We have two of these red and black “60 watt” machines.

Both are auto focus power Z axis. The Z axis is “u” on the control, and the control is a kt332.

These machines are not 60 watt. the tube amplifier only outputs 21milliamp guaranteed. we have one that puts out 22. If you want 60 watts you will have to buy another tube amp that goes to 30 milliamps and tune accordingly.

I tuned the amp so that when the control is calling for 99% power the amp is putting out its max 22milliamp.

from the factory when the control power hits 80% there is not change in laser power going up since at control power 80% you are at 21 milliamp.

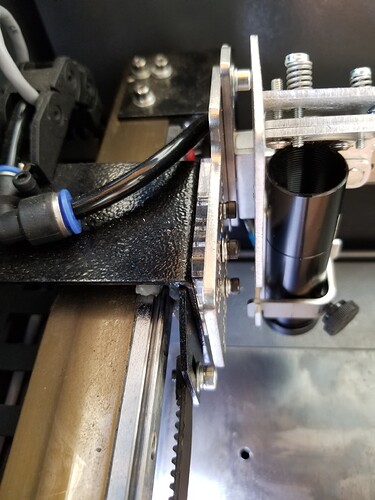

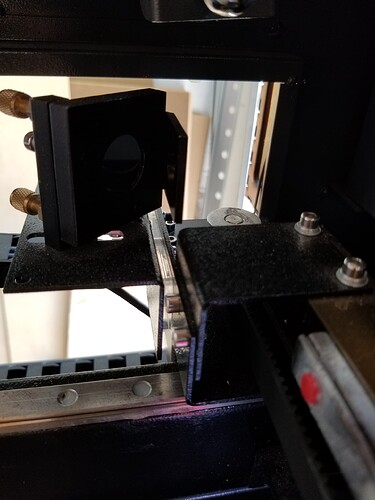

Next the red indicator for laser position is going to have to be replaced. We replaced ours with a kit that included the beam combiner, gold mirror, laser and mount. This required some mods and takes about 4 hours. I also put this on a toggle switch so the red indicator only runs when I need or want it.

For production and ease of setup, we added a grid setup plate with setup positions every one inch in x and Y. The cutting honey comb lays in on this for cutting jobs.

We added two srips of led lights, the back strip on a tilt switch so it goes off when you open the door and don’t blind you.

The included pond cooling system worked fine, but you have to enclose the water supply or it grows all kinds of nasty things. ultimately we got the two machine chiller.

You are going to have to fix the air assist. Order the $12 vlave from amazon and install using a needle valve. See above for more ideas. you will want to install a T on the cutting head and put a small amount of air to the mirror side of the head to keep the mirror from getting smoked.

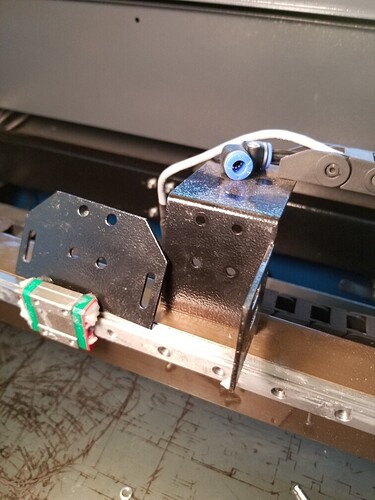

Head alignment… You are going to bump the head when you bump the head its going to be two hours of hell getting the head back right. I put magnetic breakaways on both machines… it saves tens of hours every week. just pick the head up off the table and snap back in place.

Lenses… just order 2.5" and 3" focal length meniscus lenses and some orings. the longer the focal lengh the more resonance you get, but the less focus variance.

exhaust… the more the better.

One of our machines is 12uM per step and one is 24uM per step… both work fine.

Leave the controls in metric… if you switch from metric to inches and then use light burn to change parameters There is no telling what kind of corrupted mess you are about to make. Just put the control in metric and leave it. put light burn in inches and when you change parameters completely shut the machine down and restart, you should be fine.

One machine came calibrated out of the box, one was off .125" in 8"

check bolts… bolts i frame assy of both machines were loose.

One day lightburn might run the “u” axis, but till then you have to manual your different z heights.

One water flow/pressure switch leaked… we had to take it out and tighten screws. Replace all the interior ziptie clamps before they leak.

clean and rust protect the rails every few days or you will have sqiggly lines.

These machines work great. The low end power is touchy and takes about 30-45 minutes warmup to stabilize.

Got the most of the other stuff, like the tubes and a few lenses from Cloudray.

Got the most of the other stuff, like the tubes and a few lenses from Cloudray.