Mind you that I said the reason the thing burned down was because it was left unattended. Being there won’t stop fires from starting, but you sure as hell can put them out a lot better than if you’re not there (in time).

The honeycomb didn’t start the fire either, the Machine-That-Burns-Things Started the fire. Did the honeycomb made it easier? MAYBE. Was it the cause? NO.

If you leave the machine unattended for long enough that it can burn down beyond saving, you’ve left it unattended for too long.

Stay in the same room, and have measures in place to prevent/stop fires from getting out of control. Want to leave the room? Pause the machine, simple as that.

You can’t plame a piece of oddly shaped metal for starting a fire. It’s the human’s fault who doesn’t know how to operate their equipment, nothing else’s.

FWIW, I run knife slats on my 24x48", and only ~4 of them. Sh*t catches fire all the time, because that’s what the machine is made to do.

This is dangerous, as people who haven’t got a clue will rip out their honeycomb, and take a nice long walk while their machine gladly burns their house down. With AND without honeycomb…

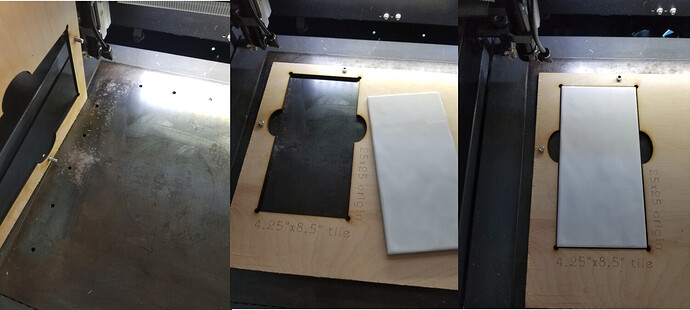

Cutting tiny pieces you don’t want to fall through to get lost, or burnt. Or better still, tilt in their hole, so the laser can jam into it and cause… fires.

For someone who claims to have only used theirs for a day, I find it odd that’d you’d give out such false (and simultaneously dangerous) advice, given the lack of experience on the matter.

But hey, this is the internet, so who cares, right?