I am new to both Lightburn and Genmitsu, but have been using CNC routers for years.

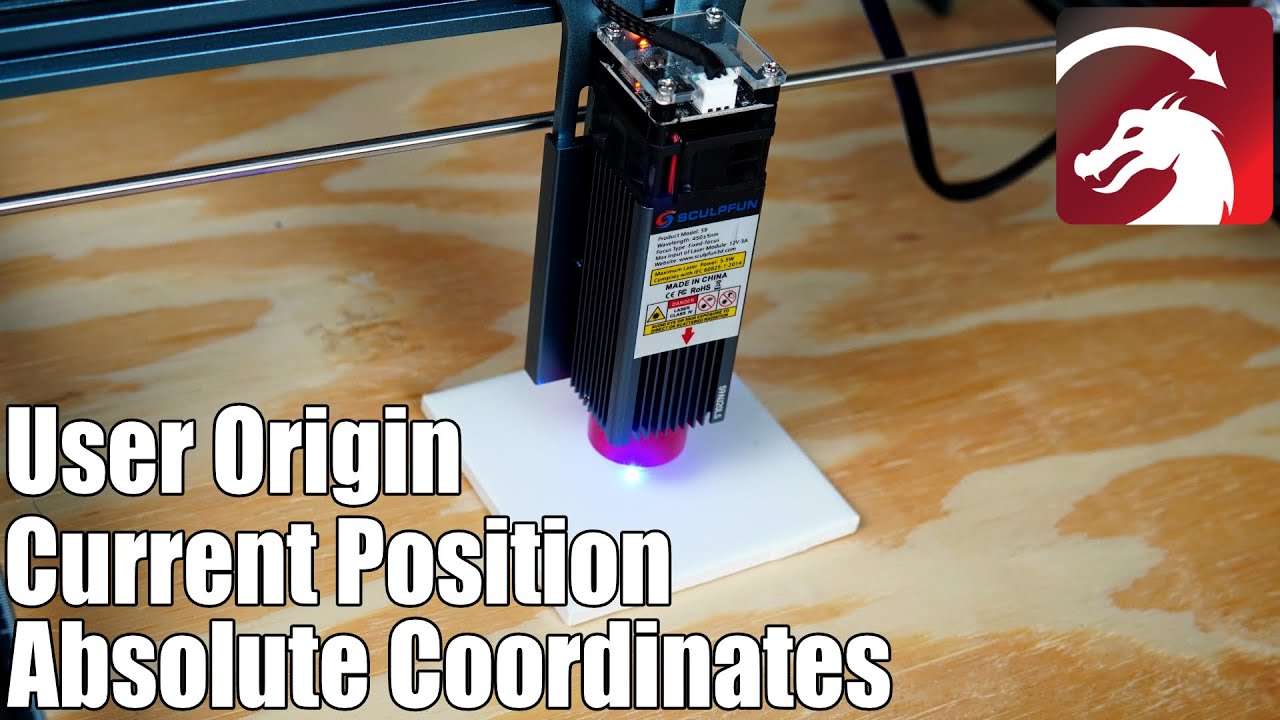

I am running a Genmitsu 4040 Pro Max with a 10 watt laser under Lightburn 1.7.06. I am running from a HP laptop under Windows 10 via USB to the GBRL controller. I had Lightburn find my controller and load the profile.

Issue 1. No matter what I do, the program always starts at the User Origin, even when I have ‘Absolute Coords’ selected.

Issue 2. The User (or Work) Coordinates always goes to the last ones used by a program other than Lightburn.

This means that both the ‘Clear Origin’ and ‘Set Origin’ don’t seem to be working within the Move tab in Lightburn.

When the Clear Origin is pressed, nothing shows up in the console.

When the Set Origin is pressed, this is what shows up in the console:

?

<Idle|MPos:14.700,162.506,0.000,50.001|Bf:35,253|FS:0,0|Pn:RHS|WCO:64.700,112.506,0.000,0.000>

ok

ok

When I use Candle instead of Lightburn to set the Work (or User) origin, this is what the console shows:

G10 L20 P1 X0 Y0 Z0 < ok

$# < [G54:122.300,364.306,-24.068,0.000]

[G55:0.000,0.000,0.000,0.000]

[G56:0.000,0.000,0.000,0.000]

[G57:0.000,0.000,0.000,0.000]

[G58:0.000,0.000,0.000,0.000]

[G59:0.000,0.000,0.000,0.000]

[G28:0.000,0.000,0.000,0.000]

[G30:0.000,0.000,0.000,0.000]

[G92:-120.000,-190.000,24.068,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000,0.000:0]

ok

Once the machine sees that sequence, the User Origin is set to the current location, but Lightburn uses that location for both Absolute Coords and User Origin.

Any ideas?