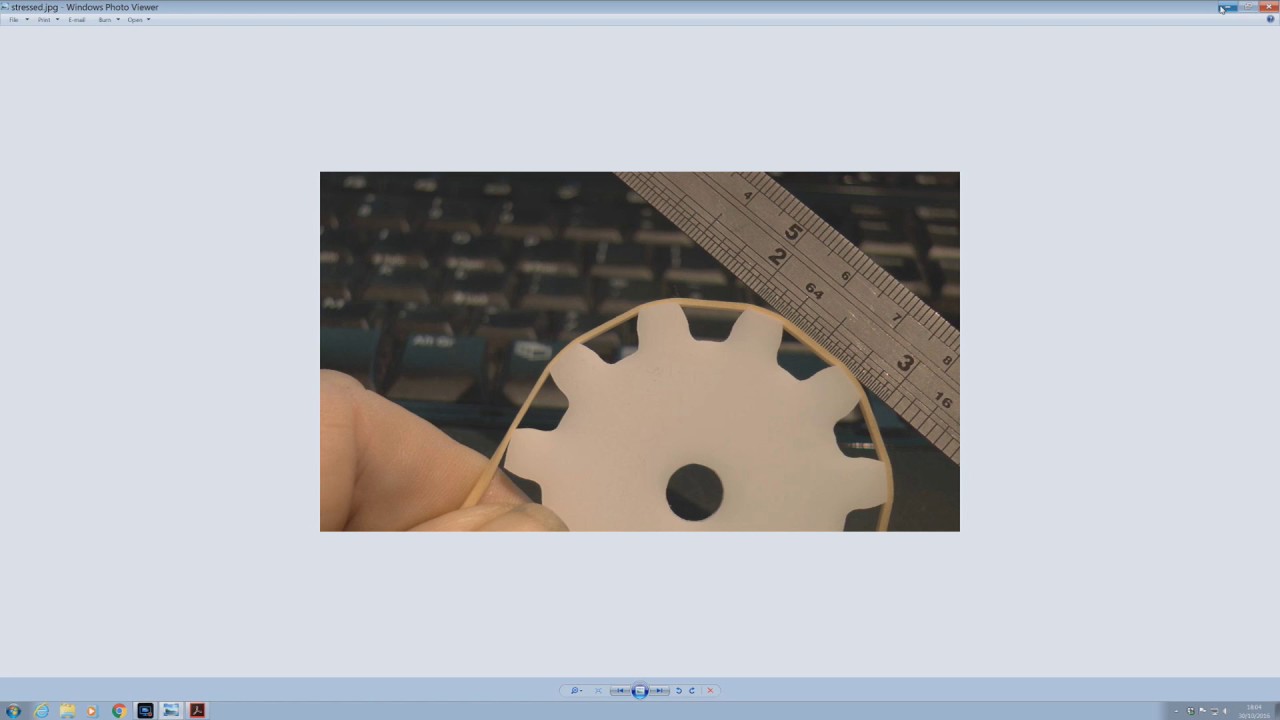

This was an attempt to fix a common problem on diode lasers that use GT2 belts and light frames.

They are prone to banding. The more “Humps” you put in the motion the worse it gets.

This is a non factor on bigger heavy machines because the inertia, weight and friction negate the small impact of the belt teeth

On 2020 extrusion thought…

You will have plenty to “optimize” as you use the machine so your tinkering brain will have work to do ![]()

I don’t think that’s really the issue… here’s a couple videos … kind of addresses what you’re talking about…

This is how it was solved …

He’s also a mechanical engineer - I like the way he puts things… have to put up with his Britt humor.

A new machine, I’d advise you to leave it stock until you get a feel for it… might find it’s a waste of time for functionality, but maybe a good academic trial to follow or decide to do your own thing… At least you’ll know how it works and learn from it… it will be a learning experience…

Good luck

![]()