Hi,

We have two laser tube one our machine:

- one 150W Reci W6 (called laser 2)

- one 50/60W no-name chinese laser brand (called laser 1).

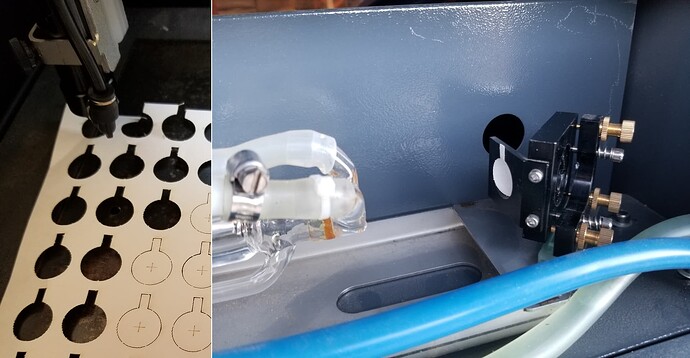

Recently we saw a lost of power on our 150W Reci tube… we were not able to cut as much as before. We though it was alignment / bad lens / old mirrors so we replace everything:

- new GaAs mirror

- we did try a GaAs lens

- we did do a perfect alignment of all three mirrors.

However results are quite poor still. For instance with our 50W/60W laser we are able to cut plywood 4mm at 20mm/s at 80% power.

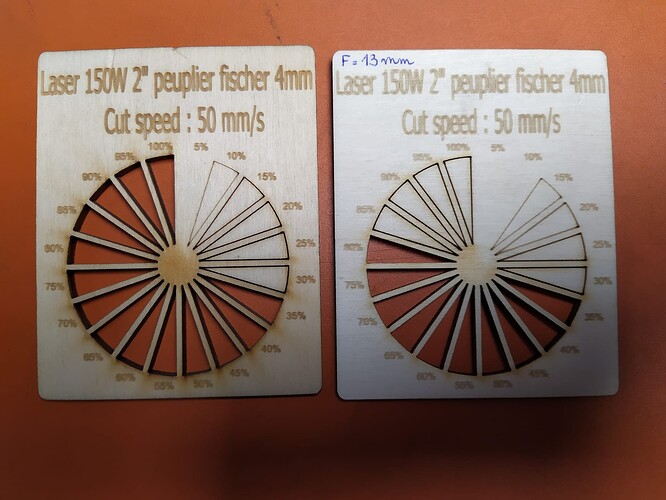

Today we did make some test we used to do before to compare with the 150W laser and we got strange results:

For example on the left it was test made 2 or 3 years ago when we got the machine. Today it was some tests made … the strange thing is that it seems to cut well between 30% and 75%/80% but nearly nothing at 90%. I checked the amperemeter at the same time and it appears taht it seems correct. We have approx 17mA at 50% while 35mA at 90%.

We did reproduce this strange phénomena with various lens and various thickness… for example on 10 mm plywood:

-

We are wondering if our 150W tube is dying and if should aim at replacing it or if we can fix this issue.

-

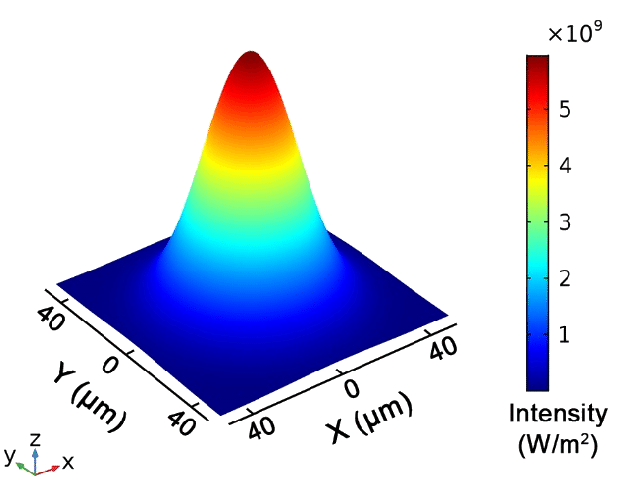

How can we explain this phenomena ?

-

Does somebody has a link to do advancerd checking on laser tube ?

-

What are reasonable setting for 4mm , 6mm, 10mm plywood for a 150W laser tube. Which speed should we aim at ?

Best regards