Hmm im not seeing any access panels outside anywhere…pretty nicely sealed inside as well. Im guessing maybe I take off the panel hiding the exhaust fan to expose it. Cant really find a diagram anywhere either which isnt surprising. It looks like you gotta remove the entire external shroud to do anything serious.

Oh wow. Didn’t realize it would be so inaccessible. Not entirely surprising I guess.

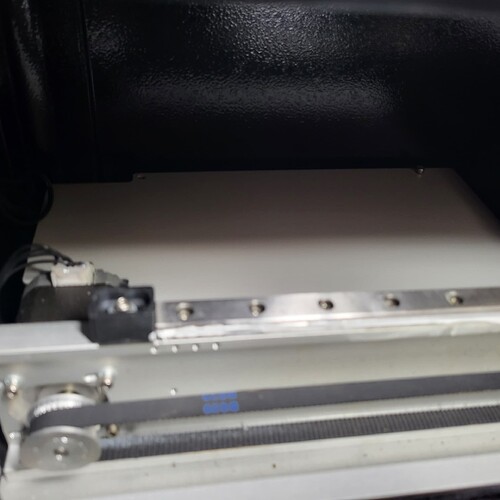

The 2nd pic you sent gave me a clue, i see a stepper motor and a y axis rail…i know where it hides. Give me a min to pop off 3 bolts.

100% true.

Mine arrived with no equipotential bonding on the electrical access panels, incorrectly matched protection devices, ie. circuit breakers & earth wiring, undersized DC power supplies and the ultimate NO-NO for appliance wiring; the main earth, connected to the IEC socket was fastened to the chassis with a bolt on top of the powder coating.

Bloody el. Thats not good

can you explain it a bit more, also which machine/brand is it about?

My laser is a generic Chinese Laser I purchased from a machinery importer located in Melbourne Vic. Australia.

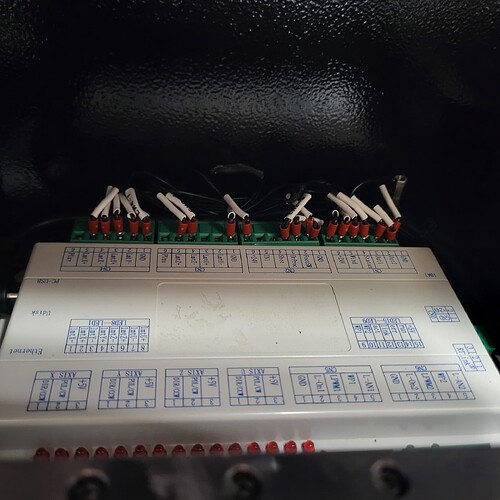

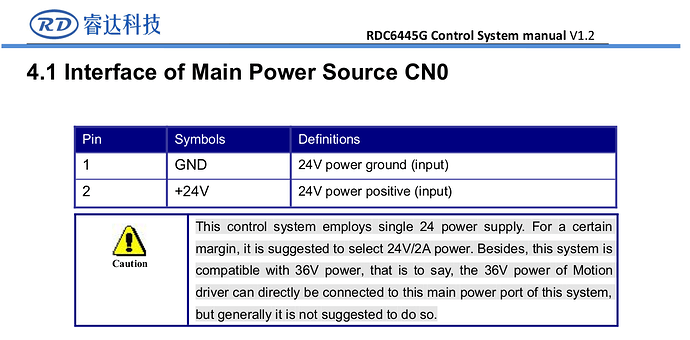

The 5V/24V DC supply installed in the laser was rated 24VDC\2A & 5DVC\1A. In the Ruida manual for the 4665G controller they state;

“This system adopts a single 24V power supply. It is recommended to use a power supply above 24V/2A”

It is saying that a 2 amp supply is not enough to power the controller and its outputs.

The 48VDC supply had no label at all, it just had 48V silk screened on the terminal board.

I don’t know of a 4665G (typo?) but I do have a manual for a 6445G …

The one I have states:

Sounds like it’s OK… are you seeing issues?

![]()

definitely a typo.

I swear, I think my mind is going on me…

I went out and found the power supply that was originally installed in my laser.

I took it out because it was a 1 amp supply, not 2A.

the manual I quoted from was the one with the touch screen.

It is a stupid error from the factory and could be advertised at the time of purchase.

But, how many machines do you think there are sold and the buyers have been running with their (under -dimensions) power supply - without being aware of it?

Of course, the problem does not make the problem less serious.

Under the line, I mean that everyone here in the forum that has laser machines comes 95% (?) of the machines originally from China and almost everyone knows what they have bought for their cheap money.

I also think most people are either satisfied or very happy with their cheap Chinese machines - isn’t that strange?

There are many emotions in this thread and the very meaning of the headline has disappeared.

My answer to the very first question is:

If you represent a public institution such as schools or Maker Space or similar, buy a machine that is produced and serviced in the West and pay the price.

Are you a private person with either business or hobby, buy one of the most recognizable Chinese brands on the market and save a lot of money.

If you are not prepared to spend time getting to know the machine and you are not willing or able to service the machine - then do not buy a laser machine, it is too dangerous and you will never operate the machine properly.

This applies to all machines.

I would also add that your new laser is going to turn a lot of your material into scrap. That is the tuition you pay for learning something new. If you aren’t willing to see your money literally go up in smoke then maybe a laser isn’t for you.

Correct ![]() , and there should be no doubt, I love smoke and laser lights, I just need some shares in a sawmill.

, and there should be no doubt, I love smoke and laser lights, I just need some shares in a sawmill. ![]()

@bernd.dk is correct and most of us can make addenda to his advise.

It’s very possible to purchase one of these and be stuck with their proprietary software, unable to run Lightburn… It’s good to note their software has speed settings in percentages not mm/s…

This makes it much harder to teach people how to use them.

This link is an example of this issue. There are plenty more.

Great advise, however many sites, like Cloudray.com and OMTechLaser.com explicitly state, from the OMTech link.

This limited warranty does not apply to OMTech-branded products purchased from third-party websites such as Amazon or eBay.

Cloudray is similar

Cloudray Official Website (www.cloudraylaser.com) and Cloudray Store on Amazon / eBay/ Aliexpress are different teams that all operate independently. We don’t offer after-sale tech support for any order from Cloudray store on Amazon/eBay/ Aliexpress as we are not linked to each other.

Many people have complained about this and blame them, however they state it clearly. Amazon and Ebay do not state they are unwarranted from the main site. If you have issues for warranty or support they will send you back to the Amazon or Ebay site.

This may be a bit steep. Glowforge and to a lesser extent the OMTech Polar and Gweike Pro competition are for people who want to lase stuff without knowing anything about lasers or how they work. So there is a path, albeit more expensive in more ways than one.

I’d add, if you are afraid of them, don’t buy one. Nothing is worse than a driver of a vehicle that continually brakes for no reason other than fear …

There is nothing safer than knowledge combined with common sense…

@cggorman is correct, I’m wading through burnt or incomplete engravings… really hurts to throw away stuff you paid for.

Sounds like you should own a smoked bbq/disco business. ![]()

![]()

Thanks everyone

I think i fit in the [quote=“bernd.dk, post:52, topic:124578”]

private person with either business or hobby, .

[/quote] category.

New to lasers but willing to learn while keen not to buy anything likely to set my studio on fire because its been made/wired badly.

Happy to pay a bit more to avoid having to put stuff like that right out the box .

Have heard lots of good stuff about the boss lasers. Some people advised to look at haotian and g.weike machines as they apparently make the boss ones which boss then badges. But think i feel more confident buying from boss as all seems more customer friendly /commercial service etc.

I know ill pay through the nose a bit for that decision.

Thanks also for heads up on material wastage. I imagine itll be costly and long learning curve but im ready for it!

It’s literally just the exhaust fan. You unscrew it, that’s all. And then you install a decent one close to where ever you will push the air outside. It’s literally one of those cooking fume hood air extraction units, nothing complicated, nor dangerous to do. It’s just the two power cables ![]()

RF is way faster at engraving, and has higher detail as well. It’s equally capable of cutting as a CO2 glass tube. It’s just that for the price of the RF you can get a more powerful glass one that is more capable at cutting. But 40W is 40W, RF or glass ![]()

You are taking this WAY out of context. The included fans are generally pretty sh*tty anyhow (loud/inefficient), so people more often than not replace these. For what it’s worth, you’ll have to attach the exhaust fan manually anyhow, whether factory or after-market. So if you don’t think you can handle the after-market, you most likely won’t be able to handle the rest either. The fan install is the least of your worries…

If you want to go for a Boss, just get a Thunder laser instead. Check some comparison videos online, and you’ll see why ![]()

RF excited machines are considered the ultimate co2 machine. However I’d argue this is relative to what you are doing and how deep your pockets are.

The machine I have and originally picked out was a 50W OMTech China Blue… A delivered price of ~$2k US. It turned out to be closer to 40W machine and OMTech knew that.

An RF laser, 40W module costs over $2,600 just for the module. This chilled me out a bit.

On one of the sites, a business in California had one, as I was going to Disneyland, he invited me to come see both the dc excited and rf excited machines he used.

I was there about 5 hours… the co2 ran the whole time I was there. I asked about the hearing muffs on the wall. Then he turned on the rf machine, which are air cooled…

I understood why he kept hearing protection around the machine. The rf machine was never used the whole time I was there… he stated he used it on plastics that needed a higher precision than the glass tube model could produce. Wasn’t wise enough to pick his brain for more information… But I immediately discarded the notion of an rf type machine.

The rf machine commonly has a better beam quality…

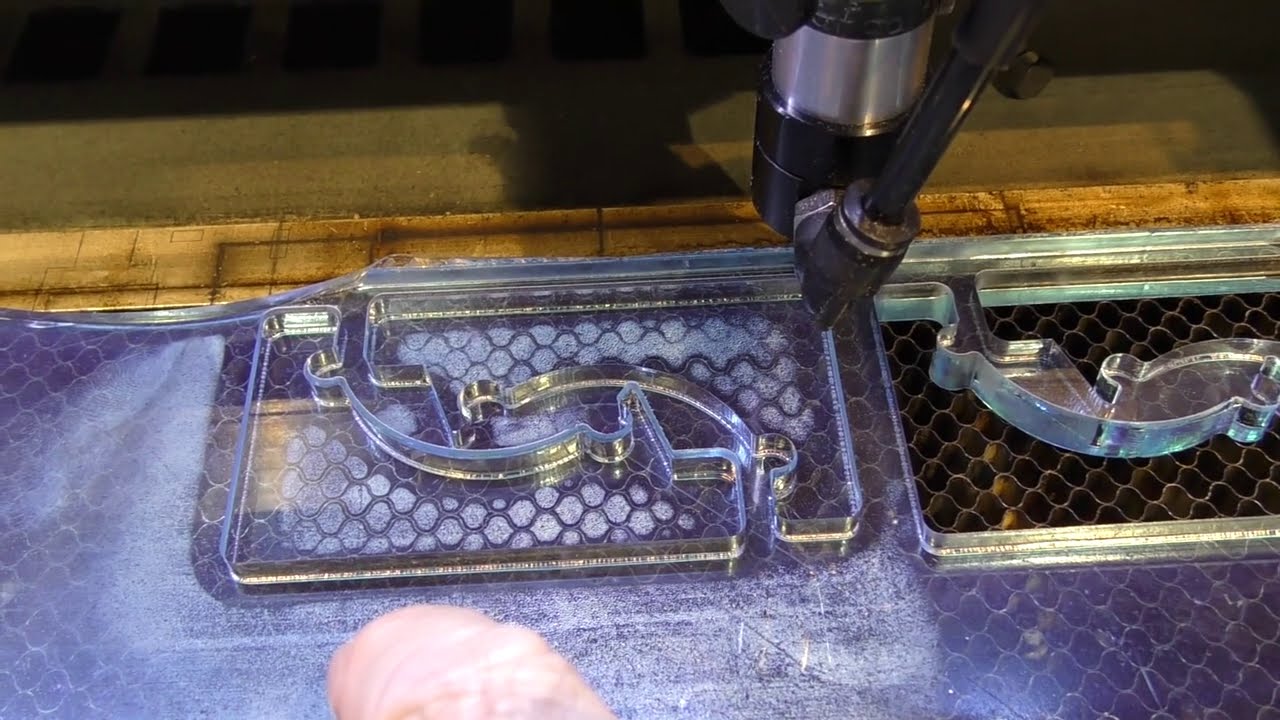

Of these, the only safety issue he had was the unattended machine caught fire and burnt down a piece of the business. As usual, it was the honeycomb bed.

If you are worried about safety, you need to compare it to something you can relate too.

If you drive a car, I’d make book on your changes of injury in a vehicle would greatly exceed that caused by these machine. Even taking into account the number of vehicles compared to the number of hobby lasers. We lose about 40k lives a year in the US and countless numbers of injuries from non-fatal collisions.

Safety is between your ears, not provided by some kind of gizmo or protection system. It’s becoming Lackadaisical around these machines that causes injuries.

Understand how they work and you’ll know what the safety issues are.

In the end buy what you want and can afford. If you want a Boss, then get that…

When it’s all over, we don’t have to live with your choice, you do… please purchase a co2 extinguisher for fire control… I keep a 5lb one around and move it to the fiber when I’m using it.

Good luck

![]()

I beg to differ.

THIS is the reason the sh*t burned down:

You can’t buy a machine specifically made to burn things and then get mad when it burns things when you leave it unattended…

I can’t speak to all RF lasers but I’ve stood next to a Thunder Laser Bolt while it was burning thin paper. I didn’t notice hardly any noise at all from the machine and could carry on a conversation easily while it was burning. Don’t know if fan speed is variable based on power use or what so can’t speak to more scenarios. Noise was definitely lower than my combined air assist, extraction fan, cabinet fan, and water cooler combined volume.

I don’t know either about the noise level change, but compared to my glass tube it was terrible.

I haven’t been around a lot of rf types, so it’s more than possible I got a loud one in this case. It surprised me he didn’t really seem to use it. I would have thought he’d have used it more than the glass model that was running, but he didn’t.

I can also beg to differ, not being there was not the cause of the fire, it was the honeycomb that started it.

Being unattended was only a resulting contributing factor to the accident. This seems to be pretty common in industry. One of the guys has a business in Tempe and showed me a photo of his last machine after it went up in flames.

They saw it catch and was only a few yards away and he lost the whole machine. Didn’t burn down his shop, it was the honeycomb that caught fire and even being that close they couldn’t save the machine. This was his explanation… Not mine, I wasn’t there.

Most people go stir crazy watching a machine doing the same thing over and over for an 8 hour shift. There, most likely, would never have been a fire at all without the honeycomb bed.

I run mine with a steel sheet, not honeycomb. I’ve never seen flames in mine.

If you can show me a good use for one of these honeycomb beds, I’d love to know. I found them extremely damaging to air flow across the machine.

You’d think, as I did, they’d be great for cutting, but even with air assist very little air flow makes it through the lasers kerf and debris just lingers in each of the spaces where it condenses, becoming a fire hazard.

These videos shows you what’s happening. It’s about 3 minutes…

This ones about 15 minutes…

I found them useless, which is why I stated if you can find a good use for them I’d love to know about it. I have mine kicking around somewhere… for what they cost, couldn’t bear to pitch it out. I lasted a day with mine, then went to a sheet of steel… Been very happy with it.

In the end you get to pick what you use…

Have fun…

![]()