Good afternoon everyone. I searched the forum so apologies is this question has already been asked. I recently purchased the AtomStack M100-130W primarily to help me cut thin metal for plaques and of course to speed up my wood burning. The M100 advertised that it could cut thin metal, engrave on stainless and cut through pretty significant thickness of wood. The wood is going fine but when put very thin metal under it it wound even leave a mark even at the highest settings. Any help would be great.

Define thick in this case. I’ve heard of some of machines cutting through extremely thin sheets in the 0.001" thickness range. The results are not what I would consider clean either. These type of blue diode lasers are really not suited for metal cutting work and if that is your primary goal then I’d suggest cutting your losses now.

It should, however, be able to engrave stainless relatively well and indeed cut through some quite thick wood.

Thanks for response. Yes, I understand these are not the exact go to by any means for cutting metal but it’s hard to believe it won’t even make a mark. Also, AtomStack states it can cut 0.05mm thin metal. These plaque plates are very thin so I would expect it to atleast mar it up.

How thin and what is the material made from? 0.05mm would be in the category of extra heavy duty aluminum foil so quite thin. Anything reflective like aluminum, copper, brass is likely a no go. Stainless steel is likely to be a challenge for cutting through. You could try steel sheet.

Also, what types of settings are you using? You’d likely need to move excessively slow, in the 60 mm/min range or less.

The complete module requires 130W of power… the output is from 4 6W dpssl diodes… so ~20W…

Amazon call this Brass Metal Thin Sheet Foil

Atomstack claims to cut it and the displayed items look nice…

I wouldn’t attempt to cut that with my co2 either…

Good luck

![]()

I don’t see physically how this would even work. I assume anything that does cut will require a good bit of post-processing to make look presentable.

I have no clue either… it’s only a 20W output… and it’s visible light…

The dot size isn’t any smaller than my co2 with a compound lens…

![]()

It is less a matter of thickness, and more a matter of metal itself being seen as a mirror (whether dull or shiny.) Glass, plastics of nearly all kinds, wood and other vegative matter and stone and tile are seen by the CO2 laser beam as opaque, they readily absorb the energy of the laser, and either cut or at least leave a mark (referred to as “damage” by Russ Sadler. Metals on the other hand are seen as mirrors and reflect the beam away. Coating the metal with a material is the only way to mark metals with our CO2 lasers.

In our lab. We tested out the Atomstack M100 20W and the factory power supply is seriously under-powered for the laser head. The laser head is 192w and at 24v would at least require 8 amps. when we put two machines side by side one with the 5 amp factory power adapter and one with an 8 amp adapter the machine with the 8 amp adapter cut better and performed more like it was advertised than did the machine with the factory adapter machine. also clean lenses, proper focus, and setting come into play as well. Happy Sintering!

Today, while browsing around found replacement protective lenses for the M100 Atomstack for 3.00 USD each we ordered 20 and will test them out to see how they go

Please note that 130W power income ~ 20W optical power and this kind of LASER is absolutelly unable to cut metal.

Sculpfun S70 with 70W of optical power is reported to cut thin metal. But for this task the air assist needs to be replaced with high pressure compressor.

You can also use pure oxygen to increase metal cutting ability. But 20W optic power is too small. Some experiments could be done with 40W optic power.

For industrial metal cutting, it is needed equivalent energy around 1MW on 1cm^2.

Very off topic, but have a look at BWT’s “midrange” in the thunder series, checking in at 100kW!

The top of the line is 200kW, requiring 660kVA and weighing in at 3000kg

Looks not like a regular metal, but graphite. Graphite is easier to cut.

However, the video title is “BWT 100kW Fiber Laser Cutting (Thunder Series) Demonstration — Cutting of 100mm Stainless Steel”.

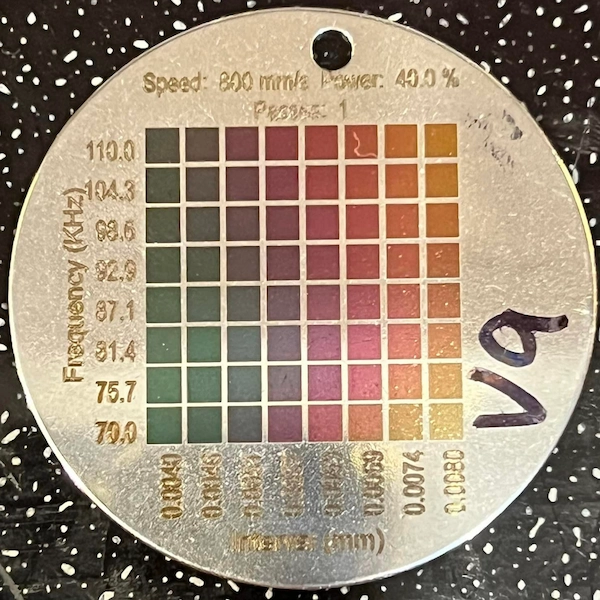

May be that it is some special black kind of stainless steel. It is much more interesting for us, that you can create color engraving on stainless steel and reach green, red magenta orange and yellow colors. We can do this with hobby grade LASERs.

PS: Previous example looks like carbon steel Fantastic LASER cutting here

If you would have 20kW, than you can cut metal like diode LASER cuts wood. This means 1000 times more powerfull. It seems that 6kW should be sufficient enough. Fiber LASER have efficiency 30%, so 6kW might mean 2kW of pure optical flow. And also prepare $20000 ~ $300000 for this device.